5 Reasons to Choose Best Nordmkygearbox for Your Industrial Needs

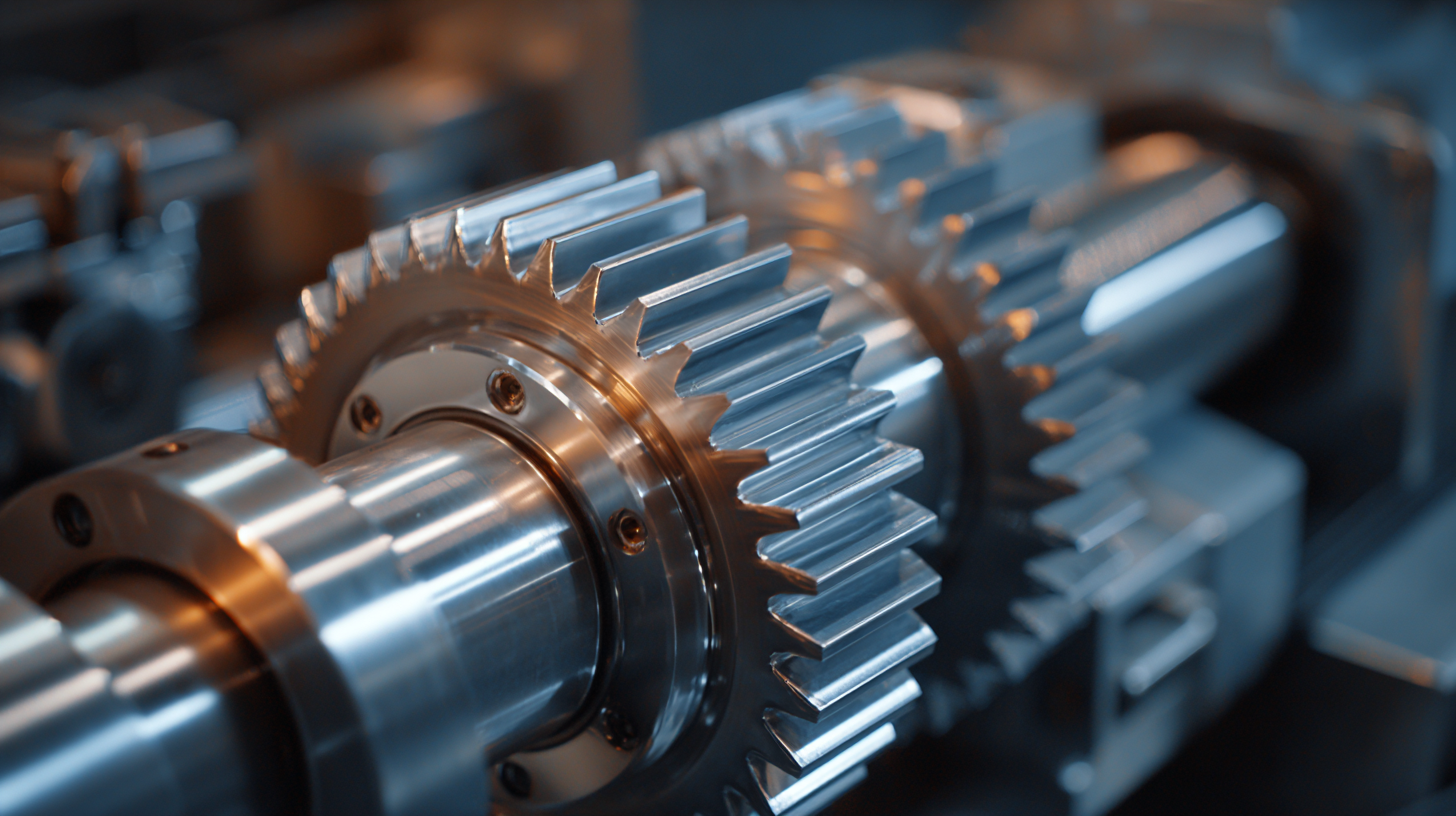

In today's competitive industrial landscape, choosing the right equipment is crucial for optimizing performance and efficiency. Among the myriad of options available, the Nordmkygearbox stands out as a top choice for various industrial applications. This advanced gearbox is known for its exceptional durability, precision engineering, and versatility, making it suitable for a wide array of settings—from manufacturing plants to automation systems. In this blog, we will delve into five compelling reasons why the Nordmkygearbox should be at the forefront of your industrial needs. Whether you are looking to enhance productivity or ensure reliable operations, understanding the technical specifications and advantages of this gearbox can significantly impact your outcomes. Join us as we explore what makes the Nordmkygearbox a preferred selection for industries worldwide.

Reasons Why Nordmkygearbox Stands Out in the Industrial Sector for 2025

In the ever-evolving industrial sector, selecting the right gearbox can significantly impact operational efficiency and productivity. Nordmkygearbox has emerged as a leading choice in 2025, primarily due to its unwavering commitment to quality and advanced engineering. According to a recent report by Grand View Research, the industrial gearbox market is projected to reach $40 billion by 2027, driven by the growing demand for efficient and durable solutions. Nordmkygearbox stands out specifically for its high-load capabilities and adaptability across various applications, positioning itself as a reliable partner for industrial operators.

One significant advantage of Nordmkygearbox is its innovative design that minimizes energy loss, a crucial factor as industries strive for greater sustainability. Data from the International Energy Agency suggests that improving energy efficiency in industrial systems can reduce energy consumption by up to 30%. Furthermore, Nordmkygearbox’s reliability and extended service life contribute to lower maintenance costs, aligning with industry trends emphasizing cost-effective solutions. By leveraging cutting-edge technology and rigorous testing standards, Nordmkygearbox not only meets but exceeds the demands of modern industrial applications, solidifying its reputation in 2025 and beyond.

5 Reasons to Choose Best Nordmkygearbox for Your Industrial Needs

Key Innovations of Nordmkygearbox Tailored for Industry Professionals in 2025

In the constantly evolving landscape of industrial solutions, the upcoming innovations in gearbox technology are pivotal for industry professionals aiming to enhance operational efficiency. The Nordmkygearbox stands out in 2025 with its commitment to smart engineering and advanced automation features. One of the key innovations is the integration of IoT capabilities, allowing real-time monitoring and remote diagnostics. This connectivity not only reduces downtime but also optimizes maintenance schedules, ensuring that equipment runs smoothly and efficiently.

Additionally, the focus on energy efficiency within the Nordmkygearbox design is remarkable. By implementing advanced materials and streamlined designs, the gearboxes are engineered to reduce energy consumption significantly while maintaining high-performance levels. As the industrial gearbox market is projected to grow at a CAGR of over 4.6% from 2025 to 2032, the introduction of such innovative gearboxes aligns perfectly with industry demands for sustainability and cost-effectiveness. These advancements will be instrumental for professionals seeking reliable and cutting-edge solutions to meet their operational challenges in the coming years.

Understanding the Benefits of Durability and Reliability in Nordmkygearbox

When it comes to industrial applications, durability and reliability are paramount.

Nordmkygearbox has established itself as a leader in the gearbox industry, offering robust solutions that withstand the rigors of demanding environments.

One of the key benefits of choosing Nordmkygearbox is its superior construction, utilizing high-quality materials designed to resist wear and tear.

This not only extends the lifespan of the gearbox but also reduces the frequency of maintenance, allowing businesses to focus on their core operations without the disruptive downtime caused by equipment failure.

Reliability is another critical reason to opt for Nordmkygearbox.

These gearboxes undergo rigorous testing to ensure they can handle extreme conditions and heavy loads without compromising performance.

The consistency of their output, regardless of the operational pressures, guarantees that machinery operates smoothly.

This unwavering reliability translates into increased productivity, reduced operational costs, and ultimately, a stronger bottom line for businesses relying on precise and steady performance in their industrial processes.

How to Select the Right Nordmkygearbox for Your Specific Industrial Applications

When selecting the right Nordmkygearbox for your specific industrial applications, it's crucial to consider the compatibility of the gearbox with your existing machinery. Begin by assessing the operational requirements of your equipment, including speed, torque, and load capacity. Understanding these parameters will help you narrow down options that can effectively handle the demands of your setup. Additionally, evaluate the environment where the gearbox will be used. Factors such as temperature extremes, exposure to moisture, and the presence of corrosive substances can significantly impact the longevity and performance of the gearbox.

Another critical aspect is the materials and design of the Nordmkygearbox. Opt for gearboxes made with high-quality materials that enhance durability and reduce wear over time. The design should also facilitate ease of maintenance. Look for features such as sealed bearings and simple access points, which can streamline servicing and minimize downtime. Finally, consult with manufacturers or suppliers who can provide personalized recommendations based on your specific industrial needs, ensuring you make an informed decision that aligns with your operational goals.

5 Reasons to Choose Best Nordmkygearbox for Your Industrial Needs

| Feature |

Description |

Application |

| Durability |

Designed for heavy-duty use with robust materials. |

Manufacturing, Mining |

| Efficiency |

High efficiency gear design minimizes energy loss. |

Conveyor Systems, Robotics |

| Customization |

Available in various sizes and configurations to meet specific needs. |

Automotive, Packaging |

| Maintenance |

Designed for easy maintenance and long service life. |

Food Processing, Chemical |

| Performance |

Consistent performance under varying load conditions. |

Textile, Petrochemical |

2025 Trends in Gearbox Technology: What to Expect from Nordmkygearbox

As we look ahead to 2025, the trends in gearbox technology are evolving at a rapid pace, and Nordmkygearbox is at the forefront of these innovations. One of the most significant trends is the increasing demand for energy efficiency. Industries are adopting advanced gearbox designs that reduce energy consumption while maintaining optimal performance. Nordmkygearbox has made substantial strides in incorporating lightweight materials and advanced engineering methods to achieve this goal, making their products an ideal choice for environmentally conscious manufacturers.

Another key development is the integration of smart technology in gearbox systems. The rise of the Internet of Things (IoT) and predictive maintenance has led Nordmkygearbox to implement intelligent monitoring systems that provide real-time data on gearbox performance. This technology not only helps in minimizing downtime but also allows for more proactive maintenance, ultimately prolonging the lifespan of the equipment. As companies strive for automation and enhanced performance, Nordmkygearbox stands out as a reliable partner in adapting to these trends, ensuring that industrial operations remain competitive and efficient.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor