Top 10 Bevel Helical Gearmotors for Optimal Performance in 2023

In the realm of industrial machinery and automation, the choice of drive components can significantly influence operational efficiency and overall performance. One key player in this domain is the Bevel Helical Gearmotor, renowned for its unique design that facilitates smooth power transmission while effectively minimizing backlash. As industries evolve, the demand for robust and high-performance gearmotors continues to rise, leading to innovations and enhancements that cater to various operational needs.

Selecting the right Bevel Helical Gearmotor can lead to improved productivity, reduced maintenance costs, and increased longevity of equipment. This guide aims to highlight the top ten bevel helical gearmotors available in 2023, each meticulously evaluated for their performance, durability, and efficiency. By examining these standout options, manufacturers and engineers can make informed decisions that align with their specific applications, ensuring optimal system integration and performance. Whether for conveyor systems, robotics, or other heavy-duty operations, understanding the capabilities of these gearmotors can transform workflow dynamics and enhance operational capabilities.

Overview of Bevel Helical Gearmotors and Their Applications

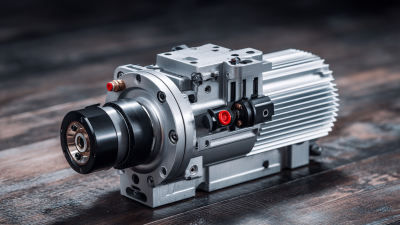

Bevel helical gearmotors are a crucial component in various industrial applications, known for their efficiency and ability to handle high torque loads. These gearmotors combine the angular orientation flexibility of bevel gears with the smooth operation and power transmission characteristics of helical gears. This unique design allows them to be used in a wide range of applications, from conveyor systems in manufacturing to power transmission in robotics.

Their compact design and ability to operate quietly make them suitable for environments where space and noise control are critical.

When selecting bevel helical gearmotors for specific applications, consider factors such as load requirements, speed, and environmental conditions. Understanding the operational context can significantly enhance productivity. For instance, in applications that require frequent start-stop operations, gearmotors with higher torque ratings will perform better over time, reducing wear and prolonging service life.

Tips: Always ensure that the gearmotor is adequately matched to the load it will operate against, and take into account any potential temperature variations that might affect its performance. Regular maintenance checks can also help identify any wear or misalignment early, ensuring optimal performance and minimizing downtime.

Key Features of High-Performance Bevel Helical Gearmotors

When selecting bevel helical gearmotors for optimal performance in 2023, there are several key features to consider. First and foremost, efficiency is paramount; high-performance gearmotors exhibit minimal energy loss during operation, translating to reduced operational costs and prolonged lifespan. Look for gearmotors with high gear mesh accuracy and low backlash, which ensure smooth transmission of torque and enhance overall system reliability.

Another crucial feature is the torque-to-weight ratio. Advanced lightweight materials and innovative design reduce the size and weight of the gearmotors while maintaining high torque output. This is particularly beneficial in applications where space is limited or where minimizing the weight of machinery is critical. Additionally, adaptability to various environments, including those exposed to extreme temperatures and harsh conditions, is essential for uninterrupted operation.

Lastly, superior lubrication systems play a pivotal role in the longevity and efficiency of bevel helical gearmotors. High-performance models are designed with advanced lubrication technologies that reduce wear and friction, ensuring peak performance even under continuous operation. By focusing on these key features, industries can achieve significant improvements in efficiency and reliability, making bevel helical gearmotors an invaluable component in modern mechanical systems.

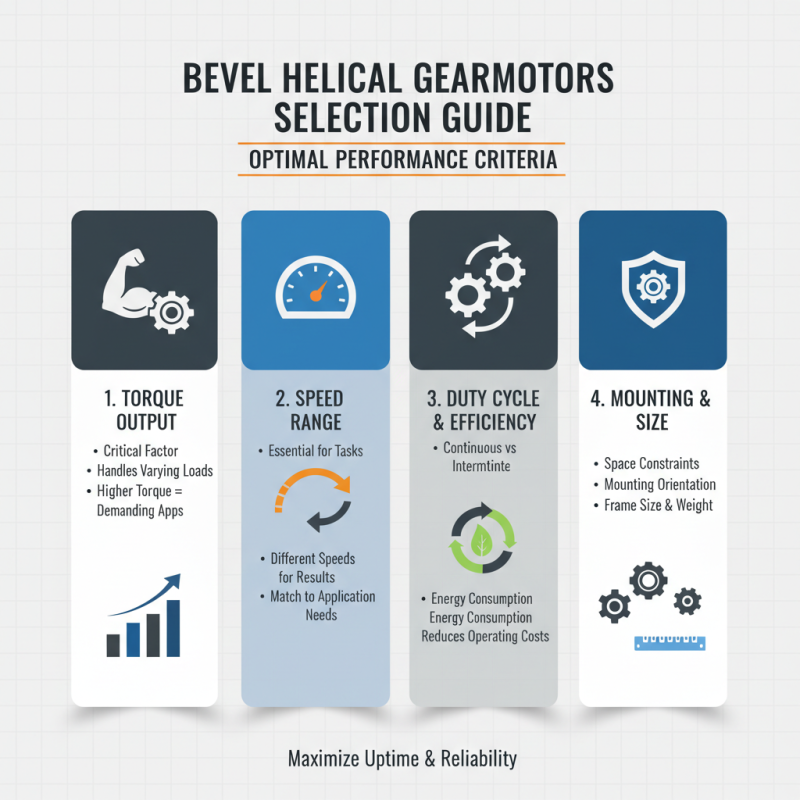

Top Criteria for Selecting the Best Bevel Helical Gearmotors

When selecting the best bevel helical gearmotors for optimal performance, several key criteria should be considered to ensure that the chosen product meets specific application needs. First, the gearmotor's torque output is a critical factor, as it determines the motor's ability to handle varying loads effectively. Higher torque ratings generally correlate with better performance in demanding applications. Additionally, understanding the speed range of the gearmotor is essential, as different tasks may require different operational speeds to achieve desired results.

Another important aspect to evaluate is the efficiency of the gearmotor. High-efficiency models not only save energy but also reduce operational costs over time. It’s beneficial to look for gearmotors that minimize energy losses through optimized gear design and lubrication systems. Moreover, the construction and material quality of the gearmotor significantly affect its durability and lifespan. Selecting models with robust housing and high-quality gears can lead to lower maintenance costs and longer service life, which is vital for industries reliant on continuous operation. Lastly, compatibility with existing systems and ease of installation should also be factors in the selection process, as they influence the overall feasibility of integrating a new bevel helical gearmotor into current workflows.

Review of the Top 10 Bevel Helical Gearmotors of 2023

In 2023, the demand for bevel helical gearmotors continues to rise, leading to innovative advancements in performance and efficiency. These gearmotors are favored across various industries due to their ability to provide high torque output while maintaining a compact design. As we review the top 10 bevel helical gearmotors, it becomes evident that factors such as energy efficiency, precision engineering, and enhanced durability are key features to consider.

Among the notable models this year, several standout options demonstrate exceptional performance across different operational environments. Many of these gearmotors incorporate advanced gearing designs and superior materials, thus ensuring better power transmission and reduced noise levels. Users are increasingly prioritizing these features to enhance overall machinery performance, leading to increased productivity and lower operational costs. As industries evolve, selecting the right bevel helical gearmotor becomes critical in achieving optimal operational efficiency.

Comparison of Best Brands and Models for Bevel Helical Gearmotors

In the dynamic world of industrial machinery, bevel helical gearmotors have emerged as vital components for enhancing operational efficiency. The 2023 landscape highlights a competitive selection of gearmotors that excel in torque capacity, speed control, and energy efficiency. According to the latest industry reports, the demand for high-performance gearmotors has surged by approximately 15% this year, driven by advancements in automation and manufacturing processes. Key metrics such as power density and thermal efficiency indicate a shift towards gearmotors that not only provide robust performance but also contribute to energy savings.

When evaluating the best models, factors such as gear ratio precision, lubrication type, and materials become increasingly important. Research shows that advanced gearmotors using synthetic lubricants can improve lifespan and maintain operational efficiency by reducing friction and heat generation. Moreover, the integration of smart technology has enabled real-time monitoring, allowing operators to optimize performance and reduce downtime.

**Tips:** When selecting a bevel helical gearmotor, consider the application requirements, including load characteristics and operational environment. Additionally, always review technical support and warranty options, as these can be critical for long-term performance. Regular maintenance and monitoring can significantly enhance the lifespan of gearmotors, ensuring they function at peak efficiency for years to come.

Top 10 Bevel Helical Gearmotors for Optimal Performance in 2023

| Model |

Power (kW) |

Output Speed (RPM) |

Gear Ratio |

Efficiency (%) |

Weight (kg) |

Price (USD) |

| Model A |

1.5 |

1500 |

10:1 |

90 |

25 |

450 |

| Model B |

2.0 |

1200 |

15:1 |

92 |

30 |

550 |

| Model C |

0.75 |

1800 |

20:1 |

88 |

20 |

350 |

| Model D |

3.0 |

1000 |

8:1 |

91 |

35 |

600 |

| Model E |

1.8 |

1450 |

12:1 |

89 |

28 |

500 |

| Model F |

2.5 |

1300 |

6:1 |

93 |

40 |

700 |

| Model G |

1.2 |

1600 |

25:1 |

87 |

23 |

400 |

| Model H |

0.5 |

2000 |

30:1 |

85 |

18 |

300 |

| Model I |

2.2 |

1100 |

4:1 |

94 |

45 |

650 |

| Model J |

1.9 |

1400 |

5:1 |

90 |

32 |

520 |

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor