Ultimate Checklist for Choosing the Best Gearbox Innonomotics Gearmotor for Your Needs

In today's rapidly advancing industrial landscape, selecting the right gearbox innonomotics gearmotor is crucial for optimizing operational efficiency and performance. With the global electric motor and gear market expected to reach USD 170 billion by 2027, the demand for high-quality gearmotors is at an all-time high. According to a recent report by MarketsandMarkets, the growth of automation across various industries, including manufacturing, automotive, and renewable energy, drives this trend, highlighting the importance of selecting a gearbox that meets specific application needs.

Whether you're dealing with heavy-duty machinery or precision applications, understanding the unique features and suitable applications of different gearmotors is essential. This ultimate checklist will equip you with the knowledge to make an informed decision and ensure that your choice of gearbox innonomotics gearmotor aligns perfectly with your operational requirements.

Understanding the Importance of Gearbox Selection for Optimal Performance

Selecting the right gearbox is crucial for ensuring optimal performance in various applications, from industrial machinery to robotics. According to a report by Research and Markets, gearbox solutions are projected to grow by 6.8% annually due to their increasing significance in enhancing energy efficiency and reliability. A well-chosen gearbox not only improves the overall functionality but also contributes to reduced maintenance costs and downtime, which can be detrimental to production efficiency.

When evaluating gearboxes, consider factors such as load capacity, speed requirements, and environmental conditions. Consulting the manufacturer's specifications can provide insights into the performance metrics necessary for your specific application. For instance, a gearbox that operates effectively within a specific temperature range can prolong its lifespan and performance.

**Tip:** Always assess the torque requirements and match them with the gearbox specifications to avoid failure and maximize the system’s lifespan.

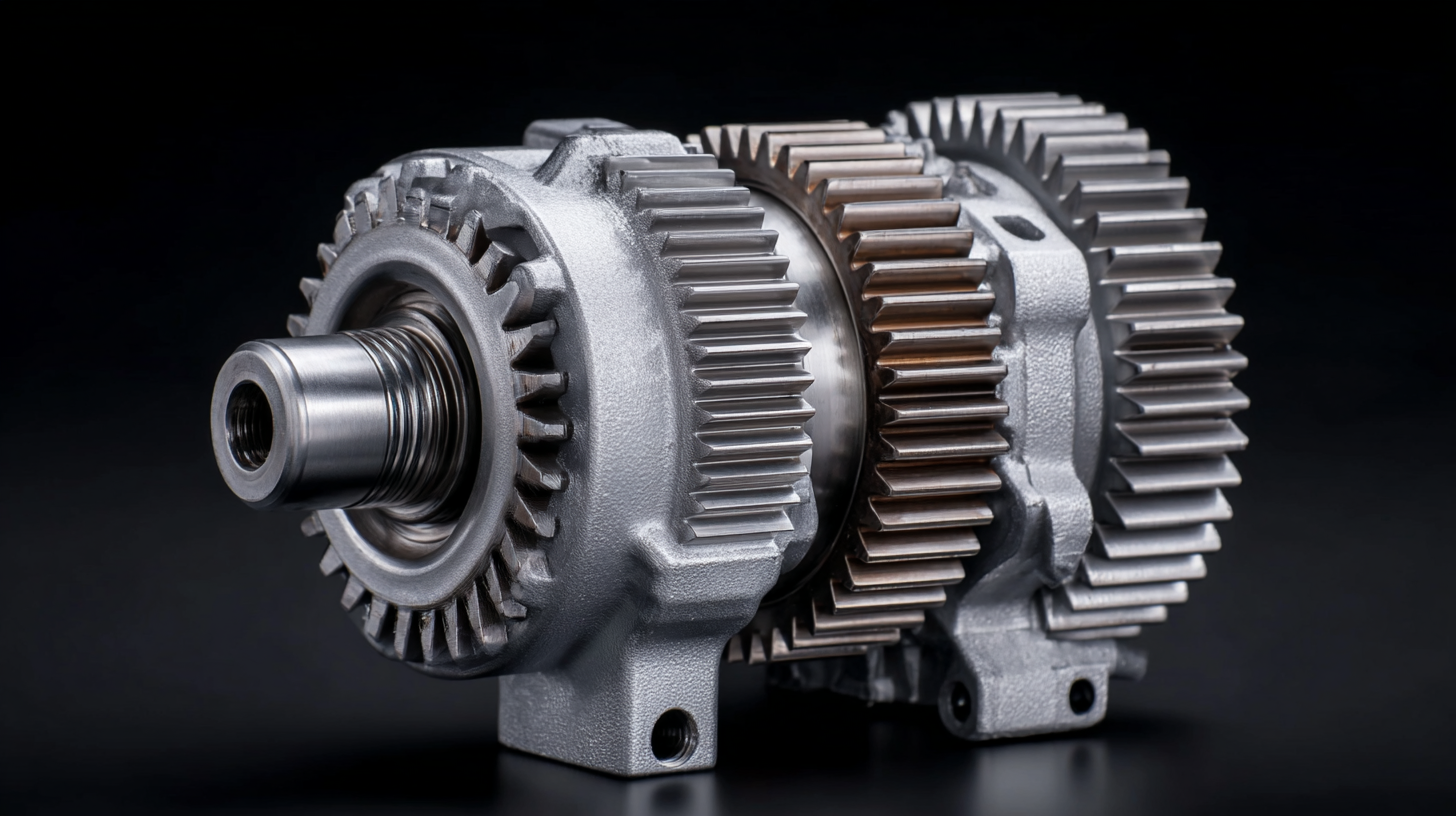

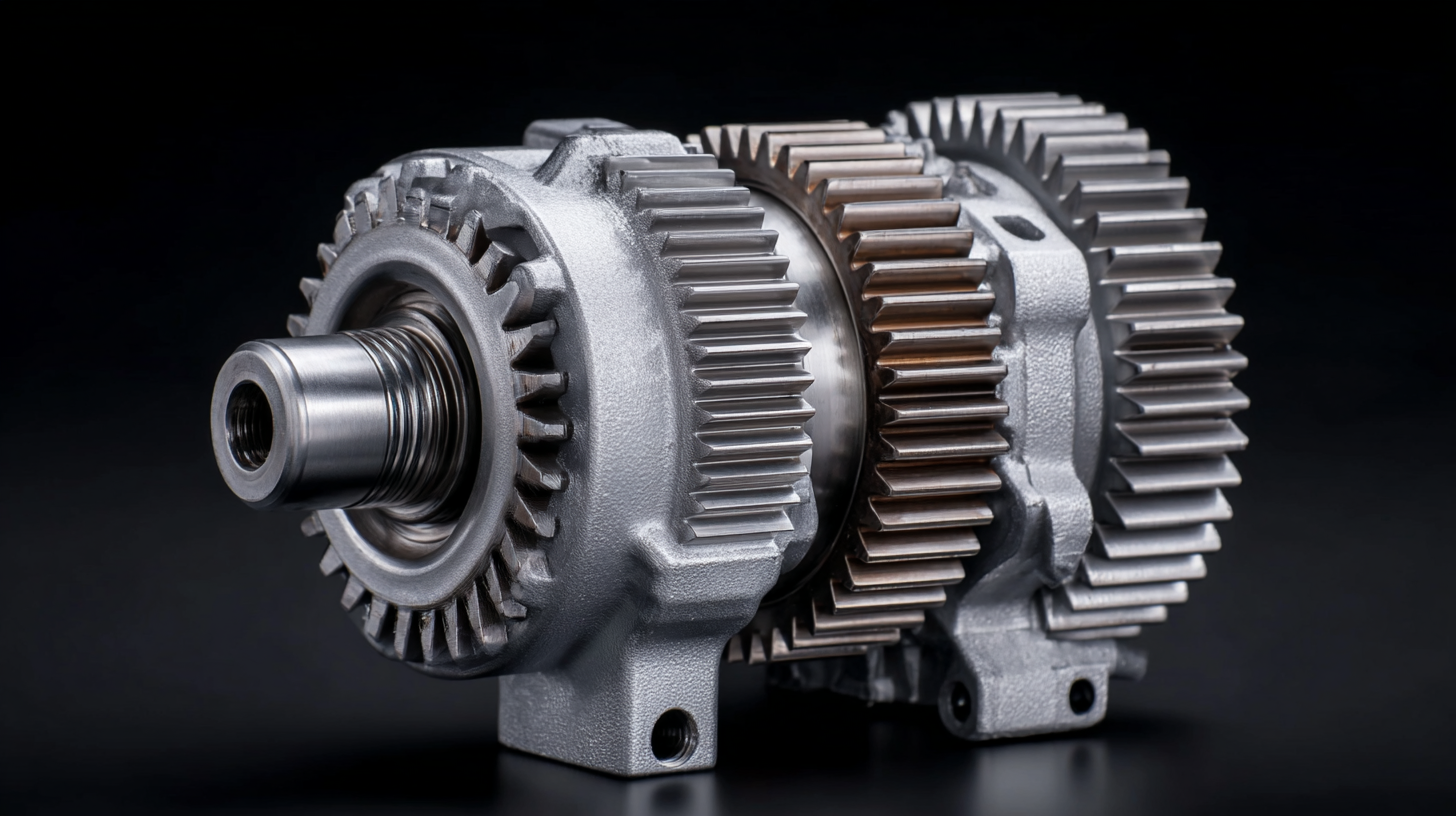

Additionally, it’s essential to consider gear type. For high-torque applications, helical gears are often recommended due to their smooth operation and efficiency.

**Tip:** When in doubt, seek expert advice or perform simulations to better understand how different gearbox configurations will perform in your intended application.

Gearbox Selection Criteria Importance

Key Specifications to Consider When Choosing a Gearmotor for Your Application

When selecting the ideal gearmotor for your application, understanding key specifications is crucial. Pay attention to the torque output; different applications may require varying levels of torque for optimal performance. According to a report by the International Journal of Engineering Research and Applications, gearmotors delivering a torque range between 10Nm to 100Nm are commonly utilized in industrial automation, making them versatile for a variety of tasks.

Tips: Always match the gearmotor's torque with your application's specific requirements to avoid underperformance or mechanical failure.

Another vital specification is the gear ratio, which impacts both speed and torque characteristics. A higher gear ratio generally provides greater torque but at a lower speed, while a lower ratio offers increased speed at the expense of torque. Research by Gear Technology Journal indicates that applications requiring precise movement should consider gear ratios meticulously, as they directly influence operational efficiency and reliability.

Tips: Consider using a gearmotor with adjustable gear ratios for greater flexibility in application settings.

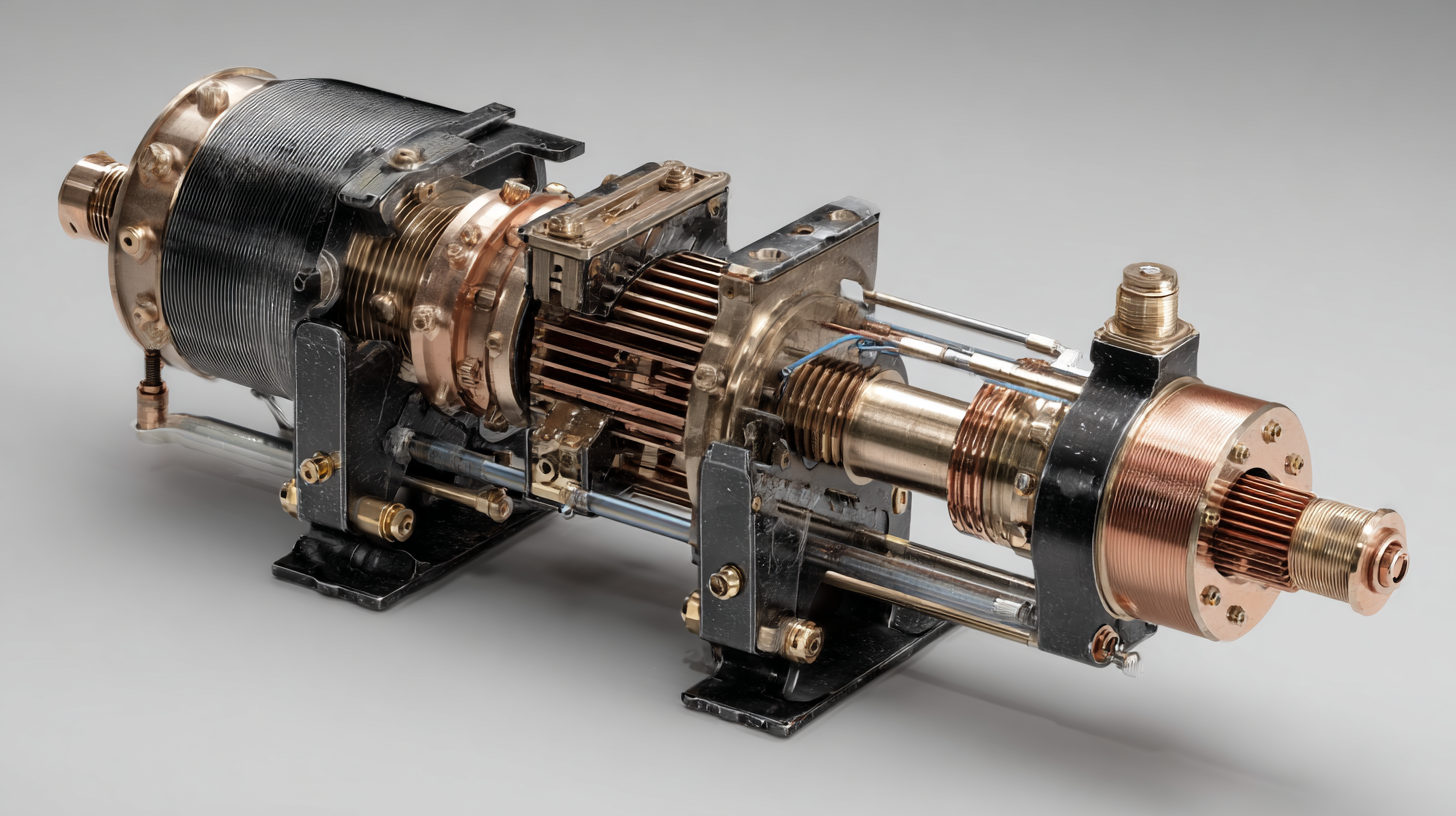

Comparative Analysis of Gearbox Types and Their Efficiency Ratings in Different Industries

When selecting a gearbox, understanding the efficiency ratings of different types can significantly impact operational performance across various industries. Gearboxes, which are integral in converting motor speed and torque, come in various forms, each tailored for specific applications. For instance, spur gearboxes are renowned for their simplicity and high efficiency, making them ideal for automotive and manufacturing applications. In contrast, worm gearboxes, while offering high reduction ratios, exhibit lower efficiency due to increased friction. Therefore, conducting a comparative analysis of these types can help businesses make informed decisions based on their specific operational needs.

In industries such as robotics, aerospace, and energy, the efficiency of the gearbox directly correlates with energy consumption and output performance. Helical gearboxes, for example, are favored in aerospace for their quiet operation and smooth acceleration capabilities, while planetary gearboxes are often employed in robotic applications for their compact design and optimal torque output. By evaluating the efficiency ratings and matching them with the demands of each industry, companies can enhance productivity while minimizing energy costs, ultimately leading to a more sustainable operational framework.

Cost-Benefit Analysis: Investing in Quality Gear Motors vs. Budget Options

When considering the purchase of a gearbox innonomotics gearmotor, it's essential to weigh the cost-benefit analysis of investing in quality gear motors versus opting for budget options. Quality gear motors often offer enhanced durability, efficiency, and better performance over time, which can lead to lower maintenance costs. On the other hand, budget options may appear attractive initially but can incur higher long-term costs due to frequent replacements or inefficiencies.

Tips for making the right choice include evaluating the lifespan and warranty of the gear motor. A longer warranty typically indicates the manufacturer's confidence in the product’s durability. Additionally, consider the operational efficiency; a high-quality gear motor may consume less energy during usage, contributing to lower energy bills and a smaller carbon footprint. As sustainability continues to be a priority across industries, investing in reliable equipment can significantly impact your overall environmental footprint.

Another vital tip is to assess the specific needs of your application. If your operations demand high precision and consistent performance, prioritizing quality is crucial. Conversely, if the application is less demanding, budget options might suffice for short-term projects. Always align your choice with both current and future operational goals.

Ultimate Checklist for Choosing the Best Gearbox Innonomotics Gearmotor for Your Needs

| Criteria |

Quality Gear Motors |

Budget Options |

| Durability |

High (5-10 years) |

Medium (1-3 years) |

| Cost |

$200 - $500 |

$50 - $150 |

| Efficiency |

90% - 95% |

70% - 85% |

| Maintenance Frequency |

Once a year |

Every 6 months |

| Noise Level |

Low (50 dB) |

High (70 dB) |

Real-World Case Studies: Successful Implementations of Innonomotics Gearmotors

Recent advancements in gear motor technology have significantly impacted various industries, particularly in the realm of robotics and automation. For instance, underwater remote-operated vehicles (ROVs) have benefitted from the integration of rugged gearmotors, designed specifically to withstand harsh underwater environments. These gearmotors enhance the efficiency and maneuverability of ROVs, enabling them to perform intricate tasks in underwater exploration and maintenance. According to industry reports, the demand for reliable gear motors in robotics has surged, driven by innovations that require precise control and durability.

Another notable implementation is the integration of specialized gearmotors into robotic arms for lunar exploration missions. These gearmotors are critical for executing complex movements while ensuring the accuracy necessary for scientific experiments on the lunar surface. The ability to seamlessly integrate high-performance gear systems into space applications underscores the versatility and essential role that gearmotors play in modern engineering projects.

Industry insights suggest that as technology evolves, the demand for high-efficiency gearmotors will continue to rise, fostering advancements in diverse fields from underwater engineering to extraterrestrial exploration.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor