How to Choose the Right Neupex Coupling for Your Mechanical Needs

When it comes to ensuring the efficiency and reliability of mechanical systems, choosing the right components is crucial. Among these components, the Neupex Coupling stands out as a flexible solution designed to accommodate various operational demands. Its unique design allows for the connection of rotating shafts, enabling the transmission of torque while compensating for misalignments and vibrations. As industries evolve and technological advancements continue, the importance of selecting the appropriate Neupex Coupling cannot be overstated.

In this guide, we will explore the factors that influence the selection of Neupex Couplings and how they can be tailored to meet specific mechanical needs. By understanding the different types available, their advantages, and the applications they are best suited for, you can make an informed decision that enhances the performance and longevity of your mechanical systems. Whether you are dealing with pump drives, conveyor systems, or other machinery, the right Neupex Coupling will play a pivotal role in optimizing operational efficiency and reducing maintenance costs.

Understanding Neupex Couplings: Types and Functions

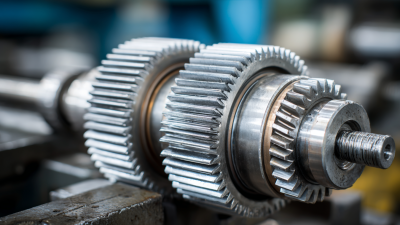

Neupex couplings are essential components in various mechanical systems, designed to transmit torque while accommodating misalignment and vibration. Understanding the different types and functions of these couplings can significantly influence their effective application. Neupex couplings generally come in flexible and rigid designs, each suited for specific purposes. Flexible couplings are ideal for applications where shaft misalignment might occur, allowing for slight angular or parallel discrepancies. This flexibility helps in reducing wear and tear on connected equipment, making them suitable for diverse industries.

In contrast, rigid couplings provide a solid connection between shafts that need to maintain precise alignment. These are predominantly used in applications where high torque and minimal backlash are critical. The choice between flexible and rigid variants depends on the operational requirements, such as load type, speed, and the degree of alignment achievable in a given installation. By assessing these parameters, users can select the most appropriate Neupex coupling to ensure seamless operation and longevity of their mechanical systems.

Key Factors in Selecting the Right Neupex Coupling

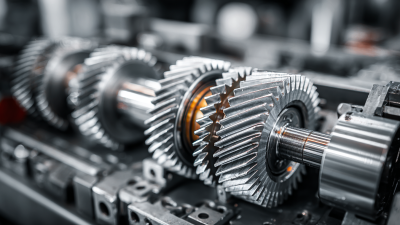

When selecting the right Neupex coupling for your mechanical needs, several key factors should be considered to ensure optimal performance and reliability. First, assess the operational parameters such as torque, speed, and temperature range. Understanding these conditions will help you select a coupling that can handle the specific demands of your application without risking failure or inefficiencies.

Another critical factor is the size and alignment of the equipment being coupled. Proper alignment is essential to minimize wear and extend the lifespan of the coupling. Additionally, consider the environment in which the coupling will operate. Factors such as exposure to chemicals, humidity, or extreme temperatures can influence material selection, ensuring durability and long-term performance.

Tips: Choose a coupling that offers flexibility and vibration dampening, which can reduce stress on connected machinery. Also, ensure easy maintenance and accessibility for inspections, as regular checks can preempt larger issues down the line. Lastly, consult with manufacturer specifications and guidelines to match your needs with the performance capabilities of the coupling effectively.

Assessing Load and Torque Requirements for Your Application

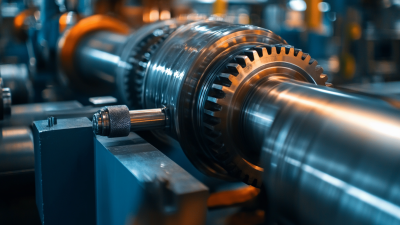

When selecting a Neupex coupling, understanding the load and torque requirements for your specific application is crucial. Load requirements define the maximum force that the coupling will need to transmit during operation. It is essential to consider both static loads, which are present when the equipment is at rest, and dynamic loads, which occur when the machinery is in motion. Evaluating these factors ensures that the coupling can withstand the operational demands without failure.

Torque requirements play a significant role in the selection process as well. Torque refers to the rotational force that the coupling must handle, and it is vital to assess the peak torque conditions that your application will encounter. This includes considering factors such as acceleration and deceleration phases, which can temporarily increase torque levels. By calculating the maximum expected torque and comparing it to the coupling's rated capacity, you can make informed decisions that lead to enhanced performance and longevity of your mechanical setup. Understanding the interplay of load and torque ensures that you choose a coupling that not only meets your application's needs but also operates efficiently and reliably under varying conditions.

Material Compatibility: Choosing the Best Neupex Coupling

When choosing a Neupex coupling, material compatibility is crucial to ensure optimal performance and longevity in various mechanical applications. The first step is to consider the operating environment where the coupling will be used. Different materials react uniquely to factors such as temperature, humidity, and exposure to chemicals. For instance, selecting a coupling made of non-corrosive materials is essential for environments where moisture or aggressive substances are present. Identifying the specific requirements of your application allows for informed material selection that can withstand operational stresses and external conditions.

Furthermore, understanding the materials involved in the connected components is vital. Compatibility extends beyond just the coupling; it involves ensuring that the materials chosen for the coupling complement those of the shafts or other connected elements. For example, using a coupling with a softer material against a harder one can lead to premature wear. Additionally, consider the thermal expansion rates of the materials, as differences can lead to performance issues down the line. Thorough assessment of these factors will help in selecting the right Neupex coupling, ensuring efficiency and reliability in your mechanical systems.

Installation Considerations and Maintenance for Longevity

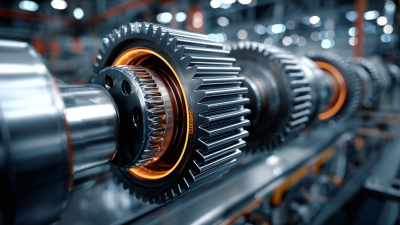

When selecting a Neupex coupling for mechanical applications, it's crucial to consider installation factors and maintenance practices that ensure longevity. Proper alignment during installation is essential. Misalignment can lead to premature wear, increased vibration, and operational inefficiencies. According to industry reports, such as those from the American Gear Manufacturers Association, misalignment can cause a 50% reduction in the lifespan of couplings. Therefore, using alignment tools and thoroughly checking for proper fit before final assembly can significantly enhance durability.

Maintenance plays a key role in extending the life of Neupex couplings. Regular inspection for signs of wear, such as cracks or surface degradation, is vital. A recent study published in the Journal of Mechanical Engineering highlighted that scheduled maintenance can increase coupling life by 30%. Additionally, ensuring that the couplings are kept free from contaminants, such as dust and moisture, can prevent degradation of materials. Implementing a routine maintenance schedule that includes lubrication, when applicable, can further reduce friction and wear, thereby maximizing performance over time.

How to Choose the Right Neupex Coupling for Your Mechanical Needs - Installation Considerations and Maintenance for Longevity

| Coupling Type |

Torque Rating (Nm) |

Max Speed (RPM) |

Material |

Installation Notes |

| Flexible Coupling |

150 |

3000 |

Aluminum |

Ensure proper alignment before installation. |

| Rigid Coupling |

250 |

4500 |

Stainless Steel |

Tighten the screws evenly for optimal performance. |

| Gear Coupling |

350 |

2500 |

Carbon Steel |

Check lubrication before use. |

| Chain Coupling |

200 |

3500 |

Metal Alloy |

Ensure chain tension is proper. |

| Oldham Coupling |

80 |

5000 |

Plastic |

Check for wear on the sliding surfaces. |

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor