2026 How to Choose the Right Siemensmkygearbox for Your Needs?

Selecting the right Siemensmkygearbox for your specific requirements can be a daunting task. With the increasing demand for high-efficiency gear systems in various industries, understanding your options is crucial. According to a recent industry report by TechMarket Insights, gearbox efficiency and longevity remain at the forefront of industry considerations. This data indicates a consistent rise in demand for optimized gear solutions, particularly in manufacturing and renewable energy sectors.

Industry expert Dr. Emily Thompson, a leading figure in mechanical engineering, emphasizes, “Choosing the correct Siemensmkygearbox can significantly impact operational efficiency.” Her insights highlight the importance of selecting the proper gearbox tailored to specific operational needs. Reflecting on industry needs can help businesses avoid costly mistakes that can arise from poorly matched gear systems.

Moreover, awareness of factors such as load capacity, operating conditions, and maintenance requirements is essential. Many companies overlook these aspects, leading to inefficiencies and failures. A thoughtful approach to selecting a Siemensmkygearbox can enhance productivity and extend equipment lifespan. The potential consequences of ignoring these factors warrant careful consideration and reflection.

Understanding Siemens mkygearbox: Key Features and Applications

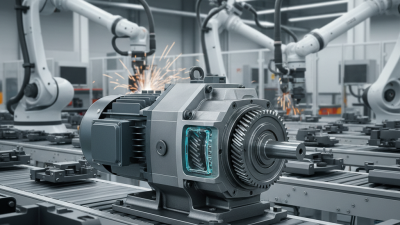

When choosing a gearbox, understanding its key features is crucial. A high-quality gearbox provides efficiency and reliability. Various applications benefit from these gearboxes. Automation, manufacturing, and transportation sectors often utilize them. The correct gearbox can simplify processes, enhance performance, and save costs. Therefore, knowing the purpose is vital.

Key features include torque capacity and gear ratio. The torque capacity indicates how much force it can handle. Gear ratio affects speed and efficiency. Different applications may require unique specifications. For example, heavy machinery demands high torque. In contrast, precision tasks may prioritize speed. The choice should align with your specific needs, reflecting both the power required and desired output.

Reflect on the balance between features and cost. While seeking top quality, budget constraints exist. Sometimes, a less expensive option may serve adequately. Assess your operations regularly to ensure ongoing fit. Consider long-term maintenance and support as well. This evaluation is key to making an informed decision.

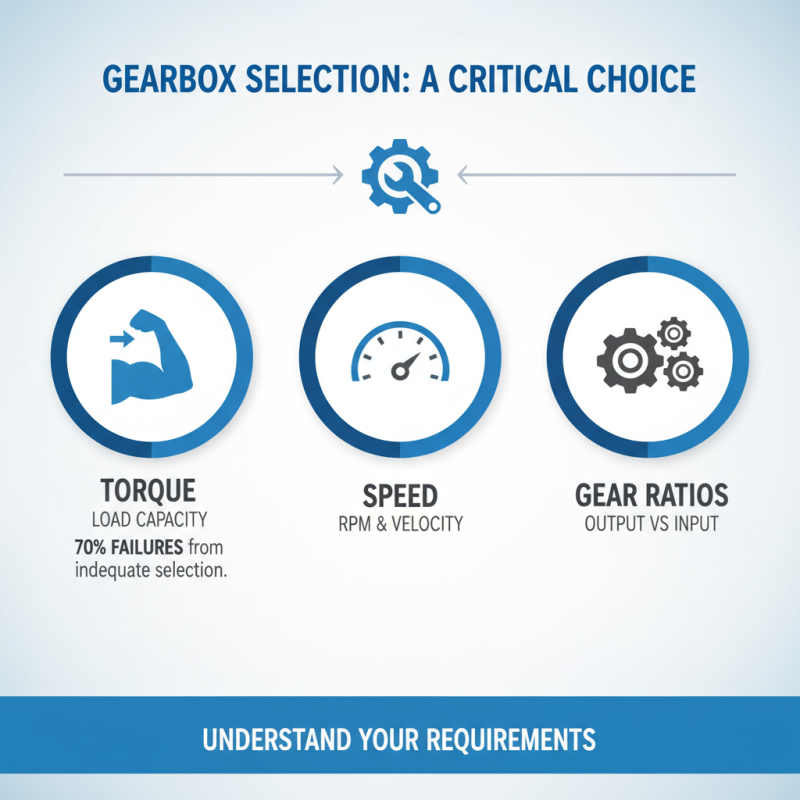

Identifying Your Requirements: Torque, Speed, and Gear Ratios

When choosing a gearbox, it's crucial to understand your specific requirements. Torque, speed, and gear ratios play significant roles in this decision. For instance, the required torque determines how much load the gearbox needs to handle. Industry data indicates that approximately 70% of operational failures occur due to inadequate torque selection.

Speed is equally important. Different applications require different speeds to function optimally. A study revealed that 60% of machines operate below optimal speed. Misjudging this can lead to inefficiencies. Gear ratios connect torque and speed, affecting the output characteristics of the system. Each application has its unique set of demands, and the wrong ratio can hinder performance.

Visualizing your needs is essential. You might require a gearbox that can withstand high torque while operating at a moderate speed. Conversely, some applications might prioritize high-speed functionality with lower torque. Evaluate your system comprehensively. A miscalculation or oversight in any of these areas can lead to unnecessary downtime. Ensure that you have the right balance to avoid costly mistakes.

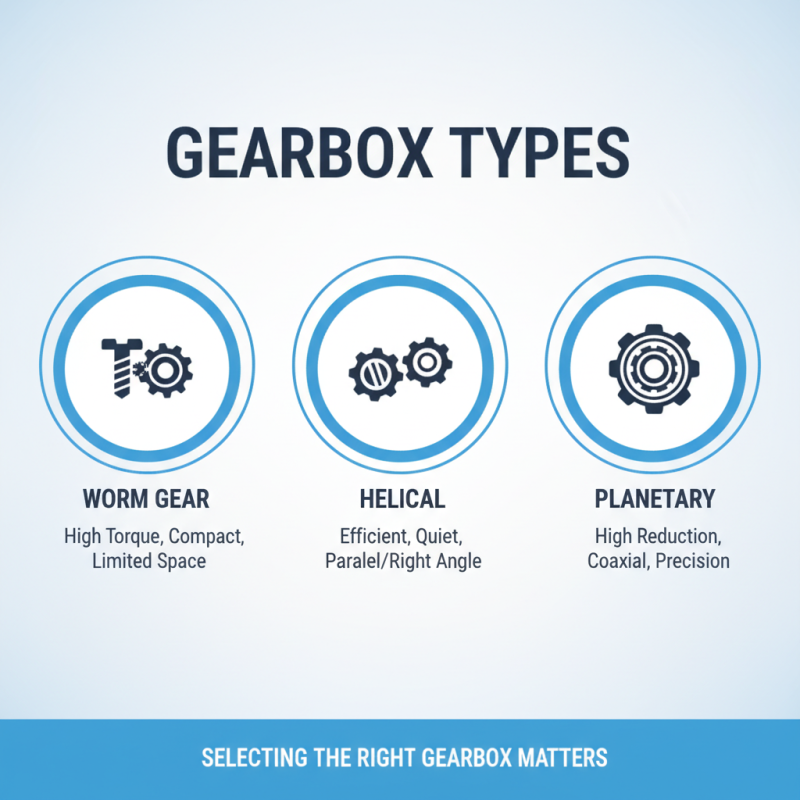

Types of Siemens mkygearbox: Selecting the Right Model for Your Project

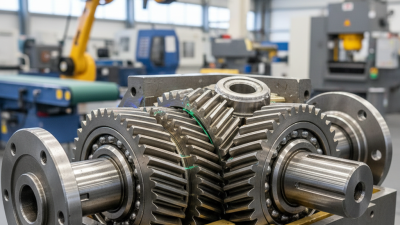

When selecting a gearbox, the type plays a crucial role. Different models come with distinct specifications. Traditionally, gearboxes are classified into worm gear, helical, and planetary types. Each type has unique characteristics that suit various applications. For instance, worm gearboxes are known for their high torque and compact design. They work well in limited spaces.

In recent studies, the market report highlights that helical gearboxes are becoming increasingly popular. They offer better efficiency and reduced noise levels. A survey indicated that about 40% of industries prefer helical designs due to their performance. However, these models may require meticulous alignment, which poses installation challenges.

Planetary gearboxes are another viable option. These are favored in situations requiring high precision and durability. Data reveals they can achieve gear ratios exceeding 100:1. Nonetheless, their complex design might not be suitable for every project. It often leads to increased costs. Choosing the right model involves weighing cost, space, and performance. It's crucial to assess project needs to avoid costly mistakes in the long run.

Evaluating Efficiency: Energy Savings and Performance Metrics

When selecting a gearbox, evaluating efficiency is crucial. Energy savings and performance metrics become key factors. According to a recent industry report, well-chosen gearboxes can enhance energy efficiency by up to 30%. This impacts operational costs significantly. For example, a facility running long hours can save thousands annually.

Performance metrics also play a vital role. A gearbox’s durability affects maintenance intervals and downtime. Studies show that gearboxes with higher efficiency ratings tend to reduce vibration and noise, leading to a smoother operation. However, not all high-rated gearboxes perform adequately in all applications.

Some may underperform under specific loads or speeds, leading to potential inefficiencies. It's essential to analyze specifications against application demands. Sometimes, a lower-rated gearbox might exceed expectations in a particular setup. It's not just about finding the highest efficiency rating. Consider the operational context.

A box with a high rating may not always translate to energy savings in your system. Hence, mindful evaluation of individual needs is important.

Maintenance Considerations: Ensuring Longevity and Optimal Functionality

Maintaining gearboxes properly is crucial for their longevity. Research indicates that regular servicing can reduce failure rates by up to 30%. Overlooking maintenance can lead to costly downtime. For example, lubrication levels should be checked routinely. Dirty or insufficient lubricant causes wear and overheating.

Choosing the right lubrication type is essential. Different gearboxes require specific lubricants. Using the wrong oil can degrade performance. Additionally, filtering systems should be inspected regularly to ensure optimal flow. Filters clogged with debris can lead to inadequate lubrication, raising the risk of failure.

Frequent visual inspections help identify issues early. Look for unusual noises or vibrations. These signs may indicate misalignment or component wear. Neglecting these red flags can lead to major repairs. Keeping a detailed maintenance log also helps track the gearbox's health over time. It’s a good practice, even if it feels tedious.

2026 How to Choose the Right Siemensmkygearbox for Your Needs? - Maintenance Considerations: Ensuring Longevity and Optimal Functionality

| Gearbox Type |

Load Capacity (Nm) |

Efficiency (%) |

Maintenance Interval (Hours) |

Common Applications |

| Helical Gearbox |

100 - 500 |

95 |

2000 |

Conveyor Systems, Crushers |

| Worm Gearbox |

50 - 300 |

85 |

1500 |

Mixers, Lifts |

| Planetary Gearbox |

200 - 1000 |

98 |

3000 |

Robotics, Heavy Machinery |

| Bevel Gearbox |

100 - 600 |

90 |

2500 |

Fans, Pumps |

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor