How to Choose the Right Siemensmkygearbox for Your Industrial Needs to Maximize Efficiency

In the ever-evolving landscape of industrial machinery, the importance of choosing the right gearbox cannot be overstated. According to a recent report by MarketsandMarkets, the global industrial gearbox market is projected to reach $34.4 billion by 2026, growing at a CAGR of 5.1%. Among the various options available, the Siemensmkygearbox stands out due to its innovative design and reliability, which are critical for optimizing operational efficiency and reducing downtime. With industries increasingly focusing on enhancing productivity while minimizing energy consumption, selecting an appropriate gearbox can have significant implications for a company's bottom line.

The Siemensmkygearbox not only offers superior performance but also integrates seamlessly with modern automation systems. A study by TechNavio highlights that advanced gear technologies can lead to efficiency gains of up to 20% in industrial operations. This makes it vital for decision-makers to consider factors such as load capacity, energy efficiency, and maintenance requirements when choosing a gearbox. By understanding these elements, companies can significantly enhance their operational workflows and align with industry standards for sustainability and productivity.

Understanding the Different Siemens mkygearbox Models Available for Industrial Applications

When selecting a Siemens mkygearbox for your industrial applications, it's crucial to understand the various models available and their specific features. Siemens offers a range of mkygearbox configurations, each designed to meet different operational requirements. The key models include the standard mkygearbox, the high-torque variant, and specialized versions for extreme conditions. Each type has its own strengths and is suited for particular industrial settings, from manufacturing to material handling.

The standard mkygearbox is ideal for moderate load applications, providing efficient performance and reliable operation. It features a compact design, making it suitable for installations where space is limited. In contrast, the high-torque model is engineered for heavy-duty operations, delivering increased power capacity and durability. This makes it a preferred choice for industries like mining or construction, where equipment must withstand harsh conditions.

For industries with unique demands, Siemens also offers customizable mkygearbox solutions. These models can be tailored to fit specific project requirements, whether that involves modifications for temperature extremes or adaptations for increased efficiency. Understanding these different mkygearbox models equips businesses to make informed decisions, ensuring optimal performance and greater efficiency in their operations.

Assessing the Critical Factors for Selecting the Right Gearbox Size and Ratio

When selecting a Siemensmky gearbox for industrial applications, understanding the critical factors that influence the ideal size and ratio is essential for maximizing efficiency. According to the American Gear Manufacturers Association (AGMA), proper gearbox selection can improve energy efficiency by up to 15%, significantly impacting operational costs. The demonstrated relationship between gearbox efficiency and energy consumption highlights the necessity of choosing the right specifications tailored to your machinery's requirements.

One of the primary factors to consider is the size of the gearbox, which directly correlates with the load it must handle. Oversized gearboxes can lead to increased material costs and unnecessary weight, while undersized models may result in failures or reduced performance. A study by McKinsey & Company indicates that up to 30% of industrial energy consumption can be attributed to inefficient machinery designs, underscoring the importance of accurate load assessments and size determination based on production demands.

In addition to size, the gear ratio plays a critical role in ensuring optimal performance. A well-calibrated gear ratio enables the motor to operate at its peak efficiency, reducing the risk of overheating and mechanical strain. Research by the International Energy Agency (IEA) shows that optimizing gear ratios can lead to a 25% reduction in energy requirements during peak operational hours. Hence, conducting thorough analyses of torque requirements, speed ratios, and application specifics is fundamental in selecting a Siemensmky gearbox that not only meets but exceeds efficiency targets in industrial settings.

Evaluating Efficiency: How to Analyze Performance Metrics of Siemens mkygearboxes

When selecting the right Siemens mkygearbox for your industrial applications, evaluating efficiency is paramount. Performance metrics play a crucial role in understanding how well a gearbox can fulfill its intended purpose. Start by examining the efficiency rating, typically expressed as a percentage. A higher efficiency rating indicates less energy wasted during operation and translates to lower operational costs over time.

Another important metric is the torque capacity of the gearbox. Understanding the torque requirements of your machinery is essential, as selecting a gearbox that can handle your specific torque demands will significantly enhance performance. Pay close attention to the gearbox's load ratings, as exceeding these can lead to premature wear and failure, ultimately undermining efficiency.

In addition to these technical specifications, consider the gearbox's operating temperature range and lubrication requirements. A mkygearbox operating optimally within its designed temperature range will experience less thermal degradation, preserving efficiency. Similarly, proper lubrication is vital to minimize friction and wear, leading to enhanced performance and prolonged service life. By taking these metrics into account, you can make an informed choice about the best Siemens mkygearbox for your industrial needs.

Maintenance Best Practices for Maximizing the Lifespan of Your Gearbox

When it comes to ensuring the longevity and optimal performance of your Siemensmkygearbox, implementing effective maintenance best practices is key. Regular inspection and monitoring of the gearbox can reveal early signs of wear or potential issues that may cause performance degradation. Keeping an eye on temperature levels, vibration, and lubrication condition can help address problems before they escalate, minimizing downtime and costly repairs.

Lubrication is a critical component in maintaining the functionality of your gearbox. Using the right type and amount of lubricant not only reduces friction but also dissipates heat, preventing overheating. Regularly scheduled oil changes and monitoring of the lubrication system ensure that the gearbox operates smoothly. Make sure to follow the manufacturer’s recommendations for lubrication intervals and types of oils, as this can significantly impact the operational efficiency and lifespan of the gearbox.

Another best practice is to ensure that your gearbox is correctly aligned and mounted. Misalignment can lead to increased stress and premature failure. Using alignment tools during installation and routine checks can aid in maintaining proper positioning. Furthermore, keeping the surrounding area clean and free from dust and contaminants can also help preserve the integrity of the gearbox components. By adhering to these maintenance strategies, you can enhance the reliability and service life of your Siemensmkygearbox, ultimately boosting the efficiency of your industrial operations.

Integrating Siemens mkygearboxes with Other Industrial Equipment for Enhanced Productivity

Integrating Siemens mkygearboxes with other industrial equipment is a critical strategy for enhancing productivity across various sectors. Given their precision engineering and robust performance, Siemens mkygearboxes can significantly optimize the functioning of machines when paired with complementary components. For instance, studies show that using high-efficiency gearboxes can lead to energy savings of up to 15%, making it crucial to combine these gearboxes with energy-efficient motors and application-specific drives to maximize operational performance.

Moreover, the synergy between Siemens mkygearboxes and modern control systems enhances real-time monitoring and automation, resulting in streamlined workflows. According to a report from the International Energy Agency (IEA), industries that implement integrated solutions experience a productivity increase of 20%-30%. By utilizing Siemens mkygearboxes alongside advanced sensors and IoT technology, companies can achieve not only operational efficiency but also improved predictive maintenance, thereby reducing downtime and extending equipment lifespan.

Furthermore, the adaptability of Siemens mkygearboxes allows them to be seamlessly integrated into various industrial applications, from conveyor systems to pumps. A study by the American Gear Manufacturers Association highlights that efficient gearbox integration can lower operational costs by up to 25%. By carefully selecting the right configurations based on specific industrial needs, businesses can leverage the full potential of Siemens mkygearboxes, leading to enhanced productivity and sustained competitive advantage in their respective markets.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

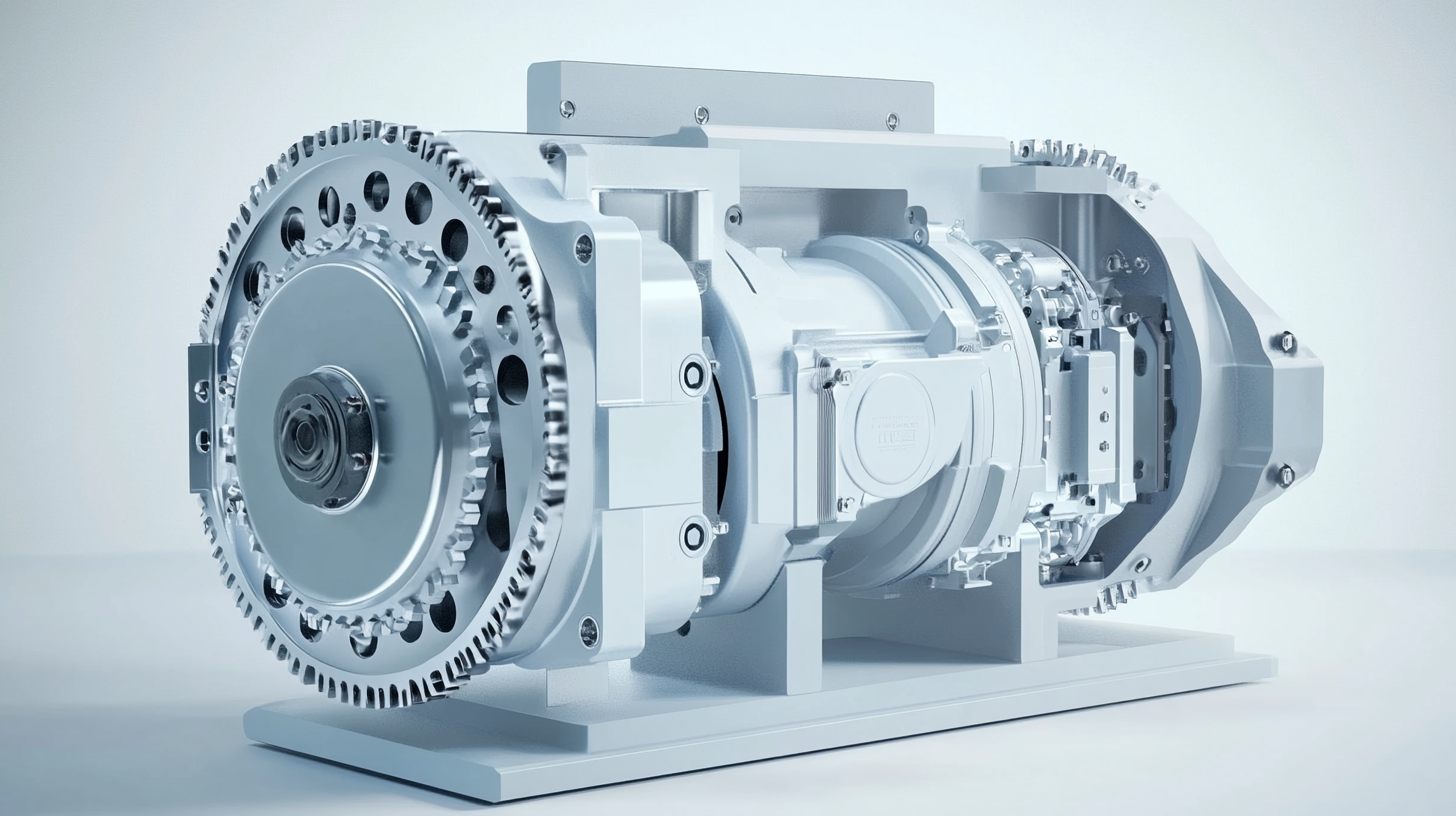

FLENDER Gear Unit  FLENDER Helical Gear Unit

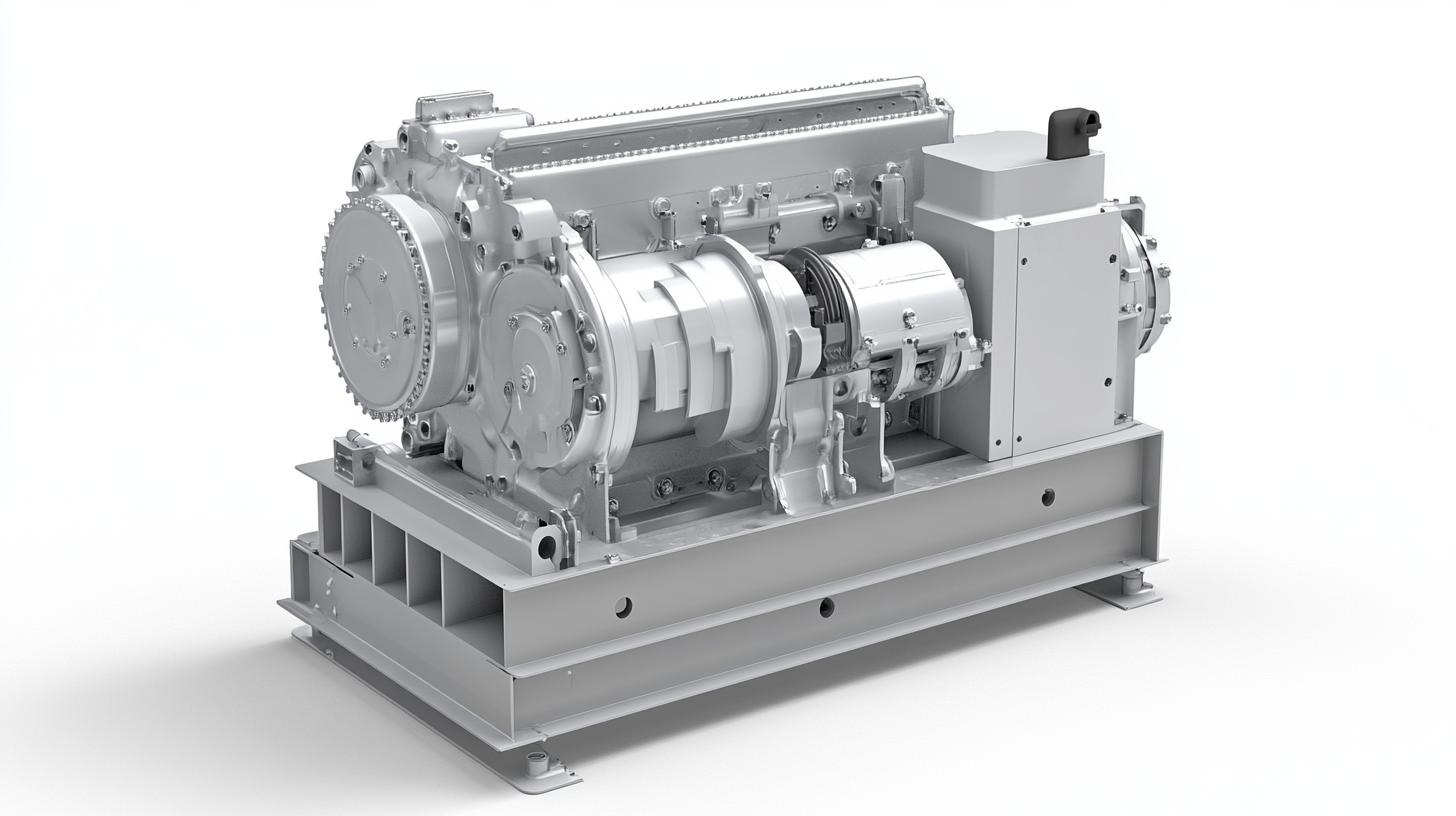

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

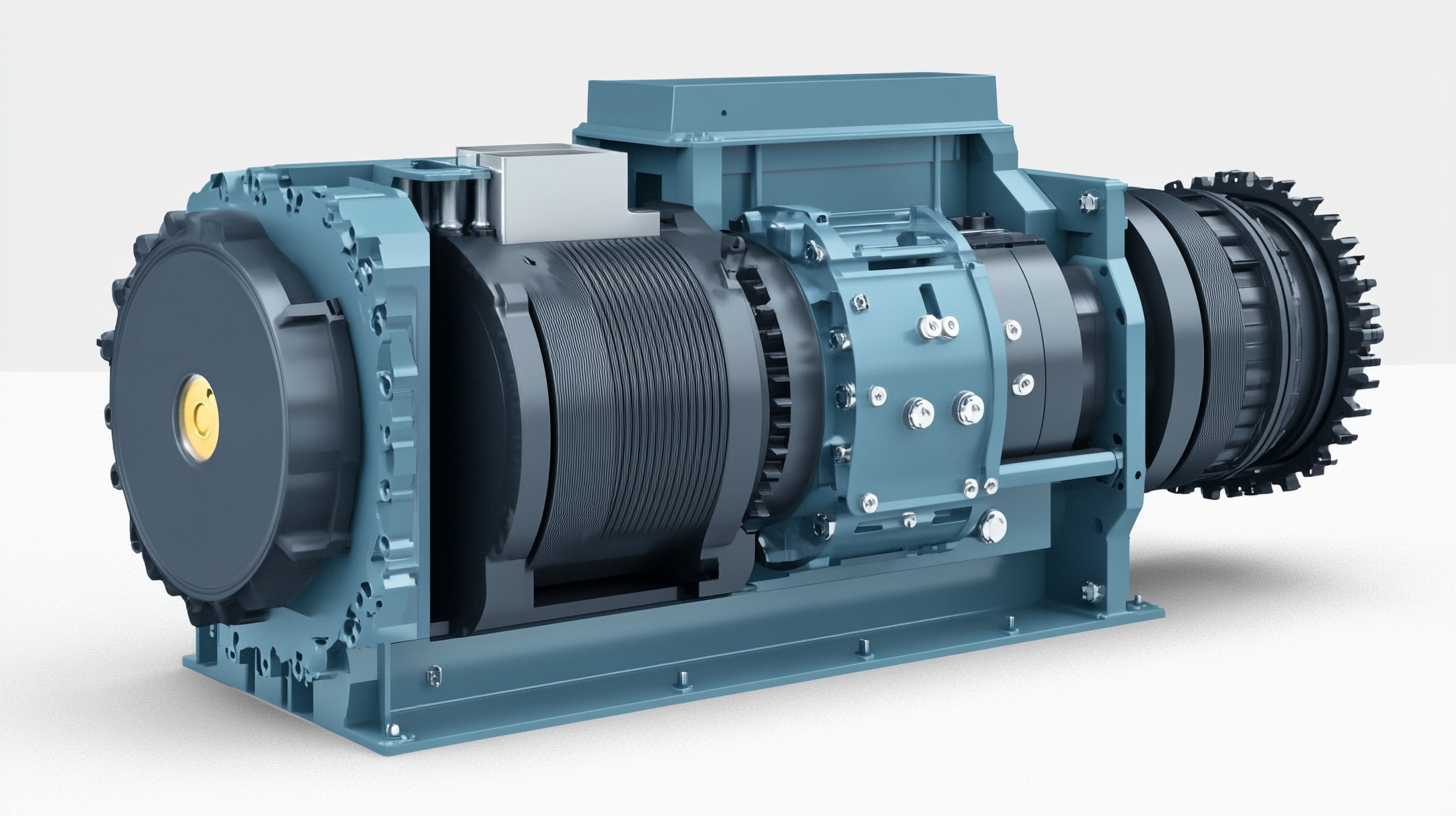

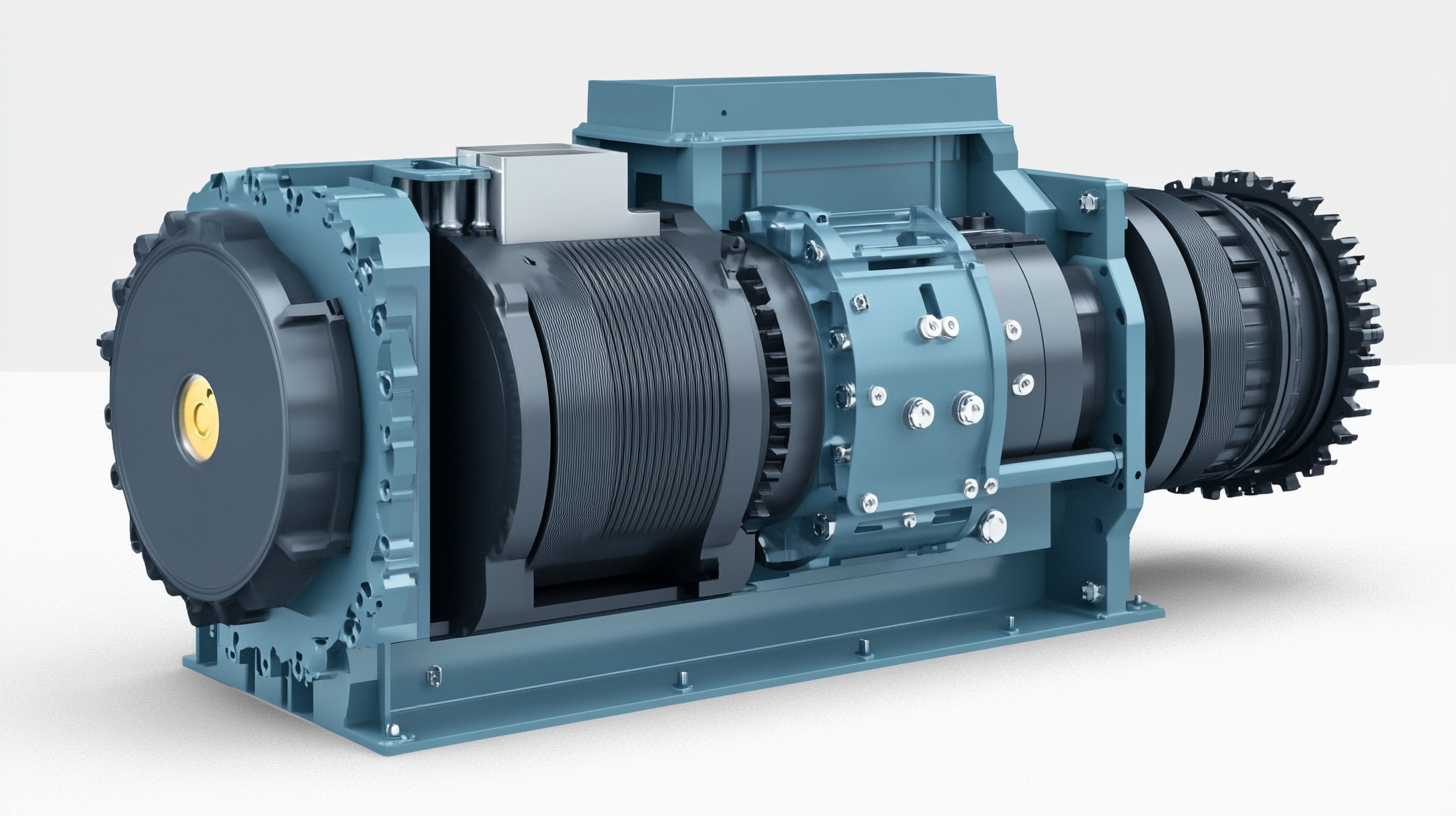

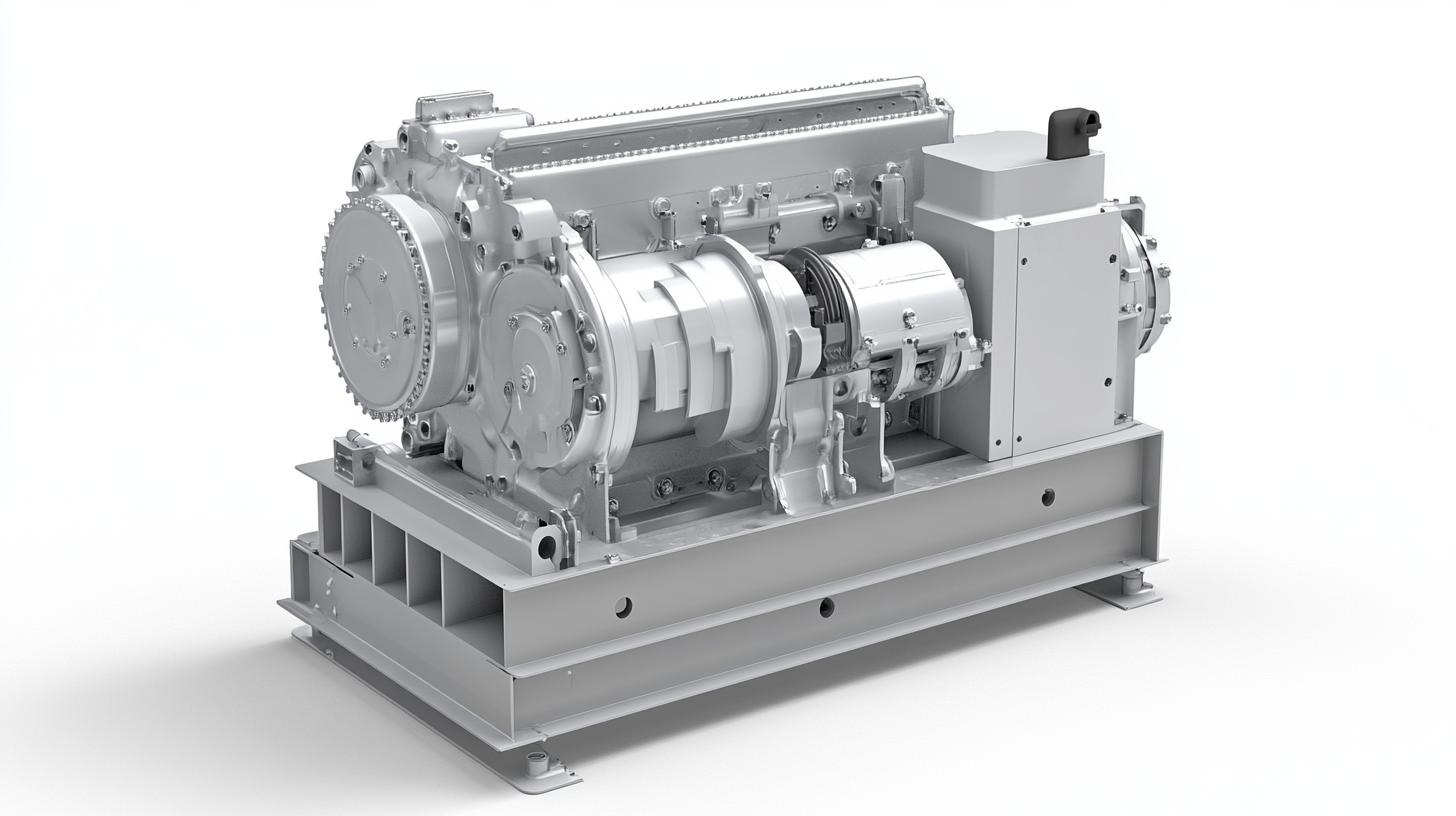

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

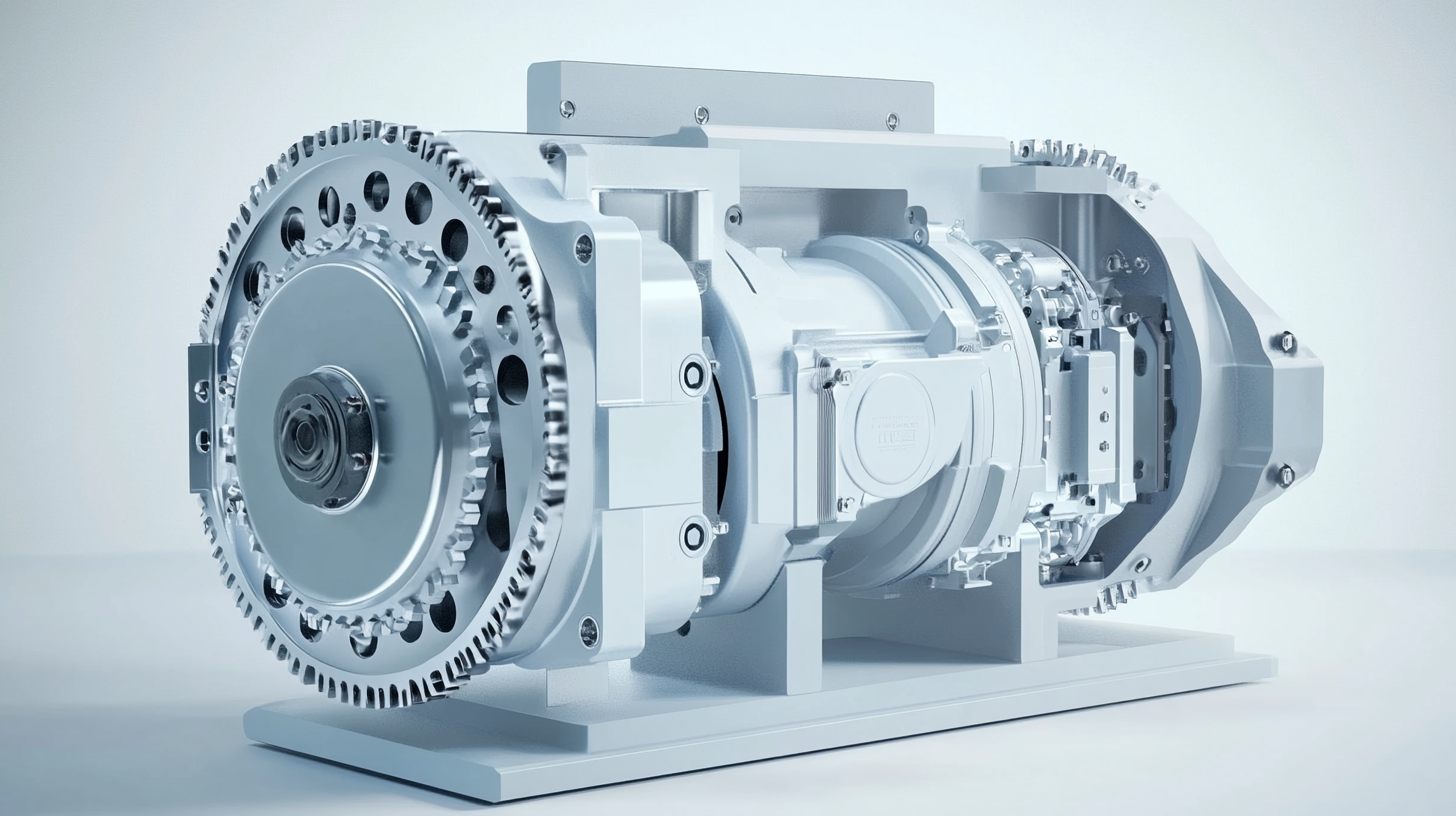

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor