Addressing Common Issues with Gearbox Lenze Gearmotors: Insights and Solutions

The efficiency and reliability of industrial operations heavily depend on the performance of gearmotors, specifically the Gearbox Lenze Gearmotor, which has gained prominence in various sectors due to its robust design and functionality.

According to a recent report from MarketsandMarkets, the global gearmotors market is projected to reach USD 35.5 billion by 2025, showcasing a CAGR of 5.4%.

However, despite their advantages, common issues such as overheating, misalignment, and lubrication failures can hinder their effectiveness.

Understanding these challenges is essential for maintenance teams and engineers alike, as addressing these problems not only prolongs the lifespan of gearbox systems but also optimizes overall performance.

This blog will delve into the most frequent issues associated with Gearbox Lenze Gearmotors, offering insightful analysis and practical solutions to enhance their functionality and reliability in demanding environments.

Understanding the Common Challenges Faced with Lenze Gearmotors

When working with Lenze gearmotors, engineers often encounter common challenges that can hinder performance and efficiency. One primary issue is related to gearmotor specifications, where selecting the wrong torque or speed rating can lead to premature failures. According to industry reports, up to 25% of gearmotor failures stem from mismatched specifications. Understanding nameplate ratings is crucial; they provide essential information regarding load capacities and operational limits. A recent white paper highlighted common pitfalls, emphasizing the importance of interpreting these specifications correctly to avoid costly mistakes in projects.

Another challenge is dealing with the mechanical complexities of gearmotors. For instance, the advent of advanced designs like the innovative hub motor with regenerative braking demonstrates the industry's shift towards more efficient systems. These new technologies are designed to reduce weight and increase performance, yet they also introduce unique integration challenges. As engineers look to incorporate such solutions into their designs, they must consider factors such as compatibility and installation requirements, as the interplay between various components can significantly impact overall performance and longevity of gearmotors. Thus, addressing these issues proactively can lead to improved reliability and efficiency in applications relying on gearmotors.

Essential Diagnostic Tools for Troubleshooting Lenze Gearbox Issues

When troubleshooting common issues with Lenze gearmotors, having the right diagnostic tools can significantly streamline the process. Essential tools like vibration analyzers and thermal cameras enable technicians to identify problems early, reducing downtime and repair costs. For instance, implementing time-frequency analysis methods can reveal underlying issues that may not be immediately apparent, helping to pinpoint faults with precision.

Tips for effective diagnosis include regularly monitoring operational data, which can highlight anomalies in performance before they escalate into serious problems. Additionally, consider investing in multi-dimensional attention denoising convolution techniques, which have been shown to enhance fault diagnosis in gearbox applications. This innovative approach can process large amounts of data and isolate defects more effectively, ensuring a more reliable analysis of gearmotors.

Moreover, keeping records of past repairs and maintenance can provide valuable insights into recurring issues, making future diagnostics faster and more informed. By leveraging these diagnostic tools and techniques, users can enhance the reliability and performance of Lenze gearmotors, minimizing the impact of gearbox-related problems on overall operations.

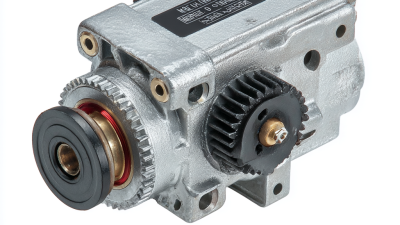

Common Issues with Gearbox Lenze Gearmotors

Proven Techniques to Extend the Lifespan of Lenze Gearmotors

When it comes to extending the lifespan of Lenze gearmotors, industry insights emphasize the importance of preventive maintenance and optimal operating conditions. According to a report by the Machinery Maintenance Institute, regular inspections and servicing can increase the operational lifespan of gearmotors by up to 50%. This not only reduces downtime but also enhances overall system reliability.

Key practices include monitoring lubricant quality, ensuring proper alignment, and maintaining clean operating environments.

Another crucial aspect is adhering to the recommended load specifications. Research from the Gearbox Manufacturers Association indicates that overloading gearmotors can lead to premature failure and costly repairs, potentially reducing life by 30% or more. Implementing load monitoring systems can help operators avoid excessive strain on their equipment.

Additionally, utilizing thermal imaging technology to regularly check for overheating can provide an early warning for potential failures, reinforcing the long-term health of Lenze gearmotors.

By incorporating these proven techniques and insights, manufacturers can significantly enhance the durability and efficiency of their gearmotors.

Key Maintenance Practices to Optimize Gearbox Performance

To ensure optimal performance of Lenze gearmotors, it’s crucial to adopt key maintenance practices that address common issues associated with gearboxes.

Regular inspections can significantly reduce unexpected downtime; a study by the National Association of Fleet Administrators indicates that regular maintenance can decrease failure rates by up to 30%.

Monitoring gear oil levels and replacing them at appropriate intervals protects the gears from wear and tear, helping to maintain operational efficiency.

Tips: Always check for unusual noises or vibrations during operation; these could signal alignment issues or wear.

Keep an eye on the operational temperature, since many manufacturers, including Lenze, recommend specific temperature ranges for optimal performance.

Additionally, maintaining cleanliness around the gearbox area prevents dust and debris from entering, which can cause premature damage.

According to the Machinery Maintenance Report, even a small amount of contamination can reduce a gearbox's lifespan by 50%.

Regularly tracking performance metrics can also help identify trends and pinpoint potential issues before they escalate.

Innovative Solutions for Reducing Gearmotor Downtime and Failures

In the world of automation, gearbox Lenze gearmotors are recognized for their reliability and performance. However, like any mechanical component, they can experience downtime and failures, which disrupt productivity and increase operational costs. Addressing these challenges requires innovative solutions that not only mitigate the risk of breakdowns but also enhance the overall efficiency of the system.

One effective approach to reduce gearmotor downtime is the implementation of predictive maintenance strategies. By utilizing advanced monitoring technologies, operators can collect real-time data on gearmotor performance. Analyzing this data allows for the early detection of potential issues before they escalate into serious failures. Additionally, regular maintenance schedules that include lubrication checks, inspection of seals, and gear alignment adjustments can significantly prolong the lifespan of gearmotors and ensure smooth operation.

Another solution lies in the selection of high-quality replacement parts and the adoption of modular designs. Utilizing superior materials for gearbox components can diminish wear and tear while enhancing durability. Furthermore, modular designs simplify the process of upgrades and repairs, enabling swift replacements and reducing the time the machinery is out of service. By investing in these innovative strategies, businesses can effectively address common gearbox issues, ensuring that their operations run smoothly and efficiently.

Addressing Common Issues with Gearbox Lenze Gearmotors: Insights and Solutions

| Issue |

Possible Causes |

Innovative Solutions |

Downtime Reduction (%) |

| Overheating |

Improper lubrication, excessive load |

Implement thermal management systems |

30% |

| Vibration |

Misalignment, imbalance |

Use precision alignment tools |

40% |

| Oil Leaks |

Worn seals, damaged components |

Routine seal checks and replacements |

20% |

| Gear Wear |

Inadequate lubrication, material fatigue |

Adopt better lubrication technology |

25% |

| Electrical Failures |

Voltage spikes, insulation failure |

Install surge protectors and regular testing |

35% |

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor