Understanding the Differences Between Bucket Elevator Gearboxes for Optimal Performance

In the material handling industry, the choice of equipment can significantly influence operational efficiency and productivity. Among the various components, the Bucket Elevator Gearbox plays a crucial role in determining the overall performance of bulk material conveyance systems. According to a report by Grand View Research, the global market for bucket elevators is anticipated to reach $2.5 billion by 2026, driven by the increasing demand for automated solutions in industries such as agriculture, mining, and construction. Understanding the differences between various bucket elevator gearboxes is essential for optimizing their performance and ensuring a long service life. This ultimate guide delves into the critical factors to consider when selecting a gearbox, including design specifications, operational efficiency, and maintenance requirements, empowering businesses to make informed decisions that contribute to their bottom line.

Types of Bucket Elevator Gearboxes: An Overview of Options

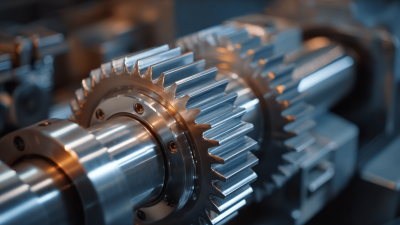

When selecting a bucket elevator gearbox, understanding the various types available is crucial for achieving optimal performance. The most common options include helical gearboxes, worm gearboxes, and planetary gearboxes.

Helical gearboxes are known for their efficiency and durability, making them an excellent choice for high-speed applications. Worm gearboxes, on the other hand, provide high torque and compact design, suitable for situations where space is limited. Lastly, planetary gearboxes offer a remarkable power-to-weight ratio and exceptional load distribution, ideal for heavy-duty operations.

Tip: Consider the operating environment when choosing a gearbox type. For instance, if your bucket elevator operates in a high-temperature or corrosive environment, you might want to explore gearboxes with materials and coatings that can withstand those conditions.

Additionally, maintenance requirements should also factor into your decision. Helical gearboxes typically require regular oil changes, while worm gearboxes may need less frequent servicing. Understanding the maintenance commitments for each type can help prevent unexpected downtime and costly repairs.

Tip: Always consult with your gearbox supplier to understand the specific maintenance needs of your chosen model. Regular maintenance checks can significantly extend the lifespan of your gearbox and ensure smooth operation.

Key Performance Metrics in Selecting Bucket Elevator Gearboxes

When selecting bucket elevator gearboxes, understanding key performance metrics is crucial for ensuring optimal operational efficiency. The performance metrics include torque capacity, gear ratio, efficiency, and durability. Torque capacity determines how much weight the gearbox can handle, which is vital for transporting bulk materials. A higher gear ratio allows for better control over the speed and torque of the elevator, making it easier to adapt to varying operational demands.

When selecting bucket elevator gearboxes, understanding key performance metrics is crucial for ensuring optimal operational efficiency. The performance metrics include torque capacity, gear ratio, efficiency, and durability. Torque capacity determines how much weight the gearbox can handle, which is vital for transporting bulk materials. A higher gear ratio allows for better control over the speed and torque of the elevator, making it easier to adapt to varying operational demands.

Additionally, efficiency plays a significant role in overall performance, as more efficient gearboxes reduce energy consumption and operational costs. Durability is another critical factor; gearboxes that can withstand harsh environmental conditions and heavy workloads will contribute to lower maintenance costs and longer service life. Evaluating these metrics helps in making informed decisions, ensuring that the selected gearbox meets the specific needs of the operation while remaining cost-effective, offering optimal performance even when working within budget constraints.

Comparative Analysis of Gearbox Types for Different Applications

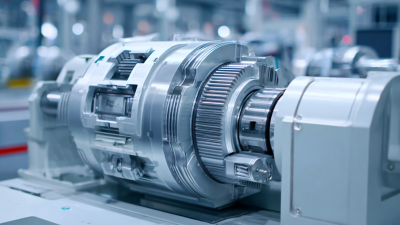

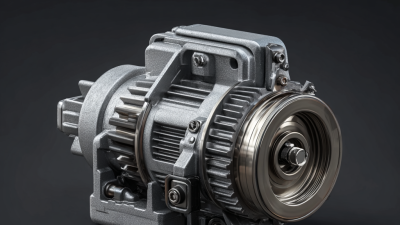

When it comes to bucket elevators, the choice of gearbox can significantly impact performance and efficiency. Different applications require distinct gearbox characteristics to handle varying loads, speeds, and operational conditions. For instance, planetary gearboxes are highly favored in heavy-duty applications due to their compact design and high torque capabilities, making them ideal for transporting bulk materials in challenging environments.

On the other hand, helical gearboxes are often used in lighter applications where smooth operation and energy efficiency are priorities. These gearboxes reduce noise and vibrations, which is crucial in settings where maintaining a quiet atmosphere is necessary, such as food handling facilities. Additionally, the configuration of the bucket elevator itself—whether it’s for vertical or inclined transport—can dictate the suitable gearbox type, as different designs can cater to specific operational demands, influencing both reliability and lifespan.

Understanding the Differences Between Bucket Elevator Gearboxes

This chart compares different types of gearboxes used in bucket elevators based on their efficiency, torque output, and suitability for various applications.

Maintenance Considerations for Various Bucket Elevator Gearboxes

When it comes to maintaining bucket elevator gearboxes, understanding the differences in design and function is crucial for ensuring optimal performance. Many systems utilize a drive shaft to transfer torque from the gearbox output to the bucket drum rotation motor, which plays a vital role in the efficiency of material handling. The gearbox types may vary in efficiency ratings, typically ranging from 80% to over 95%, depending on the construction and lubricant used—factors that directly affect overall energy consumption and operational costs.

Regular maintenance is essential to extend the lifespan of these gearboxes and to prevent unexpected downtime. For instance, it is recommended that lubrication intervals are adhered to based on both usage and environmental factors; gearboxes in dusty environments may require more frequent inspections. Data from industry reports suggest that a proactive maintenance schedule can improve gearbox reliability by up to 30%, leading to significant savings in repair costs and downtime. Implementing condition monitoring practices can further enhance maintenance strategies, allowing operators to identify potential issues before they escalate and ensuring the consistent operation of bucket elevators.

Impact of Gearbox Selection on Overall System Efficiency and Reliability

The selection of the right gearbox for a bucket elevator is crucial to ensuring optimal performance and enhancing system efficiency. Different types of gearboxes offer varying torque capacities, speed ratios, and power transmission methods, all of which directly impact how effectively the elevator operates. A well-chosen gearbox can minimize energy losses, reduce wear and tear on components, and allow for smoother operation, which ultimately leads to increased productivity.

Moreover, reliability is a key factor influenced by gearbox selection. Choosing a gearbox that is specifically designed for the unique demands of the application not only improves performance but also prolongs the lifespan of the system. Gearboxes built with higher quality materials and robust engineering standards can withstand the stresses of heavy-duty operations, preventing unexpected downtimes and costly repairs. By closely analyzing the operational requirements and matching them with the characteristics of various gearboxes, system operators can enhance not only the efficiency but also the overall reliability of their bucket elevators.

Understanding the Differences Between Bucket Elevator Gearboxes for Optimal Performance

| Gearbox Type |

Efficiency (%) |

Load Capacity (kg) |

Maintenance Interval (months) |

Average Lifetime (years) |

| Helical Gearbox |

92 |

1500 |

6 |

15 |

| Bevel Gearbox |

90 |

1200 |

8 |

12 |

| Planetary Gearbox |

95 |

2000 |

12 |

20 |

| Worm Gearbox |

87 |

800 |

10 |

8 |

| Spur Gearbox |

88 |

1000 |

5 |

10 |

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor

When selecting bucket elevator gearboxes, understanding key performance metrics is crucial for ensuring optimal operational efficiency. The performance metrics include torque capacity, gear ratio, efficiency, and durability.

When selecting bucket elevator gearboxes, understanding key performance metrics is crucial for ensuring optimal operational efficiency. The performance metrics include torque capacity, gear ratio, efficiency, and durability.