Comprehensive Guide to Choosing the Right Low Voltage Motor for Your Industrial Needs

In today's rapidly evolving industrial landscape, selecting the right

low voltage motor is crucial for enhancing

operational efficiency and ensuring reliability in various applications. With an

abundance of options available, choosing the ideal low voltage motor can be

overwhelming. This comprehensive guide aims to provide you with top strategies

for navigating the complexities of motor selection, addressing essential factors

such as power requirements,

efficiency ratings, and

environmental considerations. Whether you're seeking to optimize performance in

manufacturing processes or improve energy consumption in your facility,

understanding the critical elements of low voltage motors will empower you to

make informed decisions that meet your specific industrial needs.

Join us as we explore key insights and practical tips to streamline your selection

process and ultimately drive productivity

in your operations.

Understanding Low Voltage Motors: Key Characteristics and Benefits

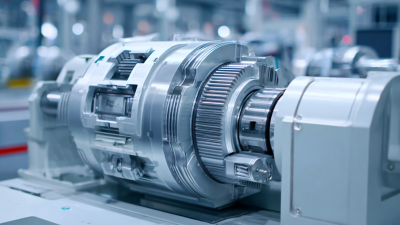

When selecting a low voltage motor for industrial applications, understanding its key characteristics and benefits is crucial. Low voltage motors are designed to operate within a voltage range typically below 1000 volts, making them suitable for various applications. One of the primary advantages is their ability to enhance energy efficiency, which can significantly reduce operational costs. Additionally, these motors offer a compact design, allowing for installation in space-constrained environments while maintaining high performance levels.

Another important characteristic of low voltage motors is their versatility. They are available in different types, such as asynchronous and synchronous motors, each catering to specific industrial applications. Their robust construction ensures durability and reliability, making them ideal for harsh operating conditions. Furthermore, low voltage motors often come with built-in protection features, such as thermal overload protection and IP ratings, which safeguard against dust and moisture ingress. Understanding these aspects will empower decision-makers to choose the right motor that aligns with their operational needs and efficiency goals.

Factors to Consider When Selecting the Ideal Low Voltage Motor

When selecting the ideal low voltage motor for your industrial needs, several important factors must be considered to ensure optimal performance and efficiency. First and foremost, you need to assess the specific application requirements such as load characteristics, operating environment, and the duty cycle of the motor. Understanding whether the motor will be used for continuous or intermittent duty can significantly influence your choice, as different motors are designed to handle distinct operational stresses.

Another crucial element to consider is the motor’s efficiency and energy consumption. With rising energy costs and an increasing emphasis on sustainability, selecting a motor that offers high efficiency can lead to substantial long-term savings. Additionally, evaluating the motor's compatibility with existing systems, like control methods and electrical infrastructure, is essential for seamless integration. Factors such as maintenance needs, availability of spare parts, and technical support also play a vital role in the long-term reliability and performance of the motor. By carefully considering these factors, you can make an informed decision that meets your industrial requirements.

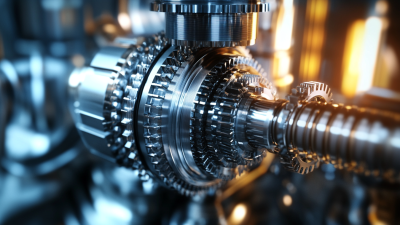

Comparing Different Types of Low Voltage Motors for Industrial Applications

When selecting the right low voltage motor for industrial applications, it's essential to understand the various types available and their unique characteristics. Low voltage motors typically include AC motors, DC motors, and smart motors, each designed to meet specific operational needs. AC motors are well-regarded for their durability and efficiency, making them suitable for a wide range of applications. In contrast, DC motors provide better speed control and torque, making them ideal for situations requiring precise motion management. Smart motors, equipped with advanced features and communication capabilities, are increasingly popular due to their ability to optimize energy consumption and enhance automation processes.

The decision between these motor types depends largely on the specific requirements of the industrial application. For instance, industries focusing on energy efficiency may benefit from smart motors that integrate with automated systems and provide real-time data. Furthermore, the compatibility of these motors with control devices like variable speed drives plays a critical role in their operation. Each motor type presents distinct advantages and potential drawbacks, emphasizing the need for a comprehensive understanding of application requirements to ensure optimal performance and longevity.

Comprehensive Guide to Choosing the Right Low Voltage Motor for Your Industrial Needs

| Motor Type |

Efficiency (%) |

Power Range (kW) |

Application |

Starting Method |

| Induction Motor |

85 - 95 |

0.25 - 500 |

Pumps, Fans, Compressors |

Direct-On-Line (DOL) |

| Brushless DC Motor |

90 - 98 |

0.1 - 15 |

Robotics, Electric Vehicles |

Electronic Speed Control |

| Synchronous Motor |

90 - 95 |

1 - 500 |

Cranes, Elevators |

Variable Frequency Drive (VFD) |

| Stepper Motor |

70 - 90 |

0.01 - 5 |

3D Printers, CNC Machines |

Pulse Control |

| Single Phase Motor |

70 - 85 |

0.1 - 5 |

Fans, Small Appliances |

Capacitance Start |

Maintenance Tips to Ensure Longevity and Efficiency of Your Low Voltage Motor

When it comes to low voltage motors, ensuring their longevity and efficiency is paramount for industrial operations. Regular maintenance not only prolongs the life of these crucial components but also enhances overall performance. One effective tip is to establish a scheduled maintenance program that includes routine inspections and timely replacements of worn parts. Regularly checking motor connections and ensuring they are secure can prevent overheating and energy loss, thus improving efficiency.

Another essential practice is to keep the motor clean and free from debris. Dust and grime can significantly hinder performance, so implementing a cleaning routine that involves both the motor and its surrounding environment is beneficial. Additionally, monitoring the operating conditions, such as temperature and humidity, can help identify potential issues before they escalate. Implementing these strategies can lead to a more reliable operation and reduced downtime, ensuring your low voltage motors continue to perform optimally in your industrial setting.

Low Voltage Motor Efficiency Comparison

This bar chart compares the efficiency of different low voltage motors used in industrial applications. Selecting a motor with higher efficiency can lead to improved performance and reduced energy costs over time.

Future Trends in Low Voltage Motor Technology and Innovation

As industries evolve, the demand for low voltage motors is poised for significant growth, driven by technological advancements and a shift towards energy efficiency. According to a recent report by MarketsandMarkets, the low voltage motor market is projected to reach USD 42 billion by 2026, growing at a CAGR of 6.5% from 2021. This growth can be attributed to the increasing adoption of automation in manufacturing processes and the rising focus on reducing operational costs through energy-efficient solutions.

In addition to efficiency, the future of low voltage motor technology is leaning heavily towards digitalization and smart features. The integration of the Internet of Things (IoT) into motor systems is expected to facilitate real-time monitoring and enhanced performance optimization. A study by Grand View Research highlights that the adoption of smart motors could save up to 30% in energy consumption, presenting an attractive proposition for industries aiming to meet sustainability goals. Furthermore, innovations in materials and designs are enabling manufacturers to produce lighter, more compact motors that maintain high performance, thus reshaping the landscape of industrial applications for years to come.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor