Exploring the Innovative Benefits of Sewmkygearbox in Modern Machinery

In recent years, the machinery industry has witnessed a significant transformation driven by advancements in technology and innovation. Among these innovations, the Sewmkygearbox has emerged as a key component, enhancing operational efficiency and reliability in various applications. According to a report by Grand View Research, the global gear market is expected to reach USD 250 billion by 2025, with gearboxes accounting for a substantial share of this growth. The Sewmkygearbox stands out due to its unique design and superior performance, which contributes to reduced energy consumption and minimized downtime.

As businesses strive to optimize performance and cut operational costs, understanding how to integrate and leverage the Sewmkygearbox in modern machinery becomes crucial. This article delves into the myriad benefits offered by the Sewmkygearbox and provides practical insights into its application in today's competitive landscape.

As businesses strive to optimize performance and cut operational costs, understanding how to integrate and leverage the Sewmkygearbox in modern machinery becomes crucial. This article delves into the myriad benefits offered by the Sewmkygearbox and provides practical insights into its application in today's competitive landscape.

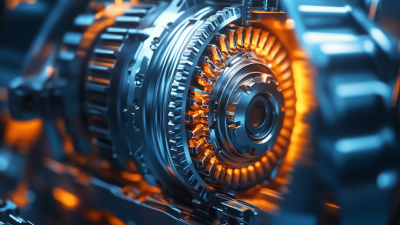

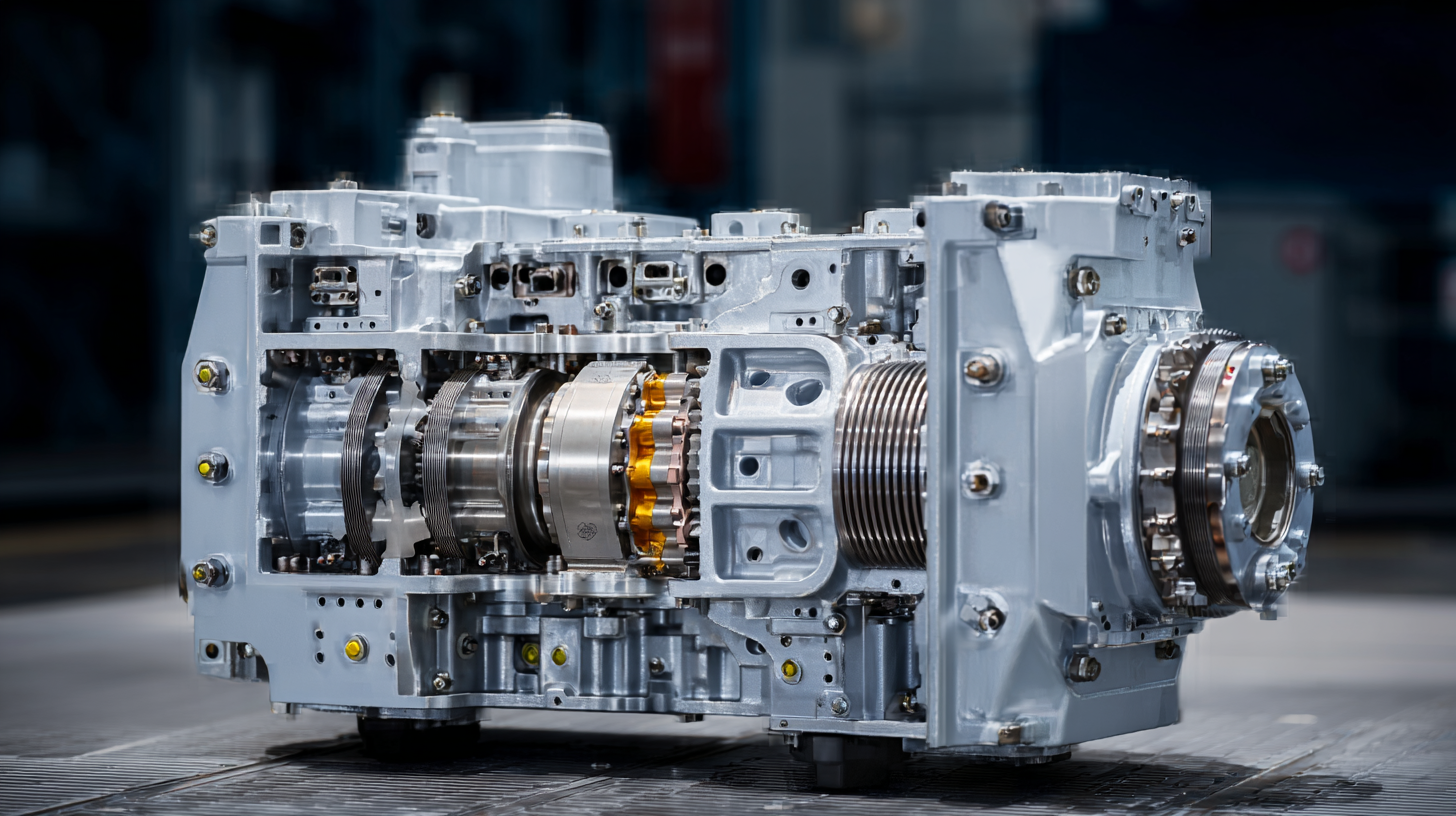

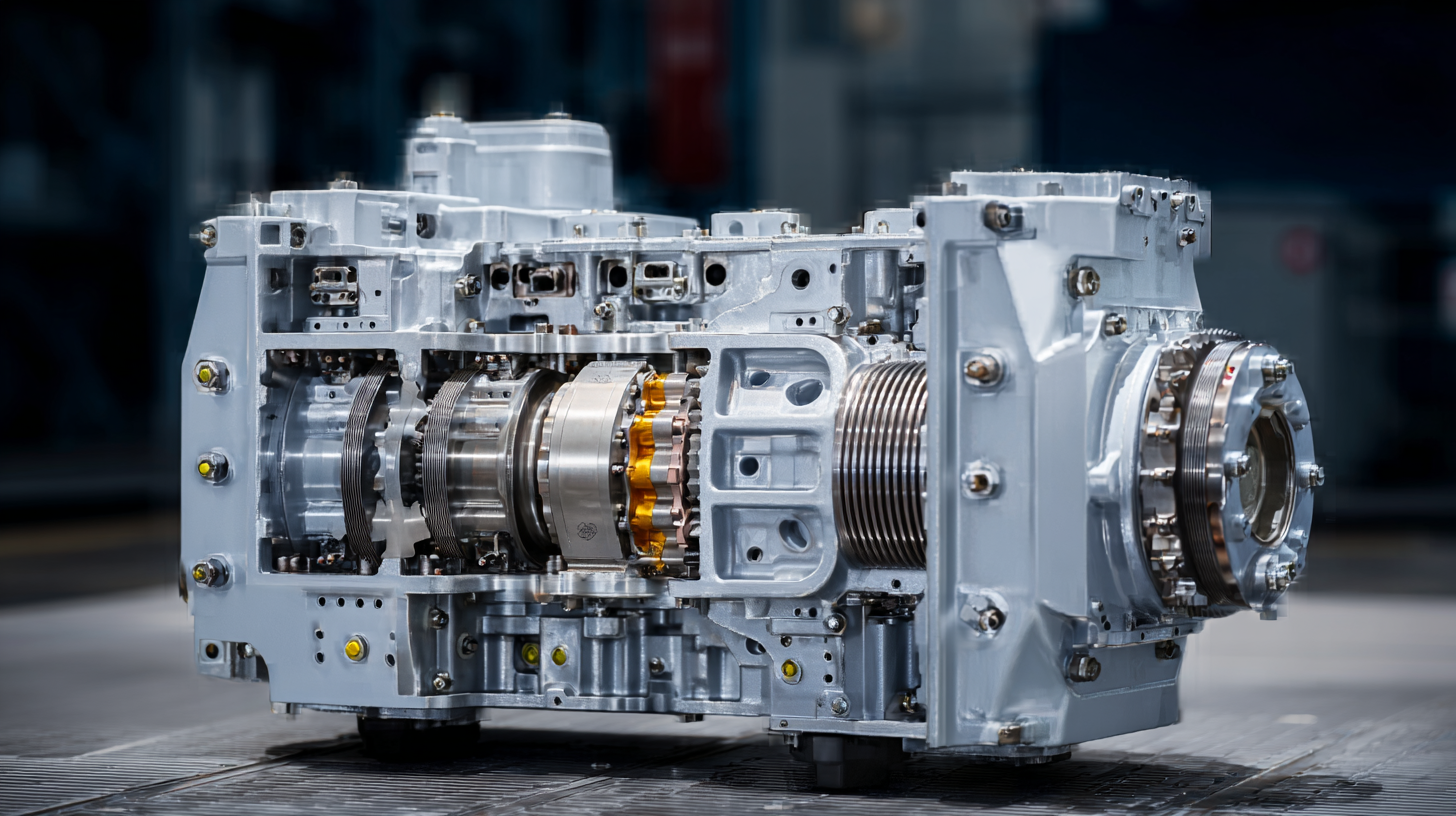

The Revolutionary Design Features of Sewmkygearbox

The Sewmkygearbox stands out in modern machinery due to its revolutionary design features that enhance efficiency and functionality. With its unique modular design, this gearbox allows for easy scalability and customization depending on specific industrial needs. According to a recent market report by ResearchAndMarkets, the global gear market is projected to reach $300 billion by 2025, emphasizing the increasing demand for adaptable solutions in various sectors, including automotive, construction, and aerospace. The Sewmkygearbox's ability to reduce energy consumption by up to 20% sets it apart, making it an attractive option for industries looking to lower operational costs while maintaining high performance.

Furthermore, the integration of smart technology within the Sewmkygearbox allows for real-time monitoring and predictive maintenance. An industry analysis from McKinsey & Company highlights that businesses implementing IoT-based solutions can experience a 20-30% reduction in maintenance costs. By adopting the Sewmkygearbox, companies not only benefit from advanced durability and lower weight but also gain insights into performance metrics, ultimately leading to improved decision-making and maximized uptime. These innovative design features position the Sewmkygearbox as a game-changer in the machinery landscape.

Understanding the Unique Mechanics Behind Sewmkygearbox

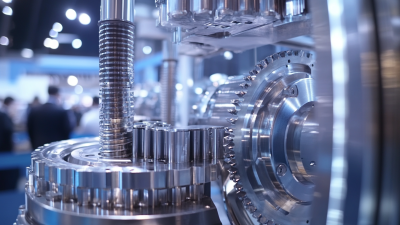

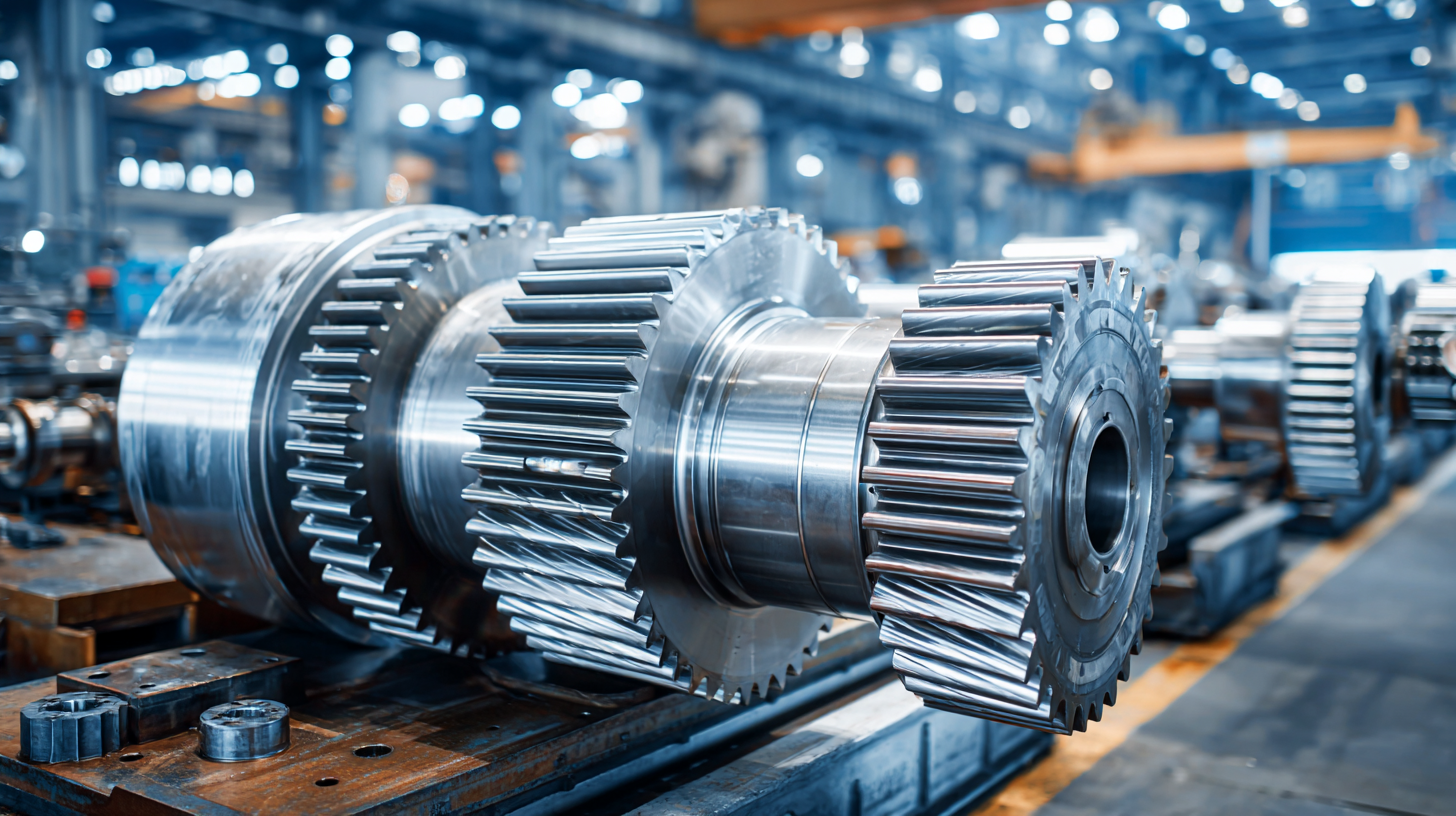

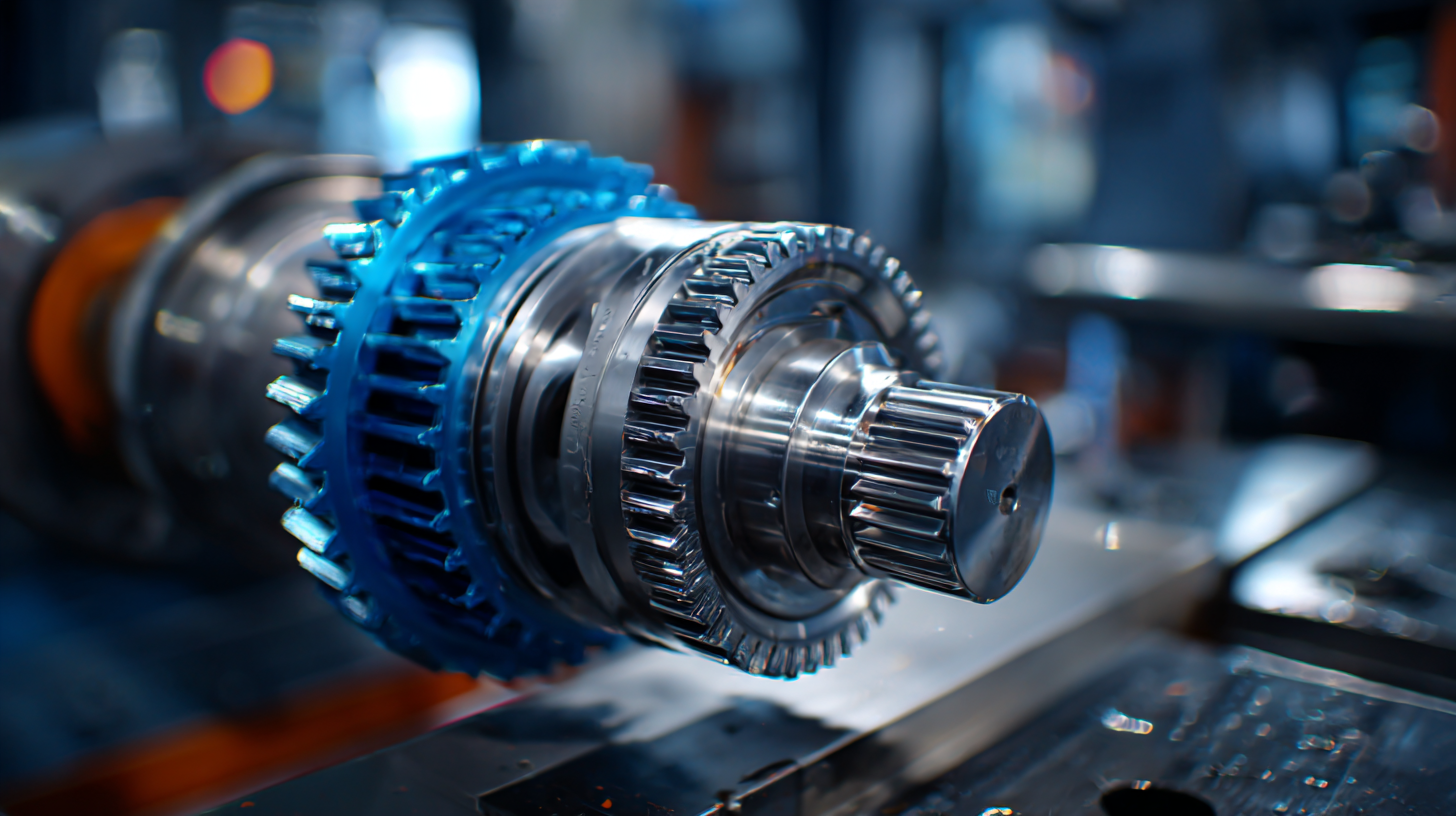

The Sewmkygearbox represents a leap in mechanical engineering, integrating advanced design principles to enhance operational efficiency in modern machinery. At its core, the unique mechanics of the Sewmkygearbox utilize a combination of planetary gear arrangements and high-precision components that allow for smooth power transmission. This design reduces friction and energy loss, thus improving overall energy efficiency during operation.

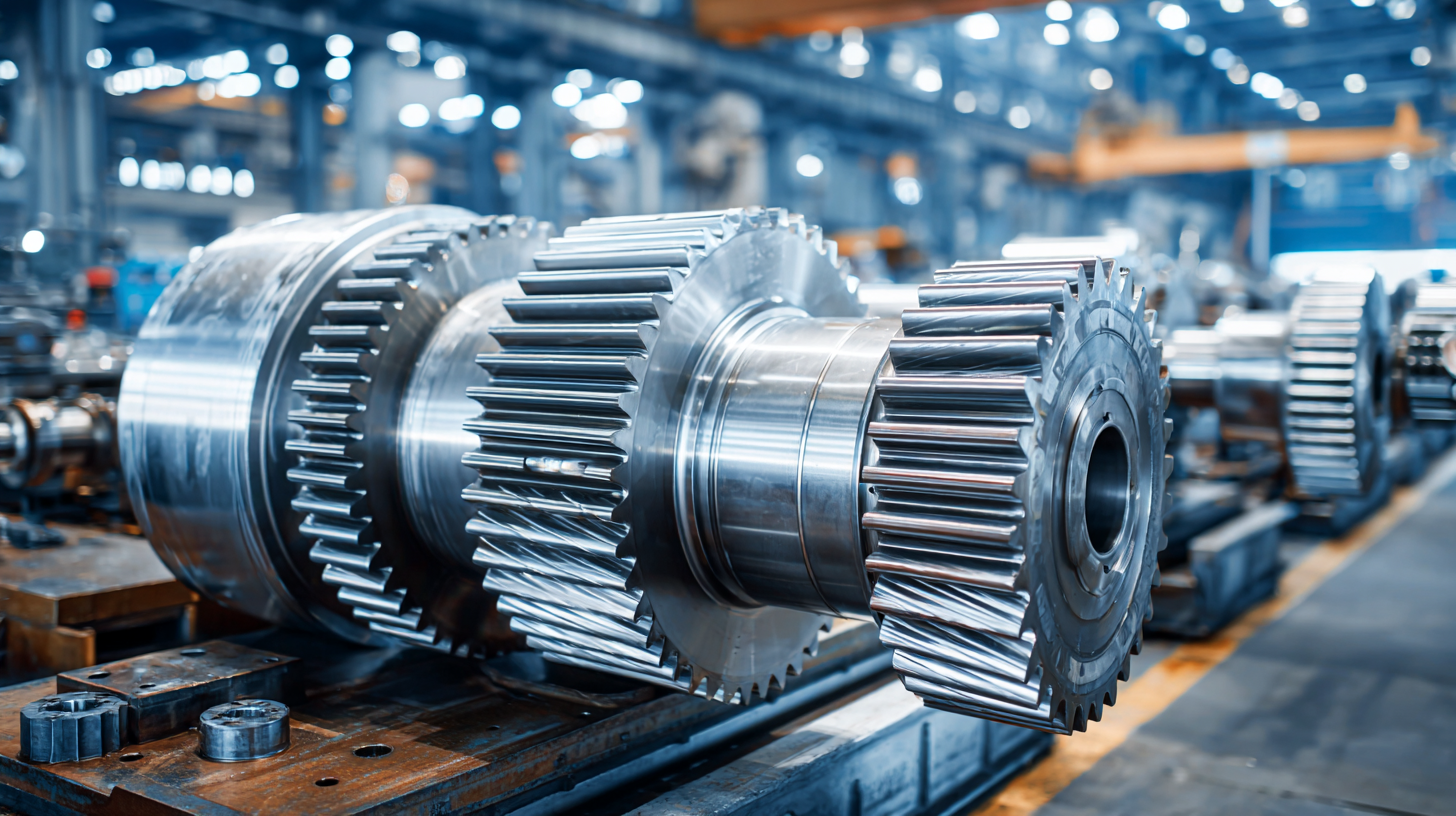

Additionally, the modular structure of the Sewmkygearbox offers significant flexibility in industrial applications. With interchangeable parts, it can be easily adapted to various machinery setups, making it an ideal choice for manufacturers looking to optimize their systems without the need for complete overhauls. This adaptability not only streamlines maintenance efforts but also prolongs the lifespan of the machinery, ultimately leading to reduced downtime and maintenance costs. Furthermore, the innovative use of lightweight materials in the construction of the Sewmkygearbox contributes to its superior performance, allowing for greater load capacities without a corresponding increase in weight.

Comparative Analysis: Sewmkygearbox vs. Traditional Gearboxes

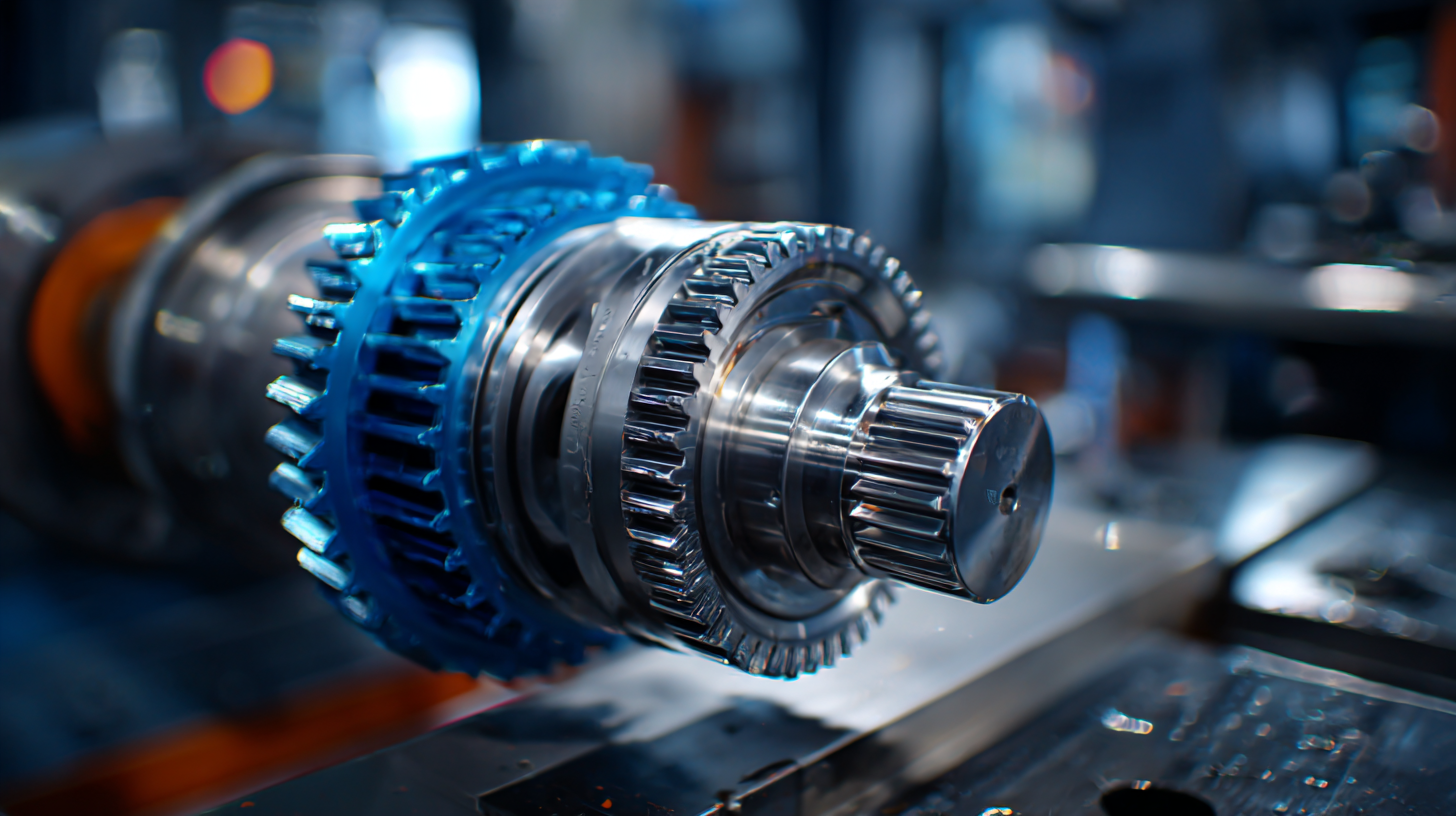

The introduction of Sewmkygearbox technology has been a game-changer in the field of modern machinery. When compared to traditional gearboxes, Sewmkygearbox demonstrates remarkable advantages in efficiency, weight reduction, and operational durability. For instance, the unique design of Sewmkygearbox allows for smoother transmission of power, which enhances overall machine performance. This is particularly beneficial for industries that require precision and reliability in their operations, such as automotive and aerospace engineering.

Tips for transitioning to Sewmkygearbox include conducting a thorough compatibility assessment with existing machinery. Understanding the specifications and performance requirements is crucial to ensure seamless integration. Additionally, consider starting with a pilot project to evaluate the benefits in real-world applications before full-scale implementation. This approach allows teams to gather data and make informed adjustments for optimal performance.

In contrast to traditional gearboxes, which often suffer from higher friction and wear, Sewmkygearbox employs advanced materials and engineering techniques that minimize these issues. As a result, users can expect lower maintenance costs and extended service life. The lower weight of Sewmkygearbox also contributes to overall energy savings, making it an attractive option for companies aiming to reduce their carbon footprint without sacrificing performance.

Real-World Applications of Sewmkygearbox in Various Industries

The Sewmkygearbox, renowned for its innovative design and high efficiency, is making a significant impact across various industries. In the manufacturing sector, for instance, its precision engineering allows for smoother operations in assembly lines, enhancing productivity while reducing energy consumption. This gearbox's unique features, such as adaptive torque control, enable machines to perform optimally under varying loads, leading to minimal downtime and maintenance costs.

The Sewmkygearbox, renowned for its innovative design and high efficiency, is making a significant impact across various industries. In the manufacturing sector, for instance, its precision engineering allows for smoother operations in assembly lines, enhancing productivity while reducing energy consumption. This gearbox's unique features, such as adaptive torque control, enable machines to perform optimally under varying loads, leading to minimal downtime and maintenance costs.

In the renewable energy sector, Sewmkygearbox is revolutionizing wind turbine technologies. Its lightweight construction and robust performance ensure that wind turbines operate efficiently even in low-wind conditions. This efficiency not only maximizes energy output but also contributes to lowering operational costs. Furthermore, in the automotive industry, the integration of Sewmkygearbox in electric vehicles facilitates improved energy transfer and propulsion systems, making them more sustainable and efficient. These real-world applications highlight the versatility and transformative potential of Sewmkygearbox in modern machinery, driving innovation across diverse fields.

Future Trends: The Evolution of Gearbox Technology with Sewmkygearbox

The evolution of gearbox technology has been significantly influenced by innovative designs such as Sewmkygearbox, which promise to reshape the machinery landscape. As industries increasingly demand more efficient and reliable solutions, advancements in gearbox technology are becoming essential. Sewmkygearbox stands out with its unique integration of materials and design principles that enhance performance while reducing operational costs. The focus on energy efficiency and increased durability positions this innovative gearbox as a crucial player in the market.

Looking ahead, the gearbox sector is poised for substantial growth, driven by the integration of smart technologies and automation in industrial machinery. Research indicates a booming industrial gearbox market by 2031, fueled by the need for adaptable and technologically advanced components. As manufacturers adapt to evolving demands, Sewmkygearbox is likely to play a pivotal role in this transformation, offering solutions that not only meet current standards but also anticipate future challenges in various applications. The continuous evolution of gearbox technology will shape the future, ensuring that machinery operates at optimal efficiency and reliability.

Exploring the Innovative Benefits of Sewmkygearbox in Modern Machinery

| Feature |

Description |

Potential Benefits |

Future Trends |

| Modular Design |

Interchangeable components for easy upgrades and maintenance. |

Reduced downtime and maintenance costs. |

Increased adoption of modular systems in complex machinery. |

| Smart Sensors |

Integration of IoT sensors for performance monitoring. |

Real-time data analysis for predictive maintenance. |

Rise of Industry 4.0 with connected machinery. |

| Lightweight Materials |

Use of advanced composites and alloys in construction. |

Improved energy efficiency and performance. |

Trend toward lightweight machinery in various industries. |

| Energy Recovery |

Systems to reclaim energy during operation. |

Lower energy costs and improved sustainability. |

Increasing focus on sustainable manufacturing practices. |

| Enhanced Durability |

Use of improved coatings and treatments. |

Longer lifespan and reduced failure rates. |

Continued advancements in material science. |

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor As businesses strive to optimize performance and cut operational costs, understanding how to integrate and leverage the Sewmkygearbox in modern machinery becomes crucial. This article delves into the myriad benefits offered by the Sewmkygearbox and provides practical insights into its application in today's competitive landscape.

As businesses strive to optimize performance and cut operational costs, understanding how to integrate and leverage the Sewmkygearbox in modern machinery becomes crucial. This article delves into the myriad benefits offered by the Sewmkygearbox and provides practical insights into its application in today's competitive landscape.

The Sewmkygearbox, renowned for its innovative design and high efficiency, is making a significant impact across various industries. In the manufacturing sector, for instance, its precision engineering allows for

The Sewmkygearbox, renowned for its innovative design and high efficiency, is making a significant impact across various industries. In the manufacturing sector, for instance, its precision engineering allows for