5 Expert Tips to Maximize the Efficiency of Your Planetary Gearbox

In the realm of mechanical engineering, the planetary gearbox stands out as a vital component that enhances the efficiency and performance of various machinery. As industries continue to seek innovative solutions for power transmission, understanding the types and functionalities of planetary gearboxes becomes crucial. This blog delves into five expert tips aimed at maximizing the efficiency of your planetary gearbox, ensuring optimal output and longevity. Whether you are involved in design, maintenance, or operation, grasping these insights will empower you to harness the full potential of your planetary gearbox, streamline your operations, and ultimately, improve your productivity.

Join us as we explore essential strategies and considerations that can help you get the most out of this remarkable engineering marvel.

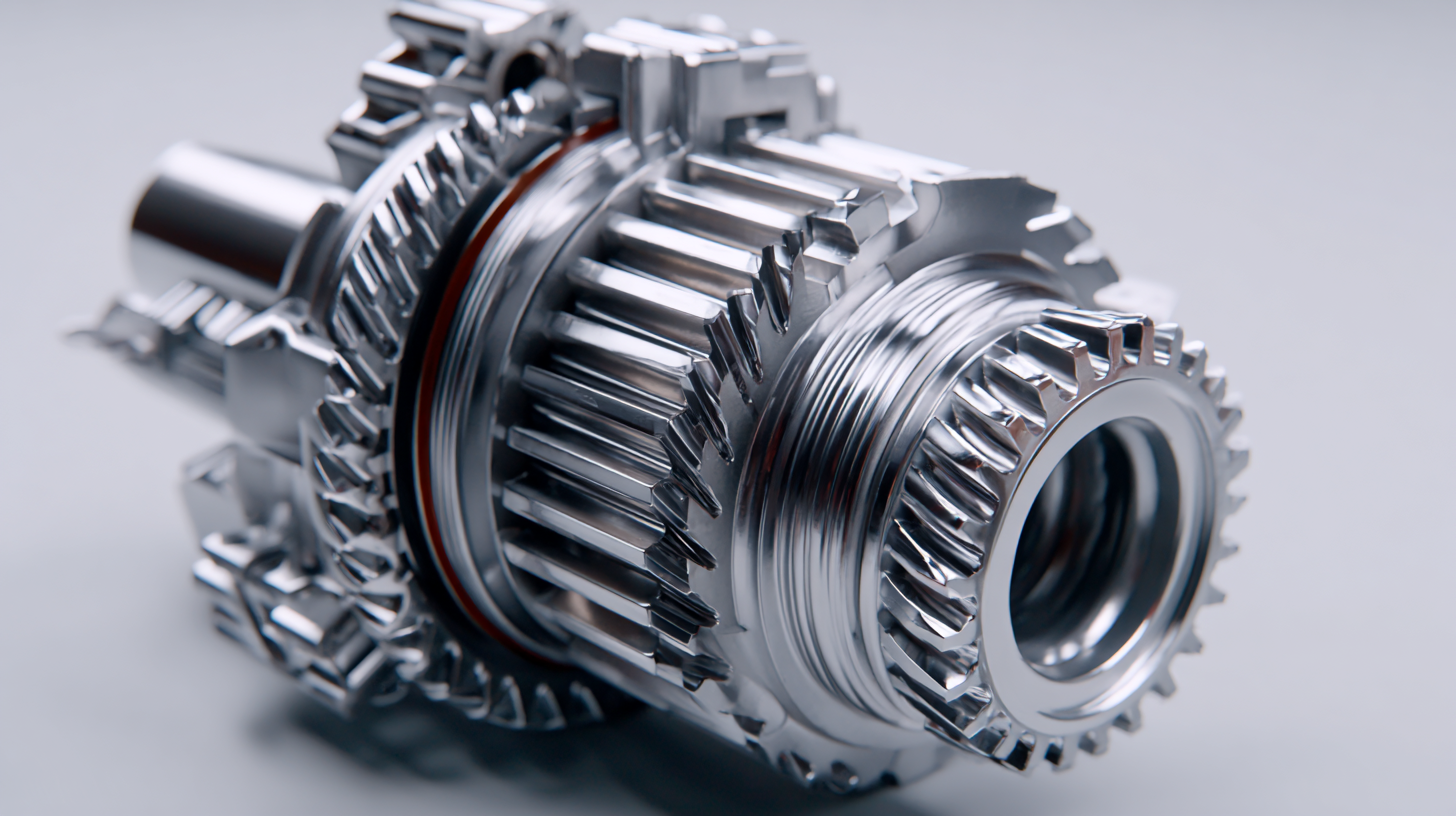

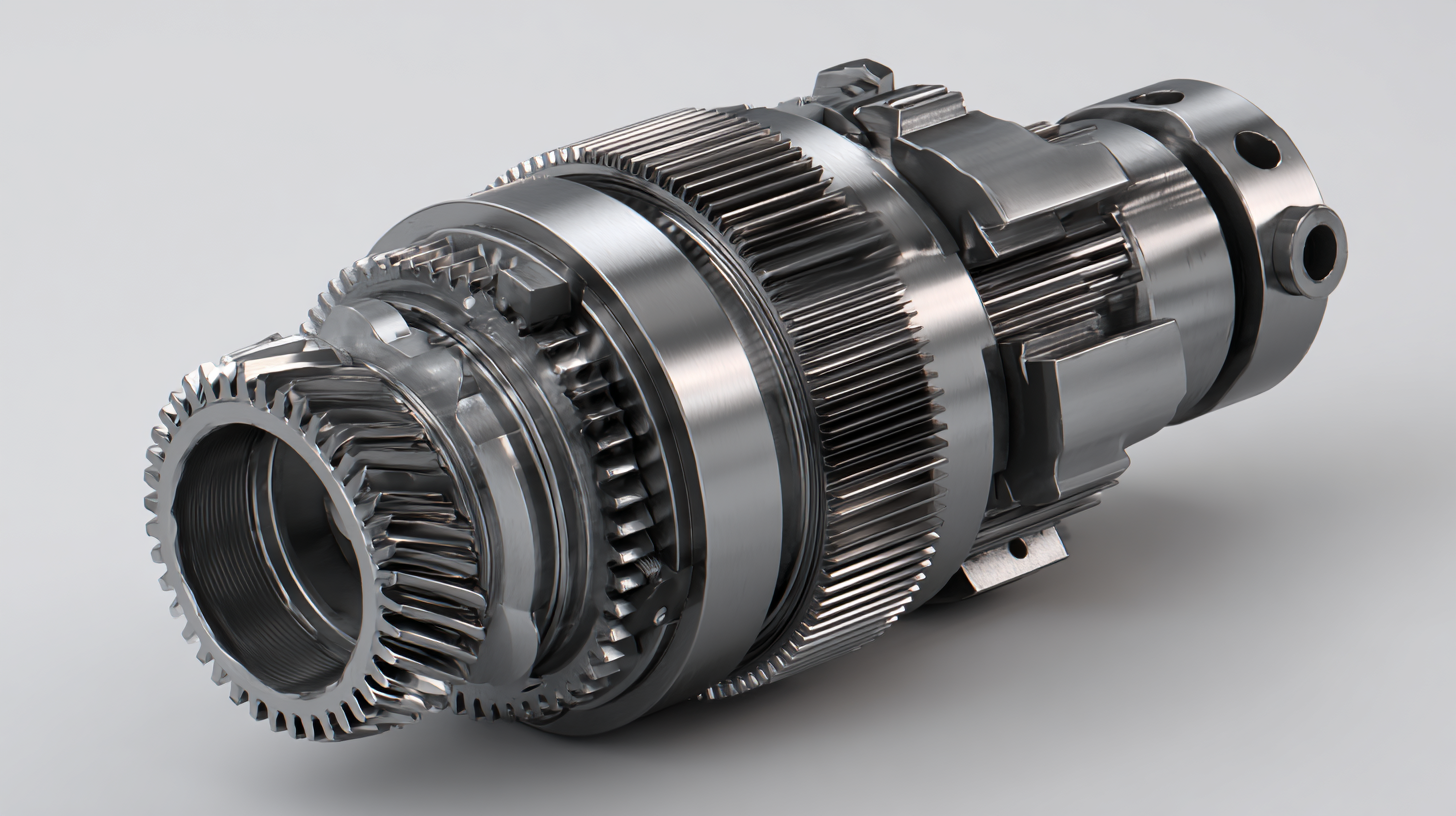

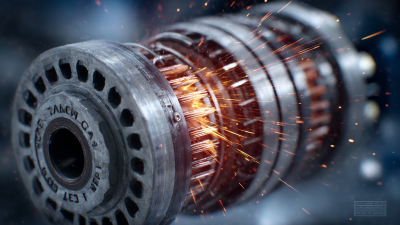

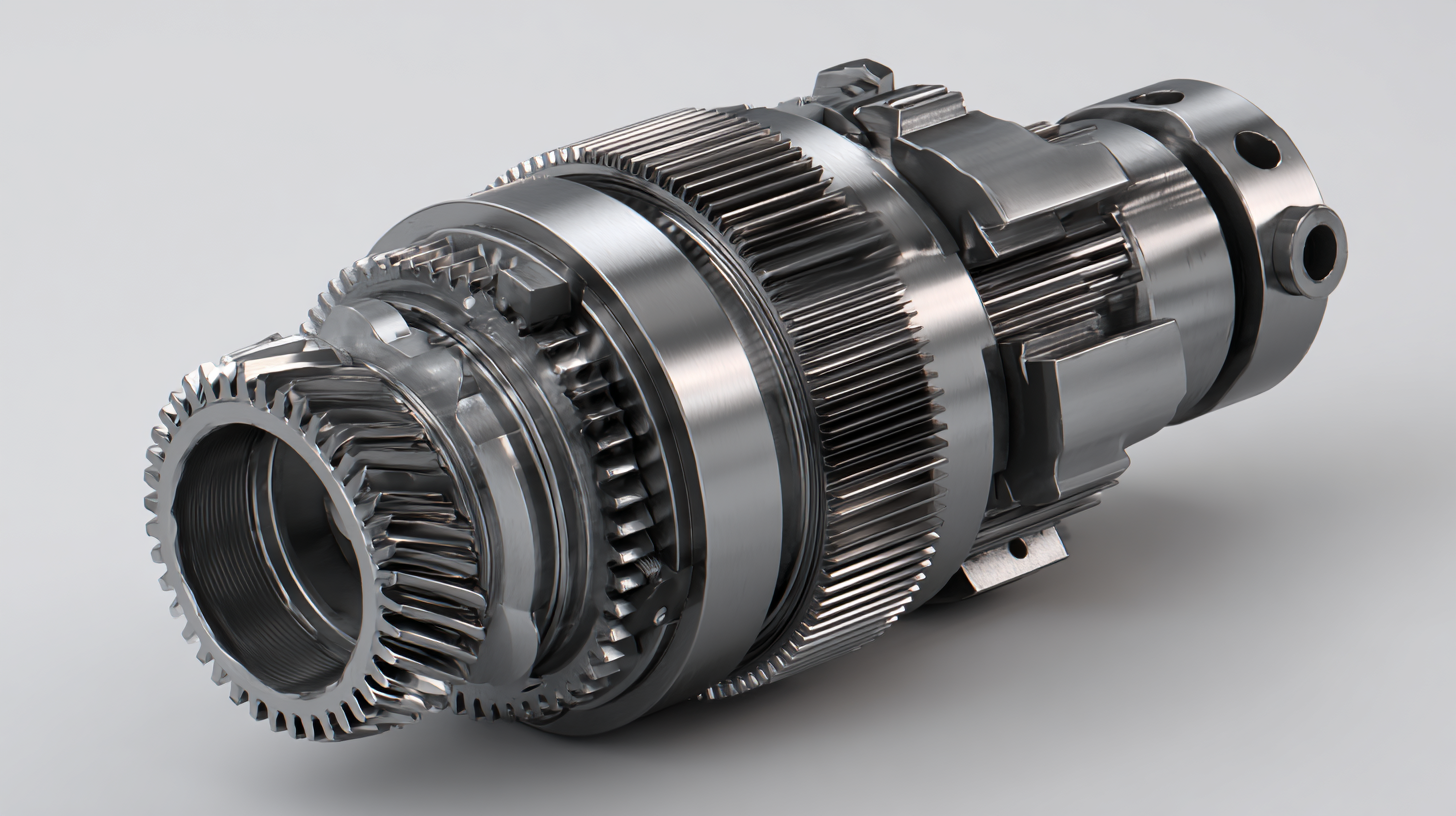

Understanding the Essential Components of a Planetary Gearbox

A planetary gearbox is an intricate system composed of several essential components that work harmoniously to achieve high efficiency and torque multiplication. At the core of this gearbox are planet gears, which orbit around a central sun gear. This arrangement allows for a compact design while distributing load evenly, enhancing the system's longevity and performance. The ring gear encases the planet gears, providing a contact surface that complements their rotation. Understanding this gear configuration is crucial for optimizing its application in various mechanical systems.

Another critical component is the carrier that holds the planet gears in place, allowing for smooth movement and efficient power transmission. The precise alignment of these parts ensures that the gearbox operates without excessive wear or heat generation, both of which can diminish efficiency over time. Additionally, lubrication is vital for minimizing friction between the moving parts, which further enhances the overall performance of the planetary gearbox. By recognizing these essential components and their roles, operators can make informed decisions in maintenance and operation, ultimately maximizing efficiency and extending the lifespan of their systems.

5 Expert Tips to Maximize the Efficiency of Your Planetary Gearbox

| Tip |

Description |

Key Component |

Efficiency Gain (%) |

| 1. Proper Lubrication |

Ensure adequate lubrication for smooth operation and reduced friction. |

Lubricants |

15% |

| 2. Regular Maintenance |

Schedule regular inspections to identify and resolve issues early. |

Bearings |

20% |

| 3. Optimize Gear Ratio |

Choose the right gear ratio to match application requirements for improved torque and speed. |

Gear Set |

25% |

| 4. Load Monitoring |

Implement load sensing to prevent overload conditions. |

Sensors |

30% |

| 5. Vibration Analysis |

Conduct vibration analysis to detect imbalances and misalignments. |

Balancing Components |

18% |

Identifying Common Efficiency Issues in Planetary Gearbox Systems

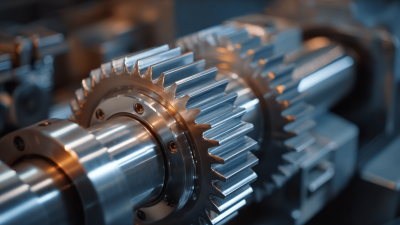

Planetary gearboxes are renowned for their compact design and high torque density; however, their efficiency can be significantly affected by several common issues. Research from the American Gear Manufacturers Association indicates that misalignment is a primary culprit, leading to energy losses that can reach up to 20%. Proper alignment reduces unnecessary wear and heat generation, thereby enhancing overall system efficiency. Investigating wear and tear on the gears can also reveal insights into efficiency problems; excessive friction caused by lubrication issues can contribute to energy losses and increase operational costs.

Planetary gearboxes are renowned for their compact design and high torque density; however, their efficiency can be significantly affected by several common issues. Research from the American Gear Manufacturers Association indicates that misalignment is a primary culprit, leading to energy losses that can reach up to 20%. Proper alignment reduces unnecessary wear and heat generation, thereby enhancing overall system efficiency. Investigating wear and tear on the gears can also reveal insights into efficiency problems; excessive friction caused by lubrication issues can contribute to energy losses and increase operational costs.

Another critical factor impacting the efficiency of planetary gearbox systems is the quality of materials used in their construction. Study findings by the International Gear Conference suggest that using high-quality, low-friction materials can improve efficiency by as much as 15%-30%. Implementing improved manufacturing processes, such as precision machining, further minimizes tolerances that could lead to energy loss. Additionally, regular inspection and maintenance schedules can help identify these common efficiency issues early, preventing costly downtime and improving the lifespan of the gearbox systems.

Implementing Effective Lubrication Strategies for Optimized Performance

Effective lubrication is critical for maximizing the performance of planetary gearboxes. A well-lubricated system reduces friction and wear, ensuring smooth operation and extending the lifespan of your equipment. One of the most important tips is to choose the right lubricant for your specific application. Different gearboxes may require different types of oils or greases, so always consult the manufacturer's recommendations and select a lubricant that can withstand the operating conditions, including temperature and load.

Additionally, proper lubrication intervals are essential to maintain optimal performance. Regularly scheduled maintenance should include checks on the lubrication levels and replenishment as needed. Creating a lubrication schedule based on the operating environment and gearbox usage can help prevent degradation of lubricant properties over time. In some cases, implementing diagnostic tools to monitor lubricant condition can provide further insights into when to perform maintenance.

Lastly, consider the lubrication method. Whether opting for manual lubrication, oil mist systems, or centralized lubrication, selecting the right method for your operation can enhance efficiency. Automated systems can ensure a consistent supply of lubricant, reducing the likelihood of human error and ensuring that all components receive the appropriate amount of lubrication. Prioritizing these lubrication strategies will lead to a more efficient and reliable planetary gearbox operation.

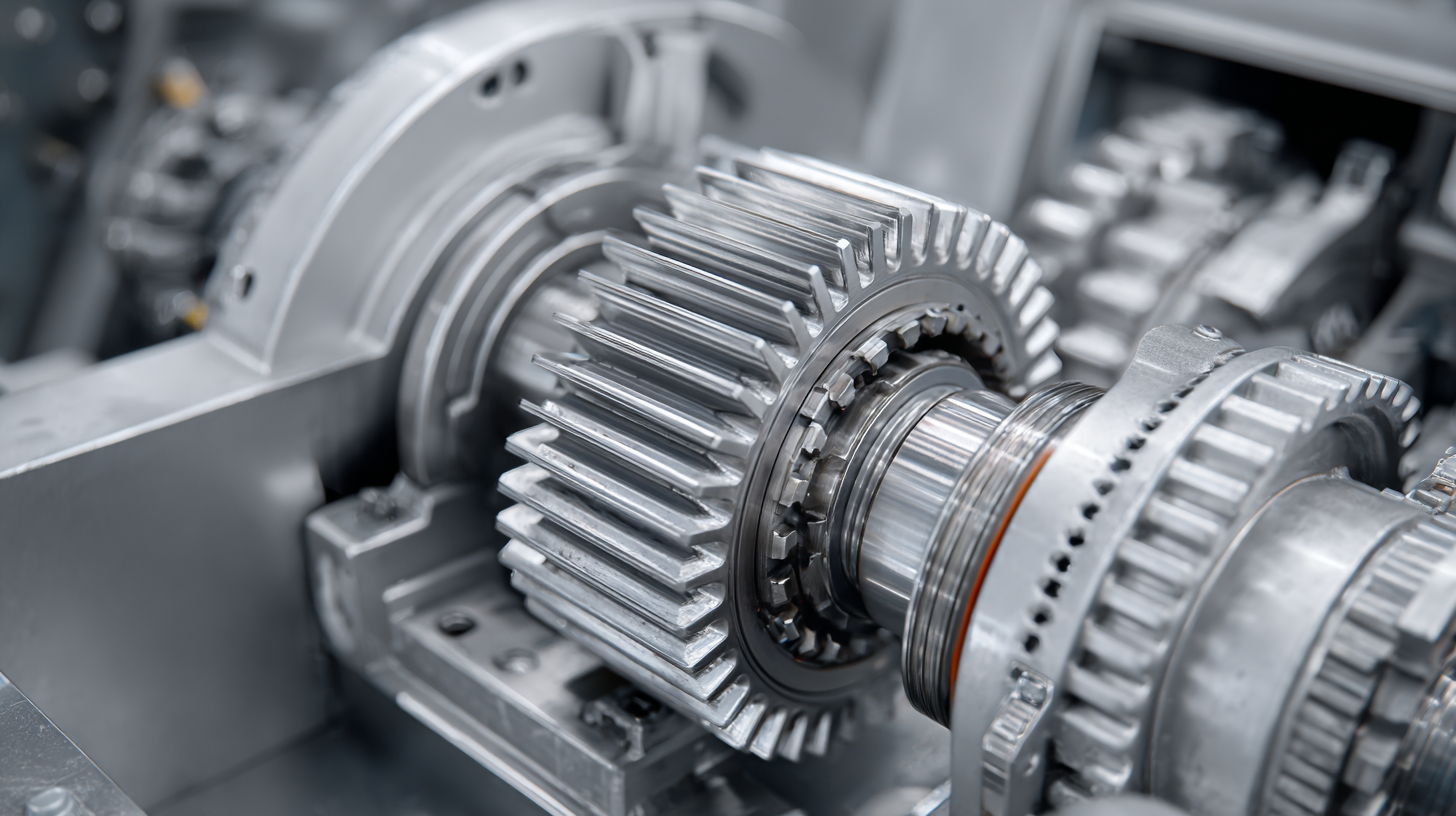

Regular Maintenance Practices to Enhance Gearbox Lifespan and Efficiency

Regular maintenance practices are essential for enhancing both the lifespan and efficiency of planetary gearboxes. According to a report by the Gear Planetary Association, a well-maintained gearbox can achieve an efficiency increase of up to 15%, thereby significantly reducing operational costs. Regular inspections and lubrication not only prevent wear and tear but also minimize energy losses caused by friction. Gearbox components should be checked for signs of overheating or abnormal noise, which can indicate underlying issues that need immediate attention.

Moreover, implementing a proactive maintenance schedule can extend the operational life of a planetary gearbox. Research indicates that two-thirds of gearbox failures stem from inadequate maintenance practices, which often lead to costly downtimes. By adhering to a routine that includes checking oil levels, replacing filters, and monitoring operating temperatures, businesses can effectively reduce the probability of unexpected failures. This approach not only aids in preserving the gearbox’s efficiency but also contributes to a more sustainable operation, as longer-lasting equipment means fewer resources consumed over time.

Gearbox Maintenance Efficiency Over Time

This bar chart illustrates the efficiency of a planetary gearbox as it undergoes regular maintenance practices over time. Initially, efficiency increases significantly due to proper lubrication and alignment. However, after two years, efficiency may decline if maintenance practices are not consistently followed.

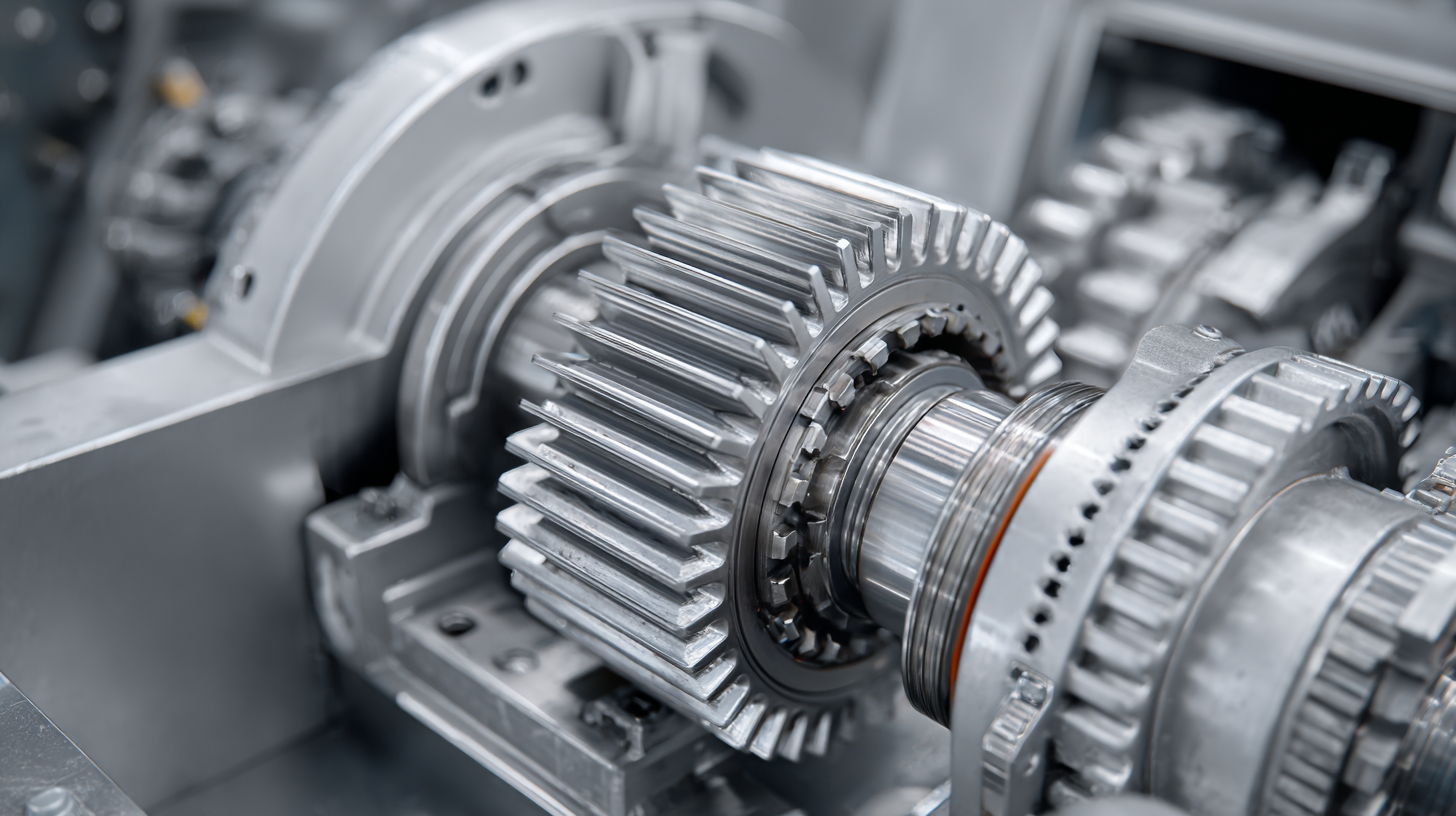

Best Practices for Proper Load Management in Gearbox Operations

In the world of planetary gearboxes, effective load management is crucial to optimize performance and longevity. According to a report from Gear Technology, improper load distribution can lead to a significant reduction in gearbox efficiency, with up to 30% higher wear rates in gears subjected to uneven loads. To combat this, implementing proper load management strategies is essential.

One best practice is to ensure that the load applied to the gearbox is within the manufacturer's specified limits. This not only helps in maintaining efficiency but also extends the operational life of the gearbox. A study by the American Gear Manufacturers Association highlights that adhering to load limits can reduce the incidence of premature failures by nearly 40%. Additionally, regular monitoring and adjustments based on operational data can help identify potential issues before they escalate, allowing for corrective measures to be implemented promptly.

Another important aspect is the alignment of the gearbox with the connected components. Misalignment can create unnecessary stress on the gearbox, ultimately leading to failure. Research indicates that even a slight misalignment, as little as 0.5 degrees, can increase load on the bearings and cause a decrease in efficiency of up to 20%. Therefore, maintaining precise alignment is critical for optimal gearbox performance and reliable operation.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor