How to Optimize Efficiency with Siemensmkygearbox in Industrial Applications

In today's competitive industrial landscape, optimizing efficiency has become paramount for organizations aiming to enhance productivity and reduce operational costs. According to a report by the International Energy Agency, industrial energy consumption accounts for approximately 54% of global energy demand, highlighting the critical need for technologies that improve energy efficiency. One such solution is the Siemensmkygearbox, renowned for its superior performance and reliability. This advanced gearbox not only minimizes energy losses but also enables seamless integration into various industrial applications, ranging from manufacturing to renewable energy. By leveraging the capabilities of the Siemensmkygearbox, companies can achieve significant reductions in downtime and maintenance costs while maximizing throughput, ultimately positioning themselves for sustainable growth in an ever-evolving market.

Understanding the Siemensmkygearbox: Key Features and Advantages

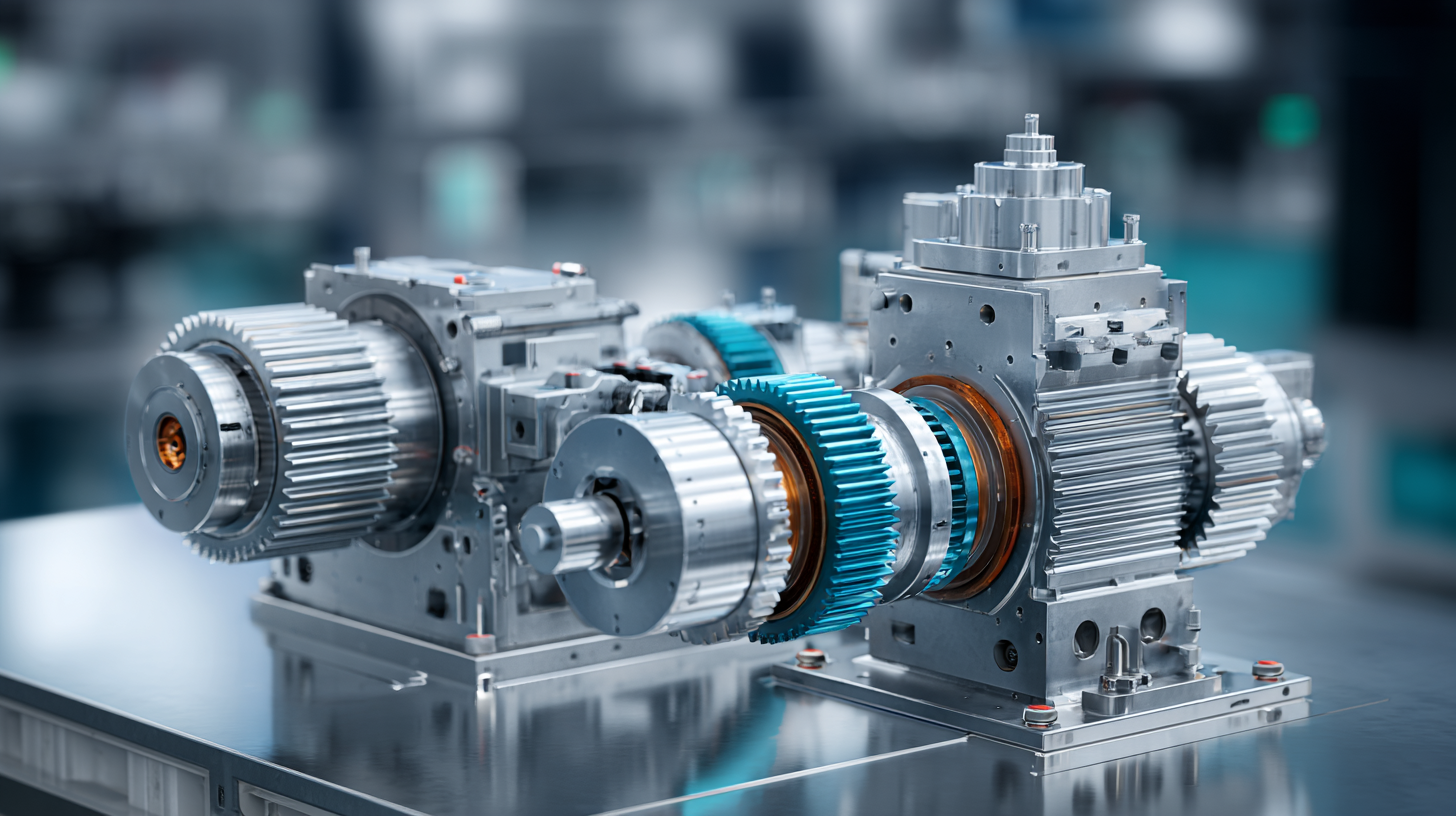

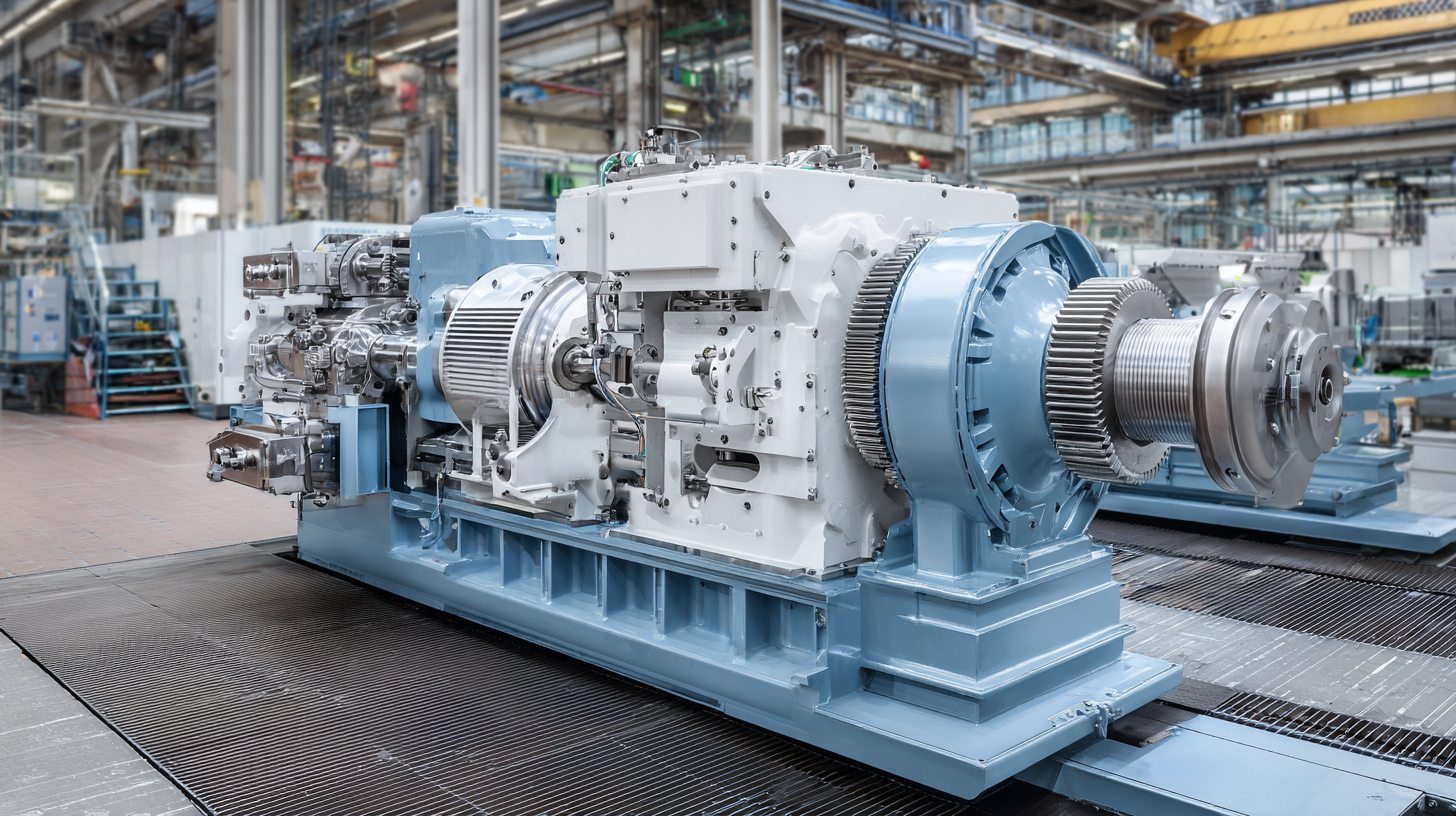

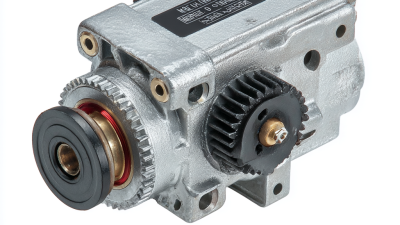

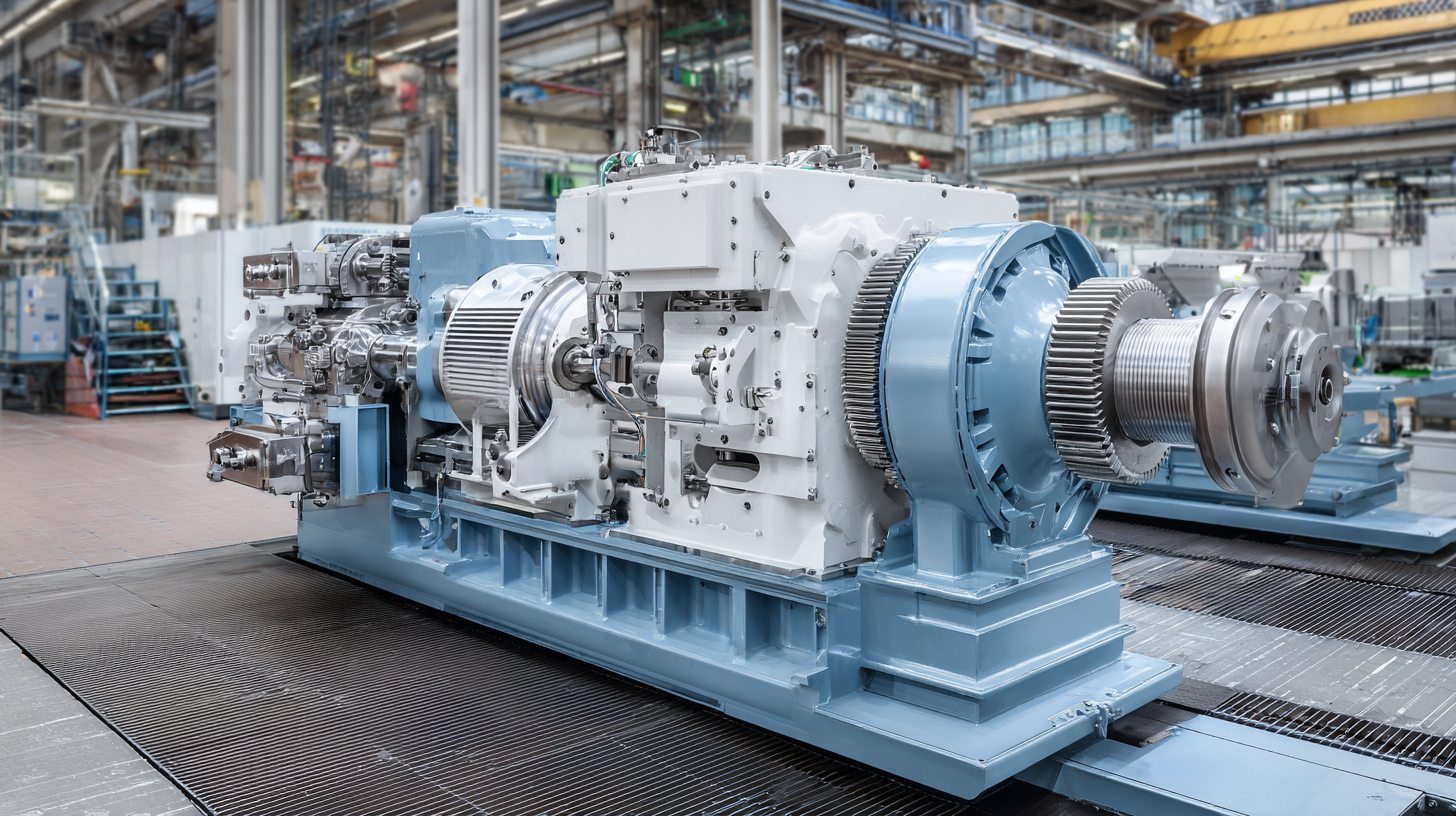

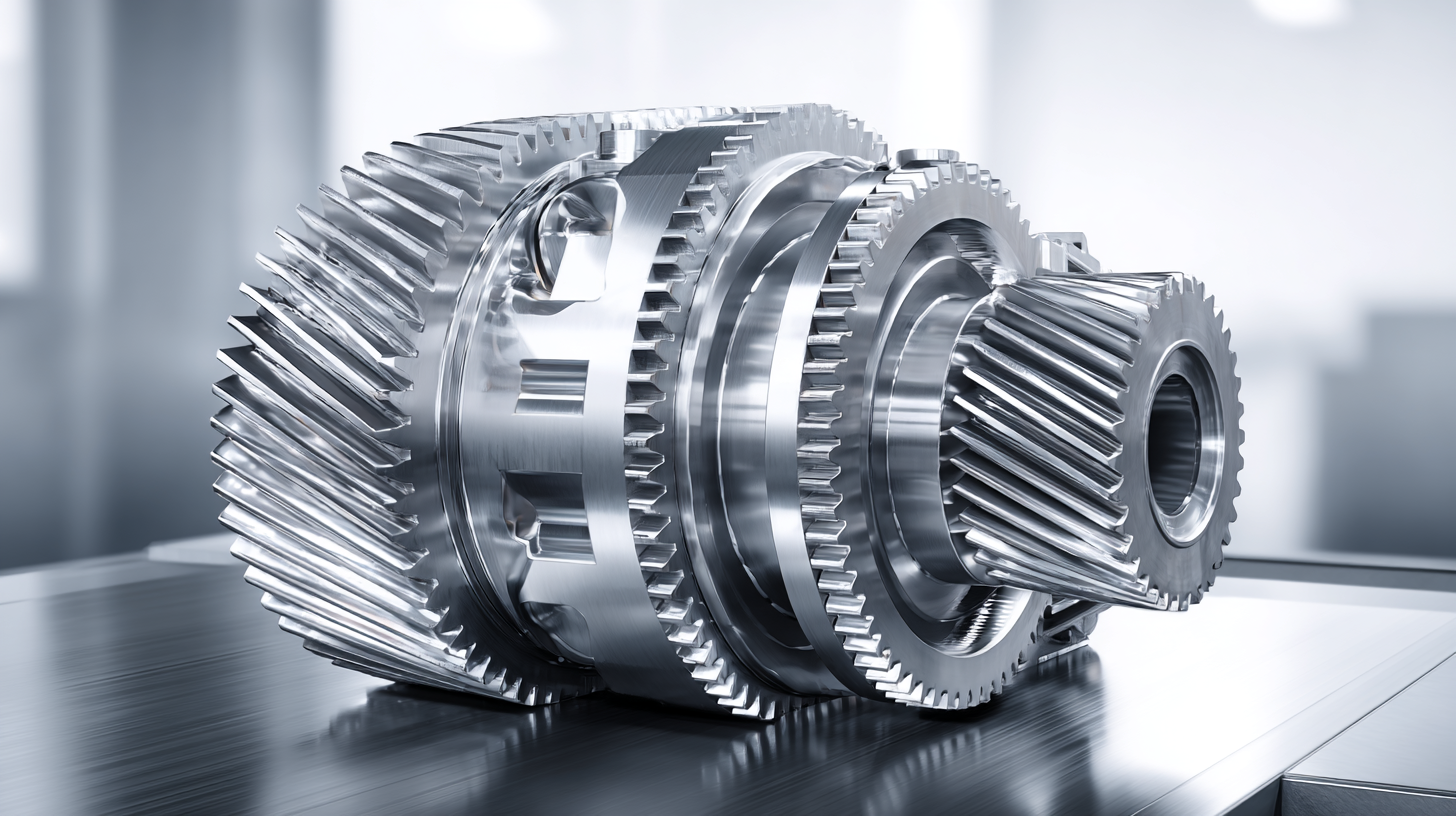

The Siemensmkygearbox is engineered to enhance operational efficiency in various industrial applications. Its key features include high durability, versatile torque outputs, and integration with advanced drive technology, enabling seamless compatibility with different motor systems. By harnessing perfectly coordinated drive components from a single source, the Siemensmkygearbox supports automated processes and optimizes performance across a range of settings.

One of the notable advantages of the Siemensmkygearbox is its adaptability to demanding environments, making it suitable for industries such as manufacturing and energy production. With ongoing innovations and expansions in production capacity, particularly in emerging markets, these gearboxes are designed to deliver reliable performance while mitigating the operational costs associated with maintenance and downtime. This positions the Siemensmkygearbox as a pivotal solution for businesses looking to elevate their efficiency and sustain competitive advantages in an evolving industrial landscape.

Selecting the Right Siemensmkygearbox for Your Industrial Needs

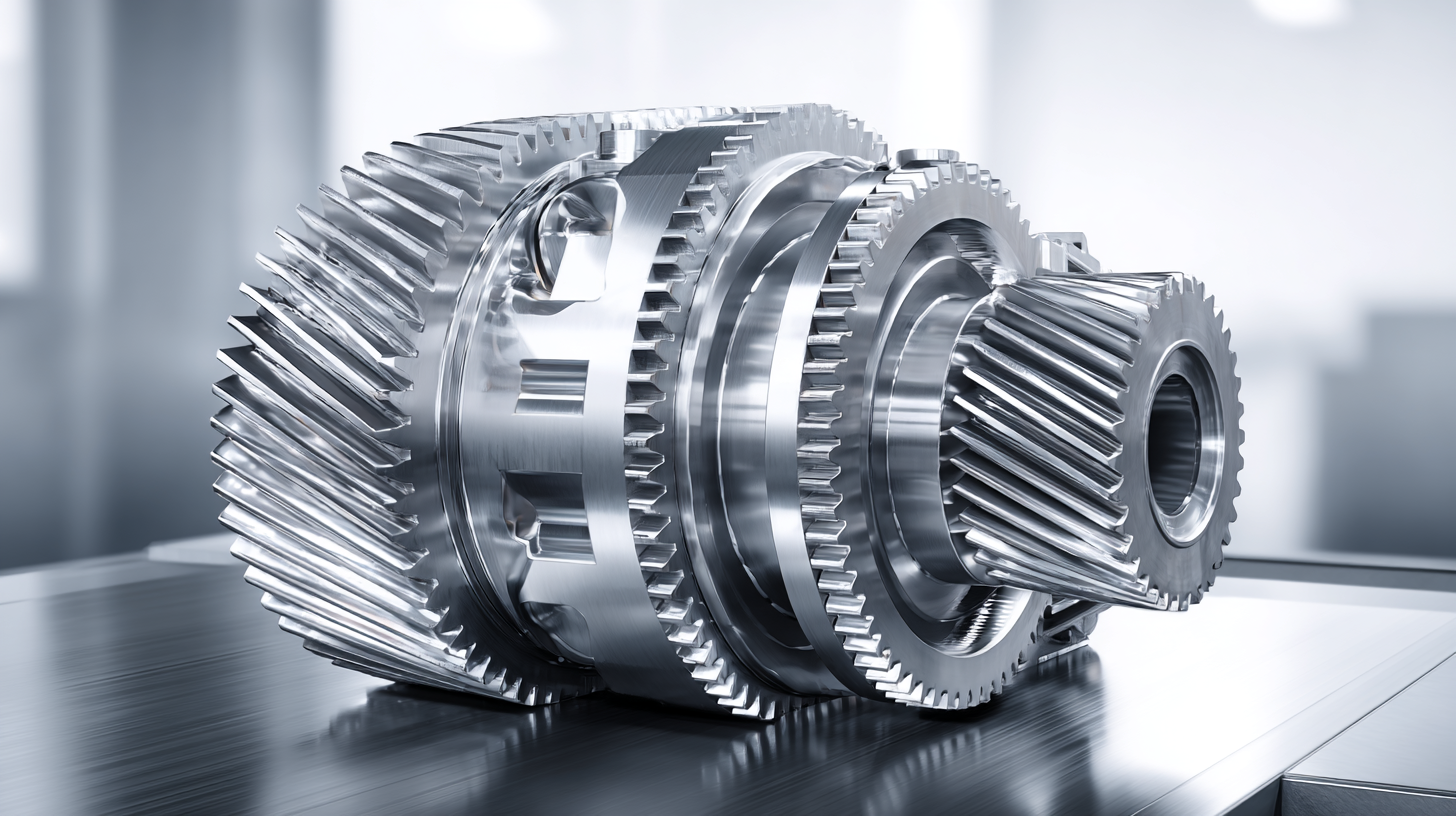

When selecting the right Siemensmkygearbox for your industrial applications, it's crucial to consider the specific requirements of your operations. Different industries may demand various features, such as load capacity, speed, and environmental resistance. For example, heavy-duty applications may require gearboxes designed to handle higher torque loads, while processes involving continuous operation may benefit from gearboxes engineered for longevity and low maintenance. Understanding these needs will guide you in choosing the optimal model that not only meets operational demands but also enhances overall efficiency.

Another important factor to consider is the compatibility of the Siemensmkygearbox with existing machinery. Ensure that the gearbox fits seamlessly into your current system's design and operational parameters to avoid potential integration issues. Additionally, consulting with Siemens representatives or utilizing their detailed product specifications can aid in making informed decisions. By focusing on both performance capabilities and compatibility, you can optimize efficiency and reliability in your industrial processes.

Best Practices for Installation and Maintenance of Siemensmkygearbox

When it comes to optimizing the efficiency of Siemensmkygearbox in industrial applications, proper installation and maintenance are key components. According to a report by MarketsandMarkets, effective maintenance of mechanical systems can improve operational efficiency by up to 25%. To ensure that your Siemensmkygearbox operates at peak performance, it’s essential to adhere to best practices in its installation. This includes ensuring accurate alignment with driven machinery to minimize wear and energy loss, as misalignment can lead to up to 50% increases in failure rates over time.

Additionally, regular maintenance schedules should not be overlooked. The American National Standards Institute (ANSI) recommends routine inspections every three to six months, which can significantly extend the gearbox's lifecycle. Key maintenance tasks include checking oil levels and quality, inspecting seals and gaskets for leaks, and monitoring operating temperatures. By utilizing predictive maintenance strategies, such as vibration analysis, companies can detect inefficiencies early, reducing downtime and potentially saving up to 20% in repair costs. Implementing these practices will help industries maximize the longevity and performance of their Siemensmkygearbox systems.

Performance Monitoring: Enhancing Efficiency with Data Analytics

In the realm of industrial applications, the integration of data analytics into performance monitoring plays a pivotal role in enhancing efficiency when utilizing Siemensmkygearboxes. By leveraging real-time data, companies can gain valuable insights into operational performance, identifying patterns and anomalies that may indicate inefficiencies. This approach allows for timely interventions and preventative maintenance, ensuring that the machinery operates at peak performance while minimizing downtime.

Moreover, the utilization of advanced data analytics tools enables organizations to forecast potential issues before they escalate, facilitating a proactive maintenance strategy. By analyzing historical performance data, companies can optimize gearbox settings and configurations tailored to specific operational demands. The result is not only improved efficiency but also a reduction in operational costs, as resources can be allocated more effectively based on predictive insights. With Siemensmkygearboxes, companies can harness the power of data analytics to refine their processes and achieve a sustainable competitive advantage in the marketplace.

How to Optimize Efficiency with Siemensmkygearbox in Industrial Applications - Performance Monitoring: Enhancing Efficiency with Data Analytics

| Parameter |

Value |

Unit |

Notes |

| Operational Efficiency |

87 |

% |

Measured during peak operation |

| Energy Consumption |

3500 |

kWh/week |

Estimate for typical load |

| Average Downtime |

4 |

hours/week |

Includes maintenance and repairs |

| Output Quality Rating |

9.5 |

/10 |

Based on recent quality assessments |

| Maintenance Frequency |

Once every |

3 months |

Routine checks and updates |

Troubleshooting Common Issues with Siemensmkygearbox in Operations

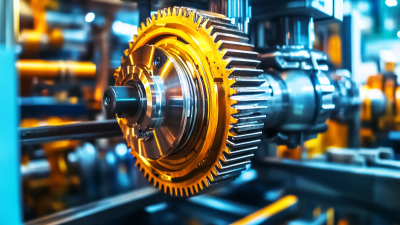

When utilizing Siemensmkygearbox in industrial applications, troubleshooting common issues is essential for maintaining operational efficiency. One prevalent problem users encounter is gear slippage, which can occur due to improper installation or wear over time. It's crucial to regularly inspect the gearbox for signs of misalignment, as even slight deviations can lead to significant performance issues. Ensuring that the gearbox is correctly aligned and secured can help mitigate these risks and enhance overall functionality.

Another common issue involves overheating, which can be attributed to inadequate lubrication or excessive load. Regular maintenance that includes checking lubrication levels and replacing worn components can prevent these situations. Additionally, monitoring load conditions and ensuring that the gearbox is not overburdened can significantly extend its lifespan and improve operational effectiveness. By being proactive in identifying and addressing these issues, operators can maximize the performance and reliability of the Siemensmkygearbox in their industrial processes.

Optimization of Siemens MKY Gearbox Efficiency in Industrial Applications

This chart illustrates the distribution of efficiency levels observed in Siemens MKY gearboxes used in industrial applications. The majority of cases fall under 'High Efficiency', indicating effective operations, while a smaller segment experiences 'Low Efficiency' which may require troubleshooting.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor