Unlocking Efficiency: How Bonfiglioli Planetary Gearboxes are Revolutionizing Industrial Operations Worldwide

In today's fast-paced industrial landscape, efficiency is paramount for businesses striving to maintain competitiveness. According to a recent report by MarketsandMarkets, the global gearbox market is projected to reach $34.4 billion by 2026, reflecting an increasing demand for innovative gear systems that enhance operational capabilities. Among the leading technologies shaping this evolution, Gearboxbonfiglioliplanetarygear stands out for its ability to deliver superior performance and reliability. Bonfiglioli's planetary gearboxes are designed to optimize power transmission and reduce energy consumption, addressing the ongoing need for sustainable industrial solutions. With advancements in engineering and a focus on customization, these gearboxes are not only enhancing productivity but also revolutionizing operational standards across various sectors worldwide, from manufacturing to renewable energy.

The Rise of Bonfiglioli Planetary Gearboxes in Industrial Applications

The industrial gearbox market is experiencing significant growth, driven by the rising demand for automation across various sectors. In 2023, the market size surpassed $29.5 billion, highlighting the increasing importance of reliable and efficient gear systems in facilitating smooth operations. From manufacturing to logistics, industries are seeking solutions that enhance productivity and operational efficiency, thus creating an ideal environment for advanced technologies to thrive.

Among these advancements, planetary gearboxes have emerged as a key player in industrial applications. With their unique design and superior torque capabilities, they enable machinery to operate more efficiently, reducing energy consumption and minimizing downtime. The expected compound annual growth rate of 4.5% from 2024 to 2032 signifies that manufacturers are increasingly investing in gearbox technologies that not only improve performance but also meet the growing demands for automation and precision in industrial processes.

As companies continue to embrace digital transformation, the rise of innovative gearbox solutions is revolutionizing operational frameworks worldwide. Efficient and reliable gearbox technology is no longer just a luxury; it is an essential component for modern industrial operations aiming to stay competitive in an ever-evolving market landscape.

Key Features of Bonfiglioli Gearboxes that Enhance Operational Efficiency

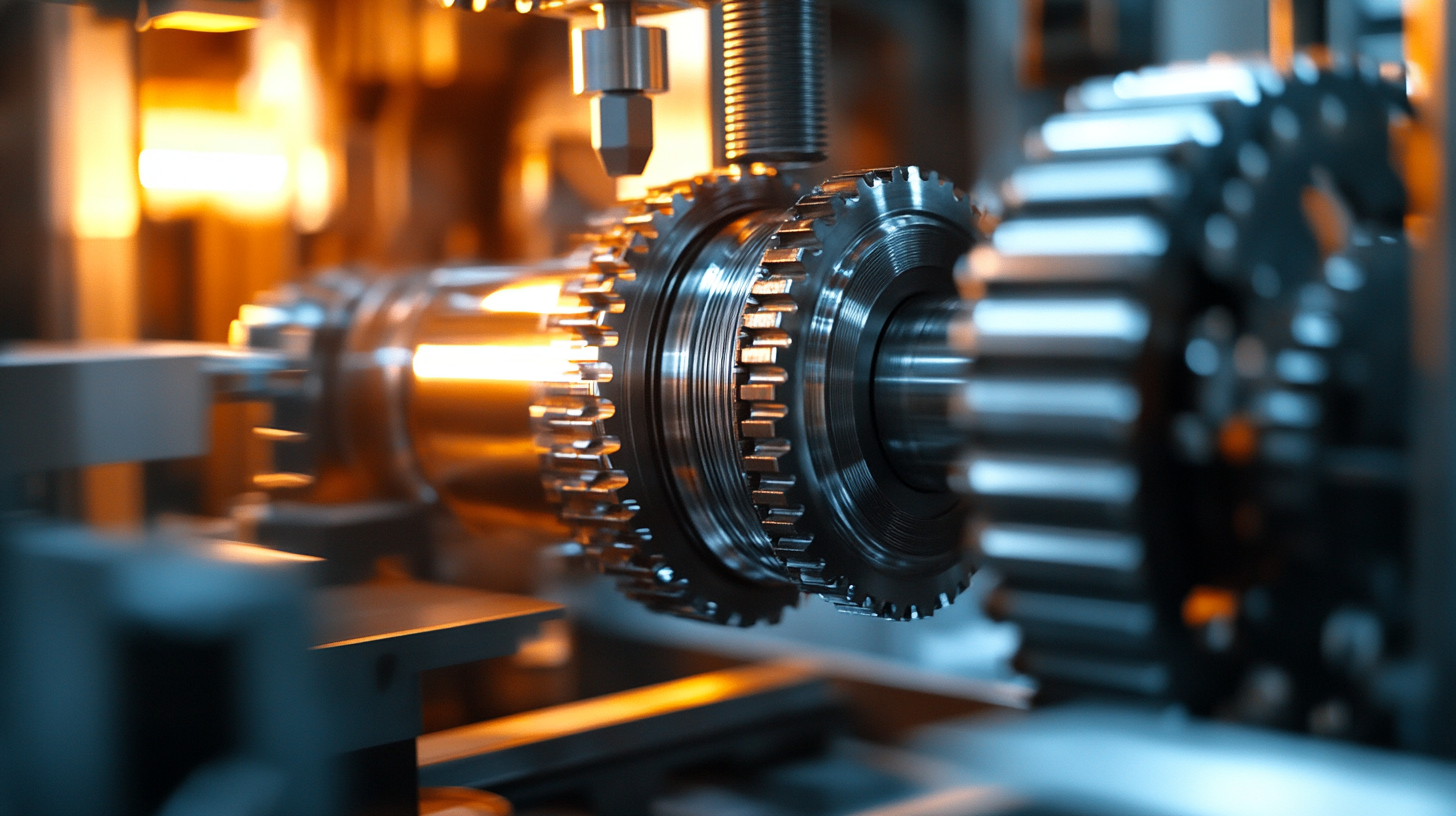

Bonfiglioli planetary gearboxes have emerged as a vital component in enhancing operational efficiency across various industrial sectors. With their innovative design, these gearboxes provide an impressive torque density, which is critical for applications such as robotics, conveyors, and heavy machinery. According to industry reports, the integration of high-performance gear units like those from Bonfiglioli can improve energy efficiency by up to 30%, significantly reducing operational costs for manufacturers. This is particularly crucial in a time when industries are continuously seeking ways to optimize performance while minimizing energy consumption.

One of the key features of Bonfiglioli gearboxes is their compact configuration, which allows for space-saving installations without compromising on output power. This is particularly beneficial in industries where space is at a premium. Additionally, their robust construction ensures longevity under high-stress conditions, ultimately leading to lower maintenance costs and reduced downtime. A 2023 market analysis indicated that companies utilizing advanced gearbox systems such as Bonfiglioli's could experience up to a 25% decrease in maintenance interventions, reinforcing the economic advantages of these gearboxes in operational settings. The combination of efficiency, durability, and space optimization positions Bonfiglioli as a leader in the gearbox market, dramatically transforming industrial operations worldwide.

Unlocking Efficiency: Key Features of Bonfiglioli Gearboxes

Case Studies: Success Stories of Bonfiglioli Gearboxes in Action

Bonfiglioli gearboxes have been at the forefront of transforming industrial operations globally, and the success stories speak volumes about their efficiency and reliability. In one remarkable case, a leading automotive manufacturer faced production delays due to inadequate power transmission systems. By integrating Bonfiglioli planetary gearboxes, they not only streamlined their assembly line but also enhanced torque transmission and minimized energy consumption. The result was a 25% increase in productivity, demonstrating the significant impact that these gearboxes can have on modern manufacturing.

Another standout example comes from the renewable energy sector, where a wind farm operator was struggling with the performance of their turbines. After replacing their conventional gear systems with Bonfiglioli planetary gearboxes, the operator experienced improved durability and reduced maintenance costs. This upgrade allowed for greater energy efficiency and a notable 15% increase in energy output. Such case studies illustrate how Bonfiglioli gearboxes are not just a mere component, but a pivotal element in driving operational success across diverse industries.

Unlocking Efficiency with Bonfiglioli Gearboxes

This chart illustrates the various benefits gained from implementing Bonfiglioli planetary gearboxes in industrial settings, highlighting their ability to enhance productivity, reduce downtime, save energy, and provide operational flexibility.

Comparing Bonfiglioli Gearboxes with Traditional Gearbox Solutions

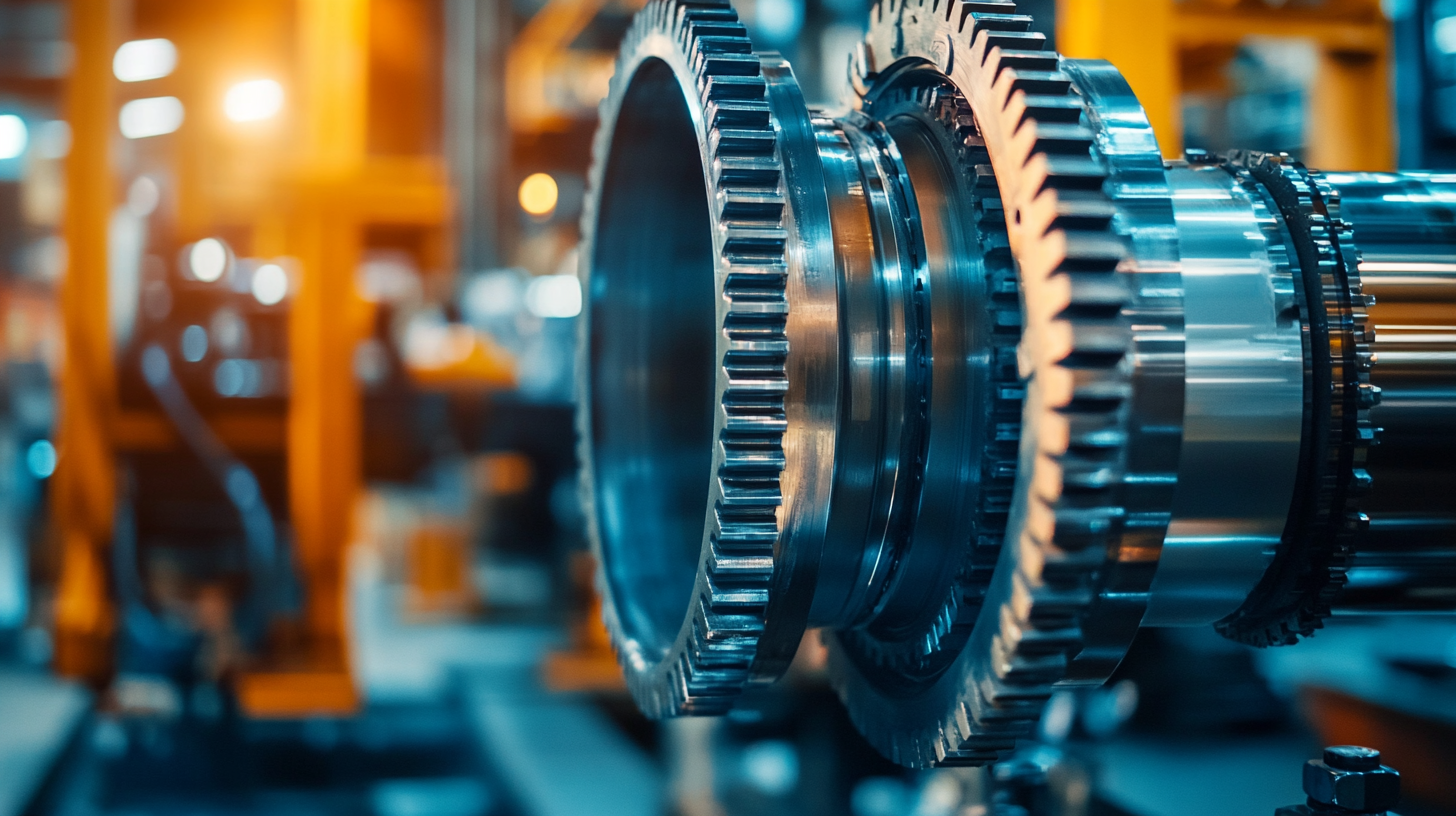

When it comes to industrial operations, the choice of gearbox can significantly influence performance and efficiency. Bonfiglioli planetary gearboxes stand out in this regard, offering advantages that traditional gearbox solutions often cannot match. Unlike standard gearboxes, which typically utilize a simple gear arrangement, Bonfiglioli's design incorporates multiple stages of gear reduction, resulting in a more compact and lightweight solution. This not only maximizes torque transmission but also minimizes energy loss, translating into enhanced operational efficiency.

Moreover, the superior torque density of Bonfiglioli gearboxes enables them to handle heavier loads with ease, reducing the overall footprint of machinery. This is particularly beneficial in industries where space is at a premium. In contrast, traditional gearboxes may require larger housing and more robust components to achieve similar performance, ultimately leading to increased costs and complexities in assembly. Additionally, Bonfiglioli gearboxes feature advanced materials and precision engineering that offer greater durability, even in harsh environments, making them a reliable choice for industrial applications.

By comparing Bonfiglioli gearboxes with conventional options, it becomes clear that the innovative design and engineering of Bonfiglioli products are paving the way for a new era of efficiency in industrial operations. Manufacturers looking to optimize their processes can greatly benefit from considering these advanced gearbox solutions, which not only meet but exceed the demands of modern industry.

Future Trends: The Next Generation of Gear Technology in Industry

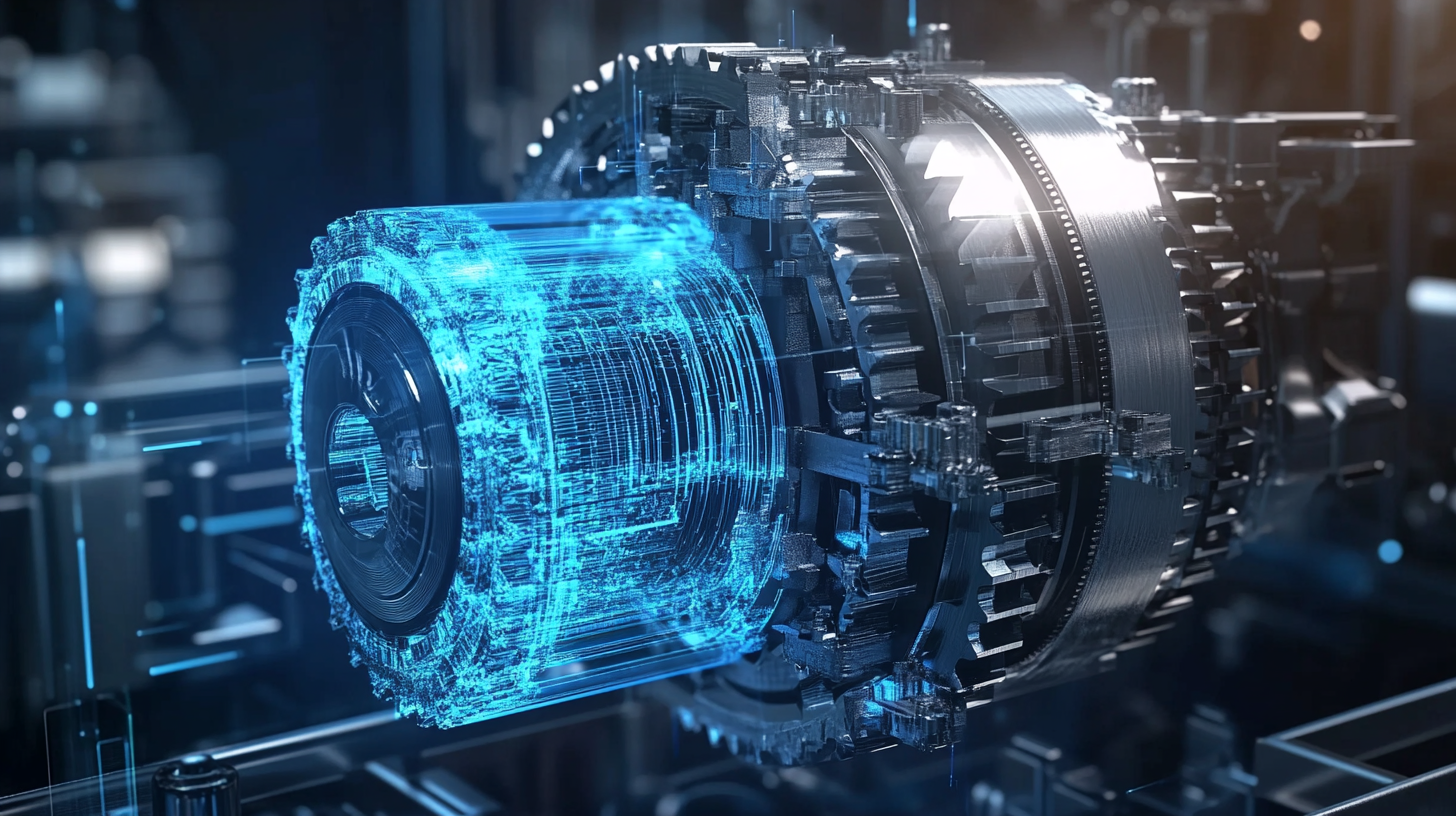

The future of gear technology in the industrial sector is shaping up to be more advanced and efficient than ever, driven by innovations in design and engineering. The next generation of gear systems, particularly Bonfiglioli planetary gearboxes, are leading the charge with a focus on enhanced performance and reduced energy consumption. These sophisticated gearboxes are engineered to handle higher loads in compact designs, facilitating seamless integration into various applications ranging from manufacturing to renewable energy solutions.

As industries increasingly prioritize sustainability, the demand for gear solutions that minimize environmental impact is escalating. Bonfiglioli is setting the standard with gearboxes that not only boost efficiency but also contribute to lower operational costs and reduced carbon footprints. Advanced materials and smart technologies embedded in these gear systems are paving the way for real-time monitoring and predictive maintenance, ensuring longer lifespans and improved reliability. This transformation signals a significant shift towards smarter, greener operations, positioning businesses to thrive in a competitive landscape that values innovation and environmental responsibility.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor