How to Select the Perfect Worm Gearbox for Maximum Efficiency and Longevity

The selection of a worm gearbox is crucial for ensuring maximum efficiency and longevity in mechanical systems. According to a report by the American Gear Manufacturers Association (AGMA), the proper choice of a gearbox can optimize power transmission and significantly reduce wear, leading to an increase in operational lifespan by up to 30%.

Worm gearboxes are renowned for their ability to provide high torque at low speeds, making them ideal for various applications, from industrial machinery to automotive systems. However, the wrong selection can lead to energy losses, mechanical failure, and costly downtimes.

This article delves into the essential factors to consider when choosing a worm gearbox, including material, gear ratio, and lubrication, all aimed at enhancing performance and durability while meeting specific operational demands.

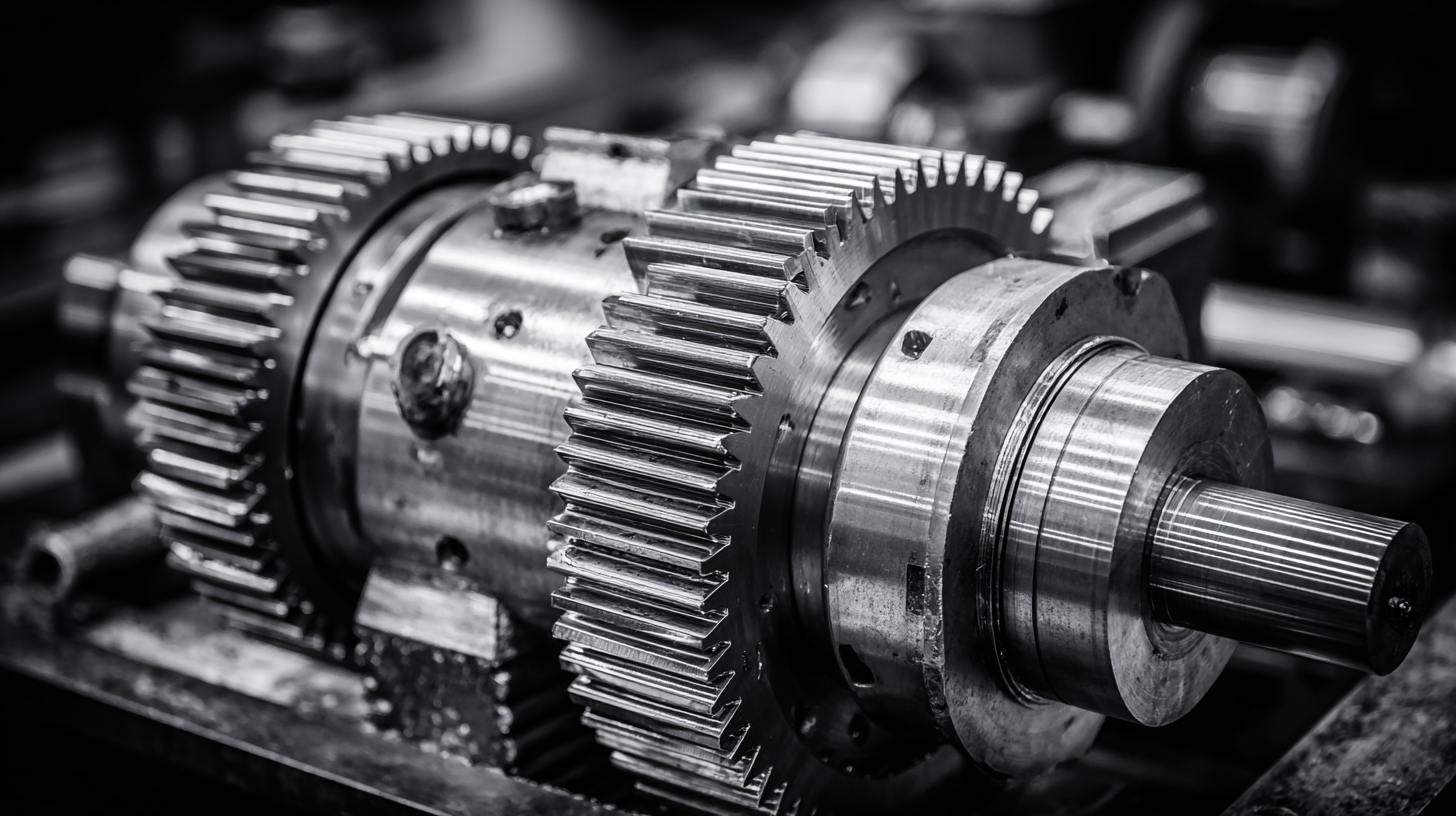

Understanding the Basics of Worm Gearbox Design and Operation Principles

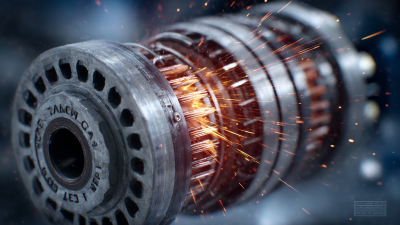

Worm gearboxes are renowned for their unique design and operational principles that contribute to their effectiveness in various applications. At the core of a worm gearbox is a worm screw, which meshes with a worm wheel. This configuration allows for high reduction ratios and compact designs, making them an ideal choice for applications where space is a constraint. The sliding contact between the worm and the wheel generates a high level of friction, which not only reduces efficiency but also generates heat. Understanding this balance of forces is essential for selecting a gearbox that can withstand operational demands without compromising longevity.

Moreover, the lubrication system plays a critical role in enhancing the performance and lifespan of a worm gearbox. Proper lubrication minimizes friction and wear between the contacting surfaces, directly influencing efficiency. It's vital to choose the right lubricant based on the operating conditions, including temperature and load. Additionally, considering the materials used in the construction of both the worm and the wheel helps in preventing premature failure. By grasping these fundamental design and operational principles, users can make informed decisions that lead to optimal performance and durability of worm gearboxes in their applications.

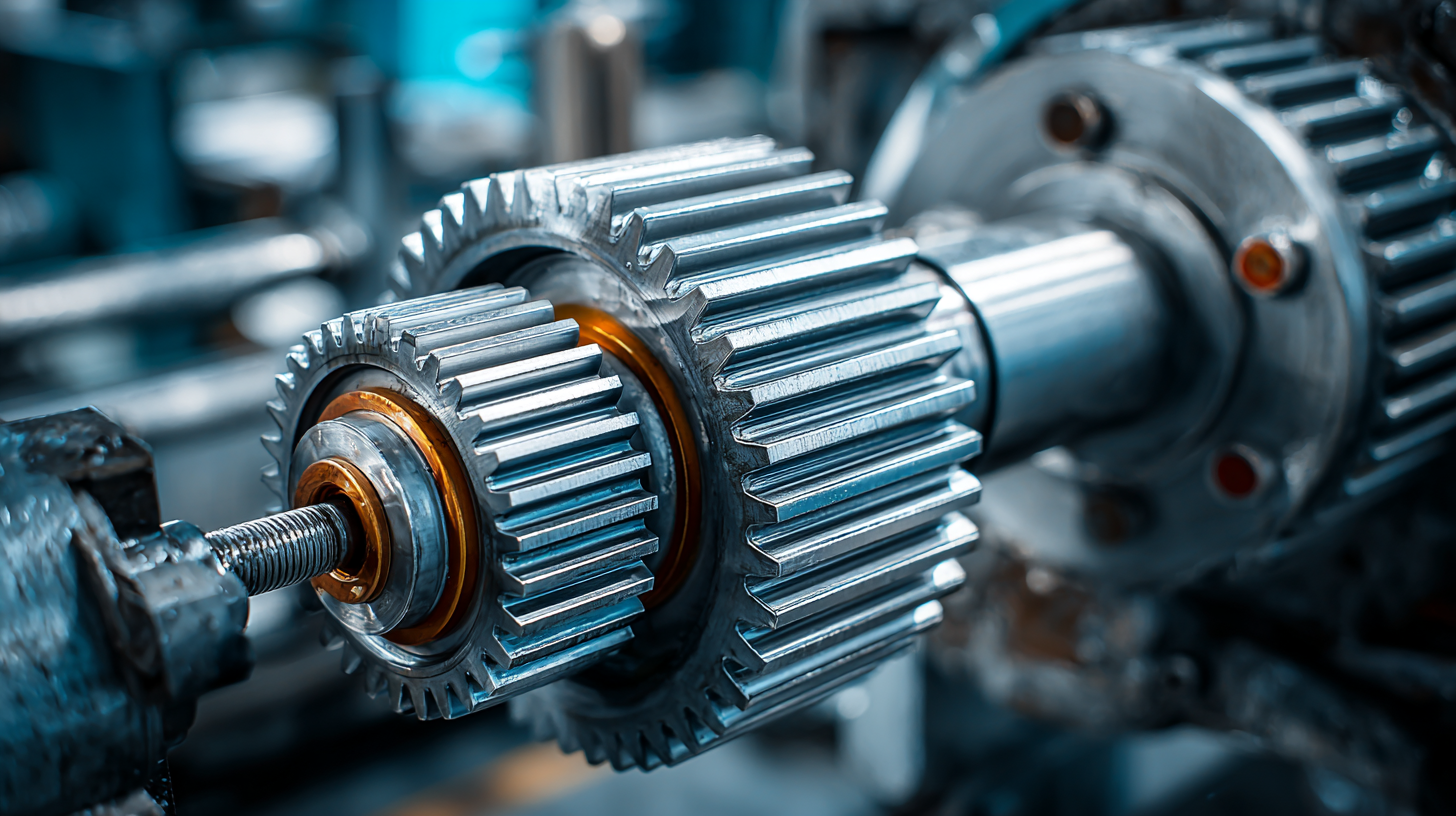

Key Factors Influencing Efficiency in Worm Gearbox Selection

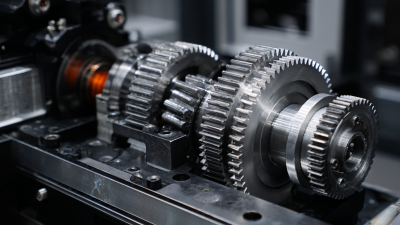

When selecting a worm gearbox for optimal efficiency and longevity, several critical factors come into play. One of the foremost considerations is the

gear ratio, which directly influences the output speed and torque. According to a study by the American Gear Manufacturers Association (AGMA), an optimal gear ratio can enhance torque efficiency by up to 25%, significantly improving the operational capacity of machinery.

Additionally, understanding the load conditions—whether static or dynamical—is essential, as gearboxes rated for higher load capacities tend to have better wear resistance and longevity.

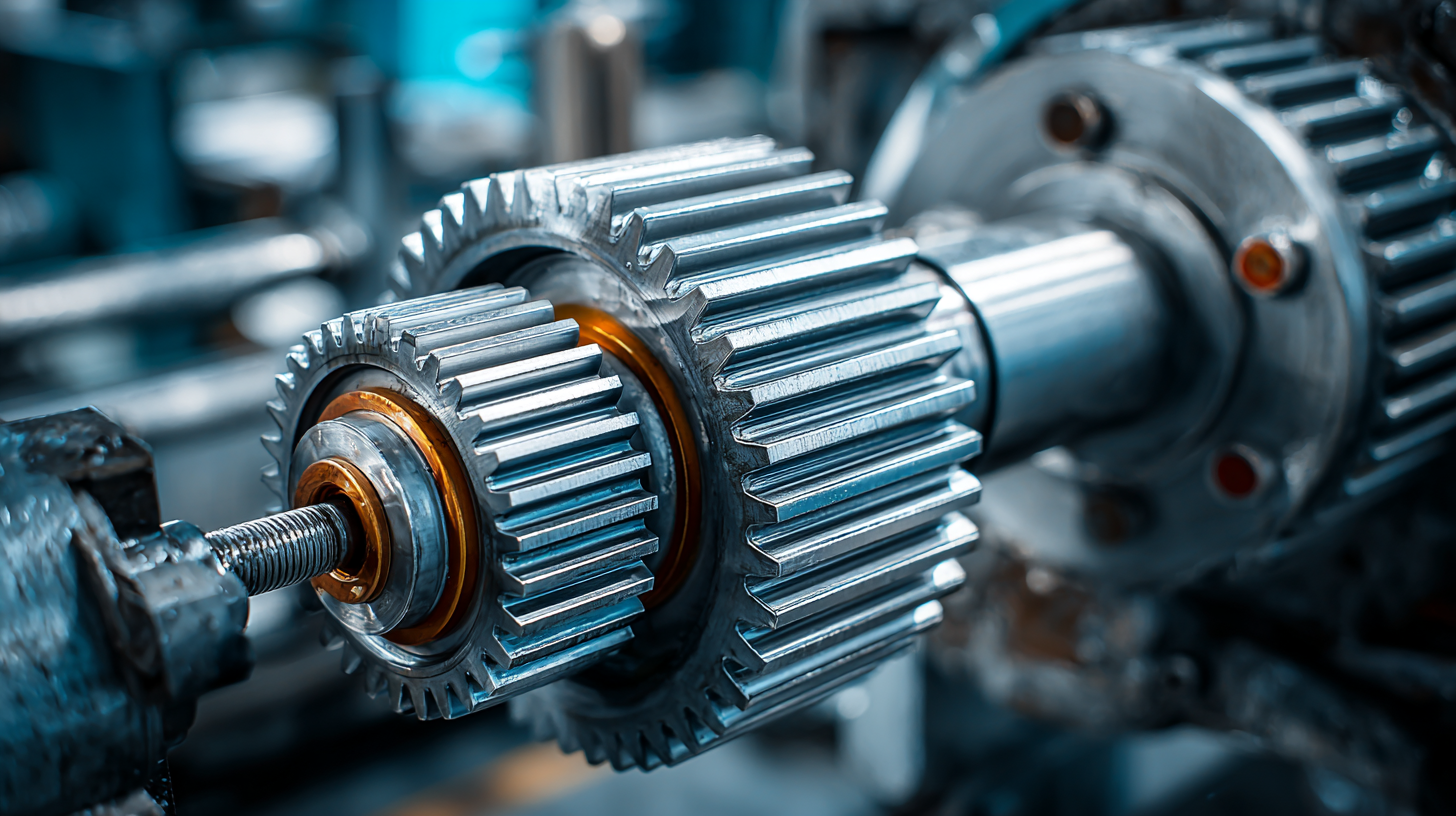

Another vital element is the material selection for both the worm and the wheel. High-quality materials, such as bronze for the gear wheel and case-hardened steel for the worm, can dramatically enhance durability.

Research from the International Journal of Precision Engineering and Manufacturing highlights that using treated materials can reduce wear rates by 30%, thereby prolonging the life of the gearbox.

Furthermore, lubrication type and regular maintenance play a crucial role in maintaining efficiency; improper lubrication can decrease transmission efficiency by up to 15%, making it imperative to use high-quality lubricants and follow recommended maintenance schedules.

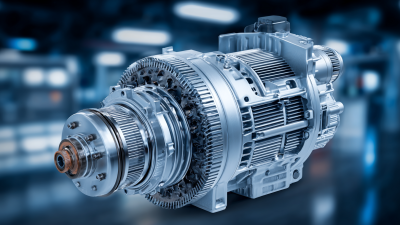

Comparative Analysis of Material Choices for Longevity and Performance

When selecting a worm gearbox, the material used in its construction plays a crucial role in determining both longevity and performance. Common materials include bronze, aluminum, and plastic, each offering distinct advantages.

Bronze, for instance, is renowned for its strength and wear resistance, making it ideal for high-load applications where durability is essential. Its self-lubricating properties also contribute to efficient operation, reducing the need for frequent maintenance.

On the other hand, aluminum provides a lightweight and corrosion-resistant alternative. This material is particularly advantageous in applications where weight reduction is critical, such as in automotive or aerospace sectors. While it may not have the same load-bearing capacity as bronze, advancements in aluminum alloys have improved its performance, making it suitable for medium-load applications.

Additionally, plastics offer a cost-effective and lightweight solution for less demanding environments, but their suitability must be assessed carefully against the operational requirements.

Ultimately, understanding the specific demands of your application is key to making an informed material choice. Each option presents its own benefits and limitations, influenced by factors such as load requirements, environmental conditions, and desired lifespan of the gearbox. Selecting the right material will not only enhance the efficiency of the gearbox but also ensure its longevity over time.

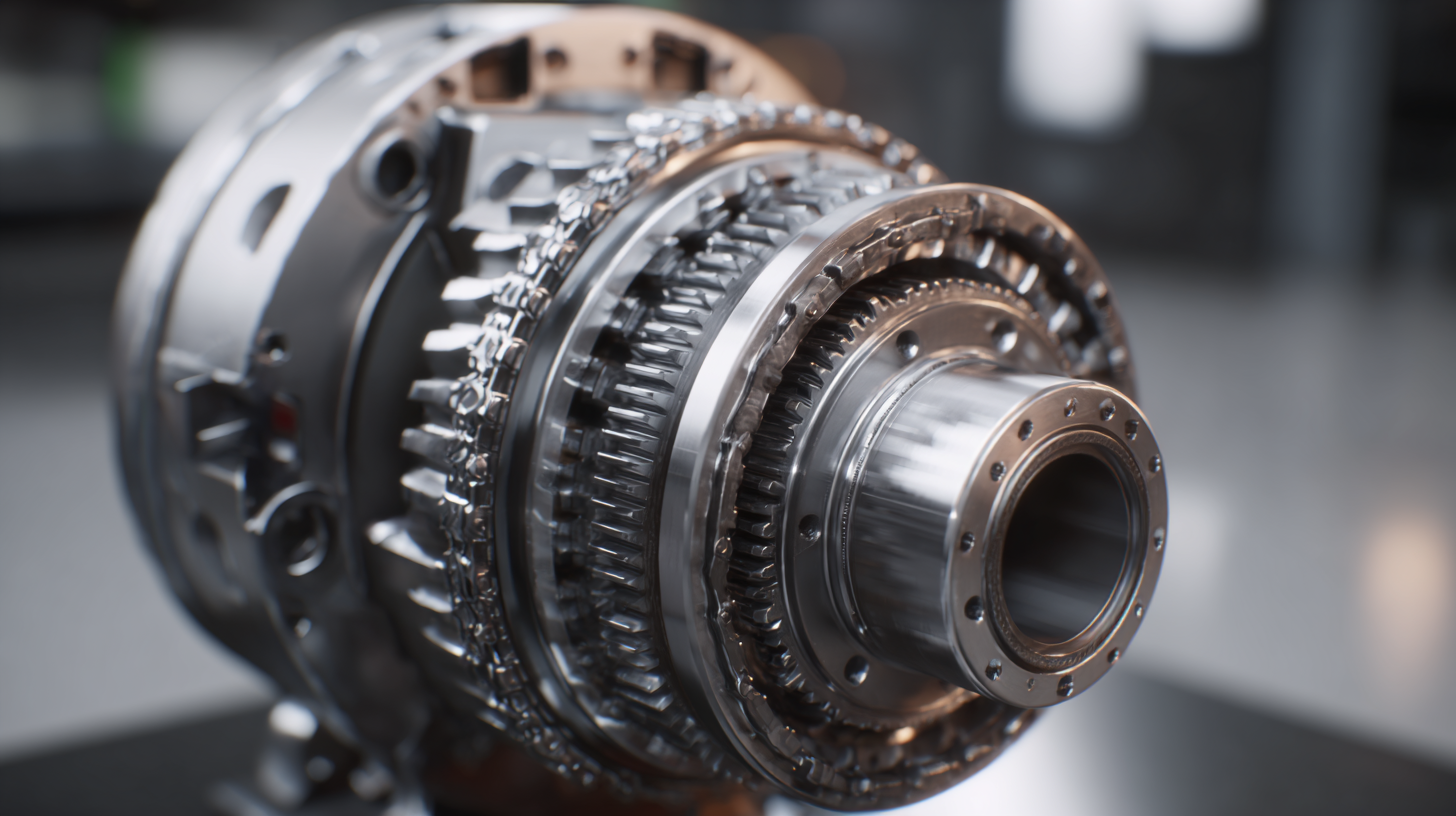

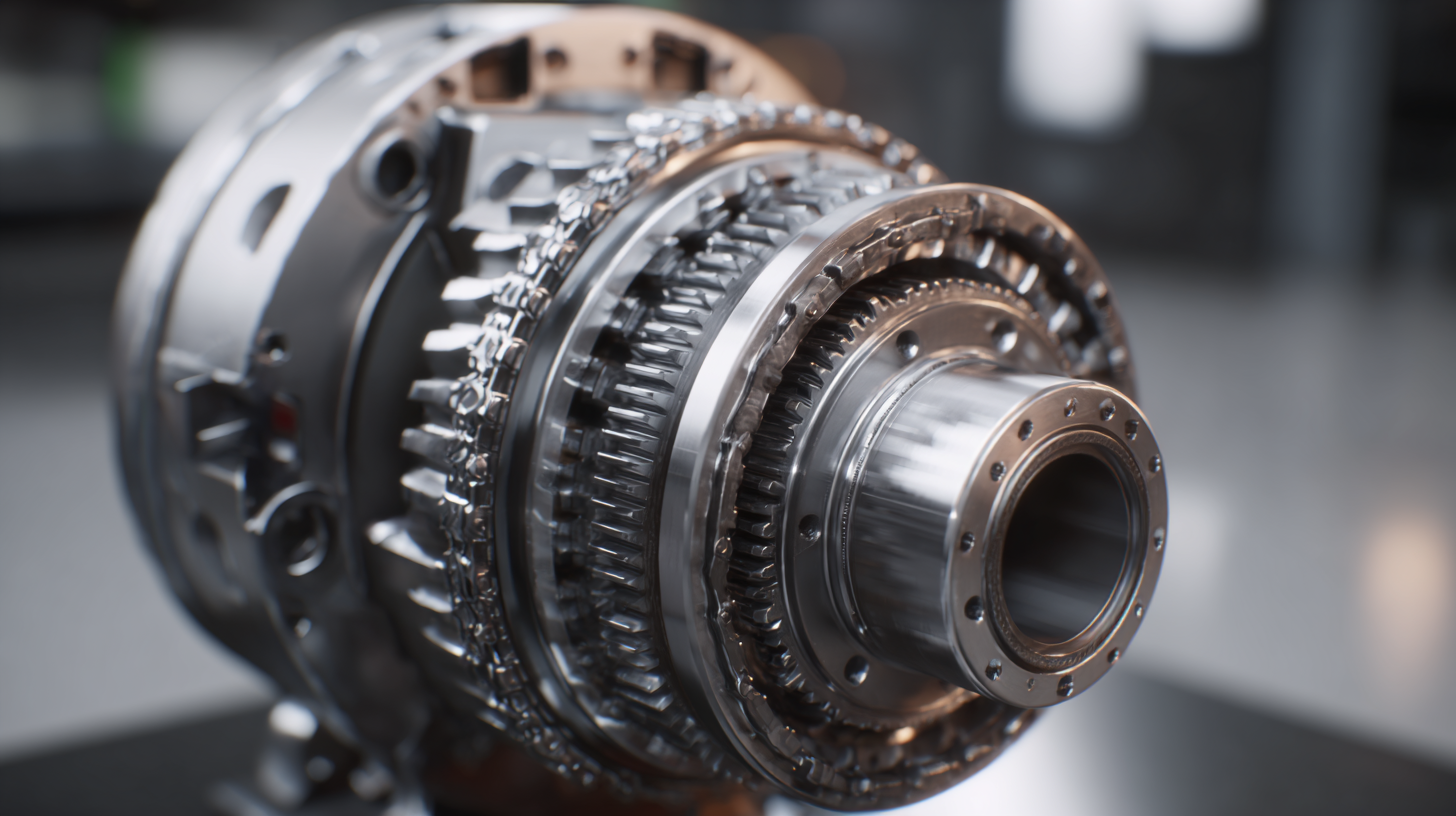

Calculating Load Capacity and Torque Requirements for Optimal Gearbox Selection

Selecting the right worm gearbox is crucial for ensuring optimal performance and longevity in industrial applications. A key aspect of this selection process is accurately calculating the load capacity and torque requirements. According to a report by the American Gear Manufacturers Association (AGMA), determining the correct load capacity is essential because underestimating it can lead to premature gearbox failure. For example, if the torque requirement exceeds the gearbox's rated capacity by just 15%, it can reduce the operational life of the gearbox by up to 50%.

To compute torque requirements effectively, it's important to consider both static and dynamic loads. A study from the International Journal of Engineering Research suggests that employing a safety factor is imperative; a common practice is to utilize a factor between 1.5 to 2.0, depending on application-specific variables such as load cycles and environmental conditions. In many cases, operational conditions like high temperatures or variable loads necessitate a reevaluation of the gearbox specifications. By accurately determining load capacity and adapting to the torque requirements, engineers can select a worm gearbox that not only meets current demands but also enhances the overall efficiency and longevity of the machinery.

Maintenance Best Practices to Enhance the Lifespan of Worm Gearboxes

Worm gearboxes are essential in various industrial applications, renowned for their efficiency and compact design. However, without proper maintenance, their longevity can be significantly compromised. According to a report by the American Gear Manufacturers Association, regular maintenance can extend the lifespan of worm gearboxes by up to 30%. Key practices include ensuring proper lubrication, monitoring operating temperatures, and regularly inspecting for wear and tear. Maintaining optimal lubrication levels not only reduces friction but also dissipates heat, crucial for preventing premature failure.

Tips for Effective Maintenance:

- Always use the manufacturer-recommended lubricant type and change it at specified intervals to ensure optimal performance.

- Implement a routine inspection schedule to check for signs of wear, such as unusual noises or vibrations, which can indicate underlying issues that need attention.

- Maintain proper alignment and mounting, as misalignments can lead to increased stress and accelerated wear on the gearbox.

Adhering to these best practices not only enhances the efficiency of worm gearboxes but also contributes to their sustained operational effectiveness, ensuring they continue to perform at their best over time.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor