Top 10 Geared Servomotors for Precision Motion Control in 2023

In 2023, the demand for precision motion control systems has surged, leading to an increased interest in geared servomotors. These advanced devices are essential for a variety of applications, ranging from robotics to automated manufacturing, where accurate movement is critical. According to Dr. Alice Thompson, a leading expert in the field of automation, "The integration of geared servomotors into motion control systems elevates performance by providing higher torque and improved responsiveness, which are vital for modern industrial tasks."

As industries continue to evolve, the need for superior motion solutions has never been more pronounced. Geared servomotors are designed to meet these challenges, offering enhanced control, reliability, and efficiency. Their unique construction allows for the optimal balance between speed and force, making them indispensable in scenarios that require precise positioning and repeatability. This introduction delves into the top 10 geared servomotors available this year, highlighting their features and applications to inform engineers and decision-makers as they navigate the complexities of motion control technologies.

Overview of Geared Servomotors and Their Applications

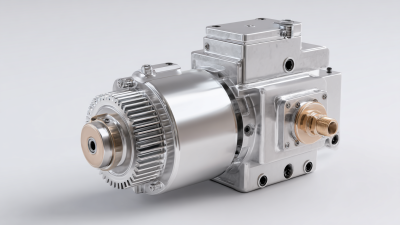

Geared servomotors are pivotal for achieving high-precision motion control in various applications across multiple industries. These devices integrate a motor with a gearbox, allowing for the conversion of high-speed rotation into high-torque output with exceptional accuracy. Their inherent design provides a significant mechanical advantage, enabling fine control over position, speed, and torque, making them ideal for tasks that require meticulous movements, such as robotics, CNC machinery, and automated assembly lines.

The applications of geared servomotors are vast and diverse. In the aerospace sector, they are utilized in flight control systems to ensure precise maneuvers. In medical technology, these motors drive surgical robots that rely on exacting movements for successful procedures. Additionally, in the entertainment industry, geared servomotors are employed in animatronics and motion simulators, where coordinated and fluid animations are critical. As industries continue to adopt automation and smart technology, the demand for reliable and efficient geared servomotors is expected to rise, highlighting their importance in contemporary engineering and manufacturing landscapes.

Key Factors to Consider When Selecting a Geared Servomotor

When selecting a geared servomotor for precision motion control, several key factors should be considered to ensure optimal performance and reliability. First and foremost, the torque rating of the servomotor is critical, as it directly affects the motor's ability to handle the required load. Understanding the application's specific torque requirements, including both static and dynamic loads, will help in choosing a motor that not only meets but exceeds these demands. Additionally, the gearing ratio plays a significant role in determining the output speed and torque characteristics, making it essential to match the geared servomotor's specifications with the application's performance criteria.

Another important consideration is the motor's response time and accuracy, which are vital traits in precision applications. A servomotor with a high-resolution encoder can provide enhanced feedback, allowing for finer control over motion and positioning. Furthermore, environmental factors such as temperature, humidity, and exposure to contaminants should also be taken into account, as these can significantly impact the motor's longevity and efficiency. By evaluating these aspects effectively, one can select a geared servomotor that not only fits the operational requirements but also promotes durability and precision in motion control tasks.

Top 10 Geared Servomotors for Precision Motion Control in 2023

In 2023, the demand for precision motion control systems has surged across various industries, from robotics to automated manufacturing systems. Geared servomotors have emerged as essential components in this evolution, providing the necessary torque and positioning accuracy. A recent industry report indicates that the global market for geared servomotors is projected to reach $7.5 billion by 2025, growing at a CAGR of 6.2%. This growth is driven by the increasing need for efficient motion control solutions that can enhance performance while reducing energy consumption.

The leading characteristics of geared servomotors include high efficiency, compactness, and the ability to sustain heavy loads with remarkable precision. When evaluating these motors, factors such as gear ratios, response time, and thermal management play critical roles. Industry analysts suggest that gear reduction in servomotors can improve torque output significantly, translating to more efficient energy use in various applications. As outlined in the latest technical papers, advancements in materials and design methodologies have allowed manufacturers to optimize their products, ensuring they meet the rigorous demands of modern precision applications. The integration of smart technology within these motors is also taking center stage, allowing for enhanced monitoring and control, thereby pushing the boundaries of precision effectiveness in motion applications.

Comparative Analysis of Performance Features of Leading Models

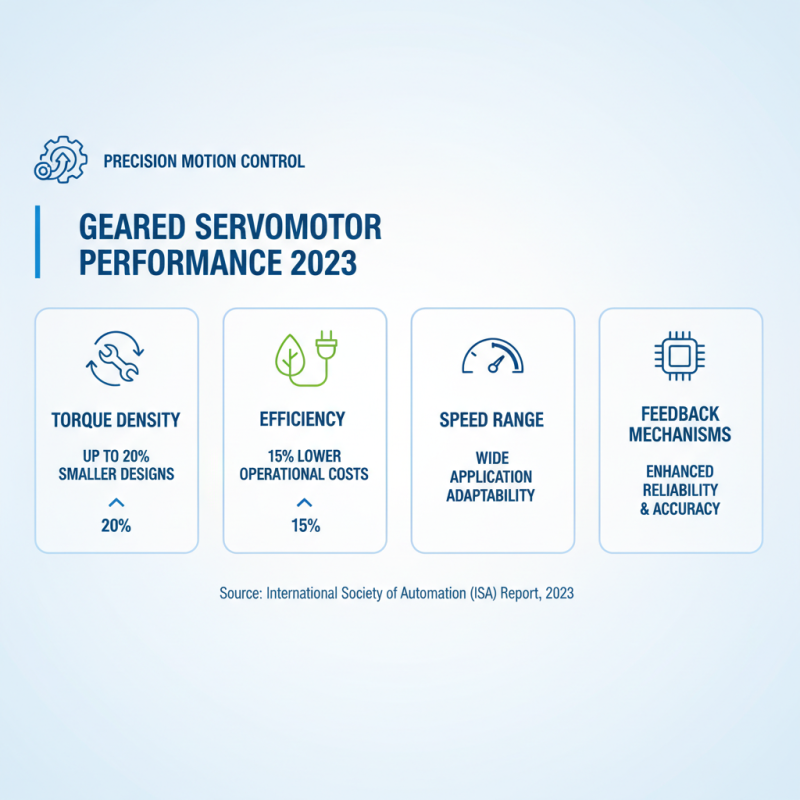

When evaluating geared servomotors for precision motion control in 2023, it is essential to consider various performance features that define their effectiveness in different applications. Key parameters include torque density, efficiency, speed range, and feedback mechanisms. According to the International Society of Automation (ISA) report, precision servomotors have improved torque density by up to 20% compared to previous generations, allowing for smaller designs without compromising on performance. Additionally, efficiency levels have seen enhancements of approximately 15%, translating to lower operational costs and increased reliability over extended periods of use.

Another significant aspect to analyze is the speed range and responsiveness of these servomotors. Recent studies indicate that modern models now achieve speeds of up to 6000 RPM while maintaining exceptional accuracy, a crucial factor in fields such as robotics and CNC machinery. The implementation of advanced feedback systems, like absolute encoders, has also led to a noticeable reduction in lag time, enhancing the overall responsiveness of the motors. The 2022 Motion Control Industry Survey noted that manufacturers are prioritizing integrated feedback solutions, with 75% of respondents considering them critical for future developments in servo technology. Such innovations not only ensure greater precision in motion control but also extend the versatility of applications across various sectors, from manufacturing to aerospace.

Future Trends in Geared Servomotor Technologies and Innovations

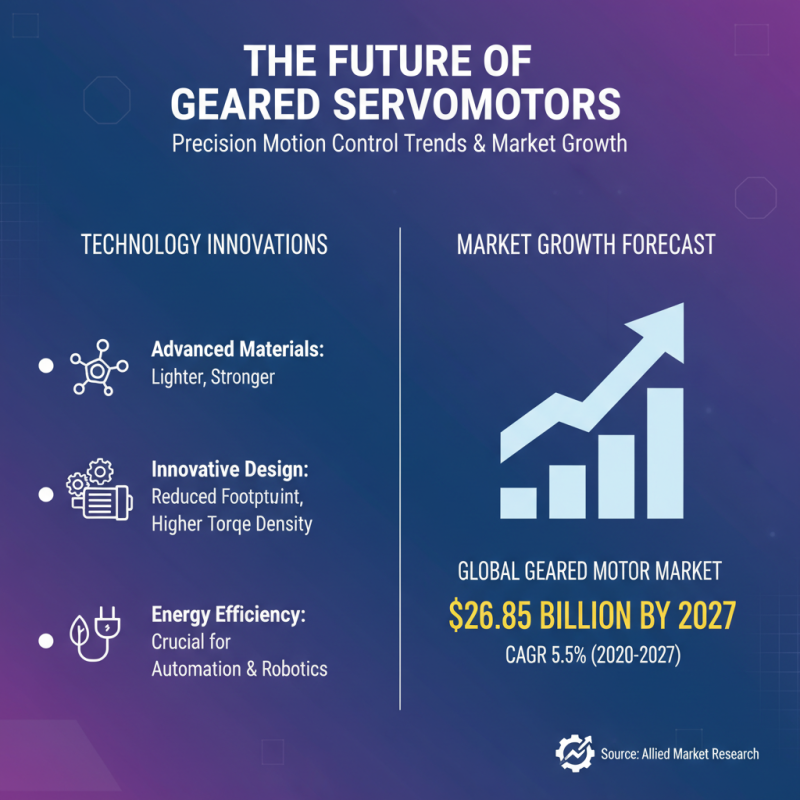

As we look toward the future of geared servomotor technologies, several key trends are poised to reshape the landscape of precision motion control. Notably, manufacturers are making significant strides in integrating advanced materials and innovative design techniques. These improvements are resulting in lighter, more efficient servomotors that offer enhanced torque density and reduced footprint. According to a recent report by Allied Market Research, the global geared motor market is expected to reach $26.85 billion by 2027, with a compound annual growth rate (CAGR) of 5.5%. This growth is driven largely by the demand for energy-efficient solutions in automation and robotics.

Furthermore, the incorporation of smart technology into geared servomotors is gaining traction. With the rise of Industry 4.0, smart servomotors equipped with IoT capabilities are becoming increasingly common. They allow for real-time monitoring and predictive maintenance, which not only increases machine uptime but also enhances overall operational efficiency. A study conducted by the International Federation of Robotics noted that the implementation of smart servomotors in manufacturing sectors could lead to a productivity increase of up to 30%. This trend indicates a transformative shift towards intelligent automation that prioritizes data analytics and connectivity in industrial applications, paving the way for smarter, more adaptable systems in the coming years.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor