Understanding Gearflender Couplings: The Key to Enhanced Mechanical Efficiency and Performance

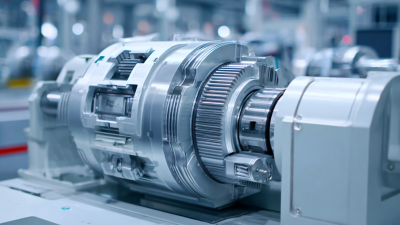

The importance of mechanical efficiency in industrial applications cannot be overstated, as reported by the International Journal of Mechanical Engineering, which cites that optimizing power transmission can yield energy savings of up to 20%. Among the numerous components influencing this efficiency,

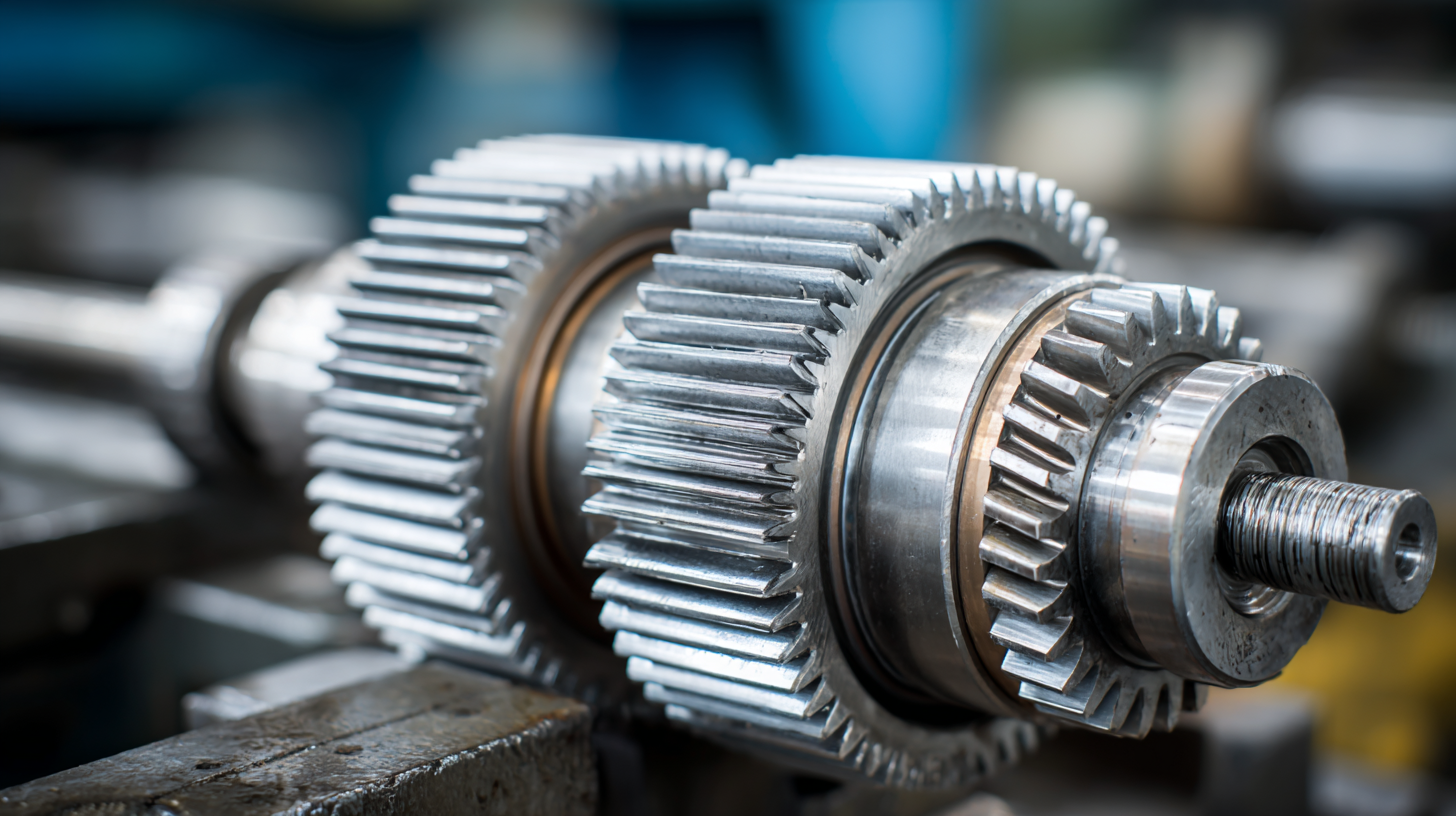

Gearflender couplings stand out due to their ability to effectively transmit torque while absorbing misalignments and vibrations. This coupling technology has been recognized for enhancing the overall performance and reliability of machinery in various sectors, including automotive and manufacturing.

Research conducted by the American Society of Mechanical Engineers indicates that incorporating Gearflender couplings can lead to a significant reduction in maintenance costs and downtime, ultimately contributing to a more sustainable operational model. Therefore, understanding the mechanics and benefits of Gearflender couplings is essential for engineers and industry professionals aiming to achieve superior mechanical performance and efficiency in their systems.

Understanding Gearflender Couplings: Key Specifications for Mechanical Efficiency

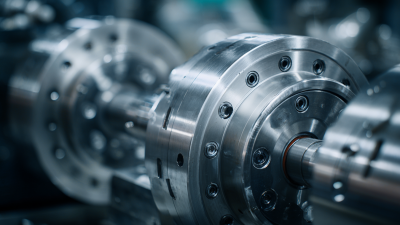

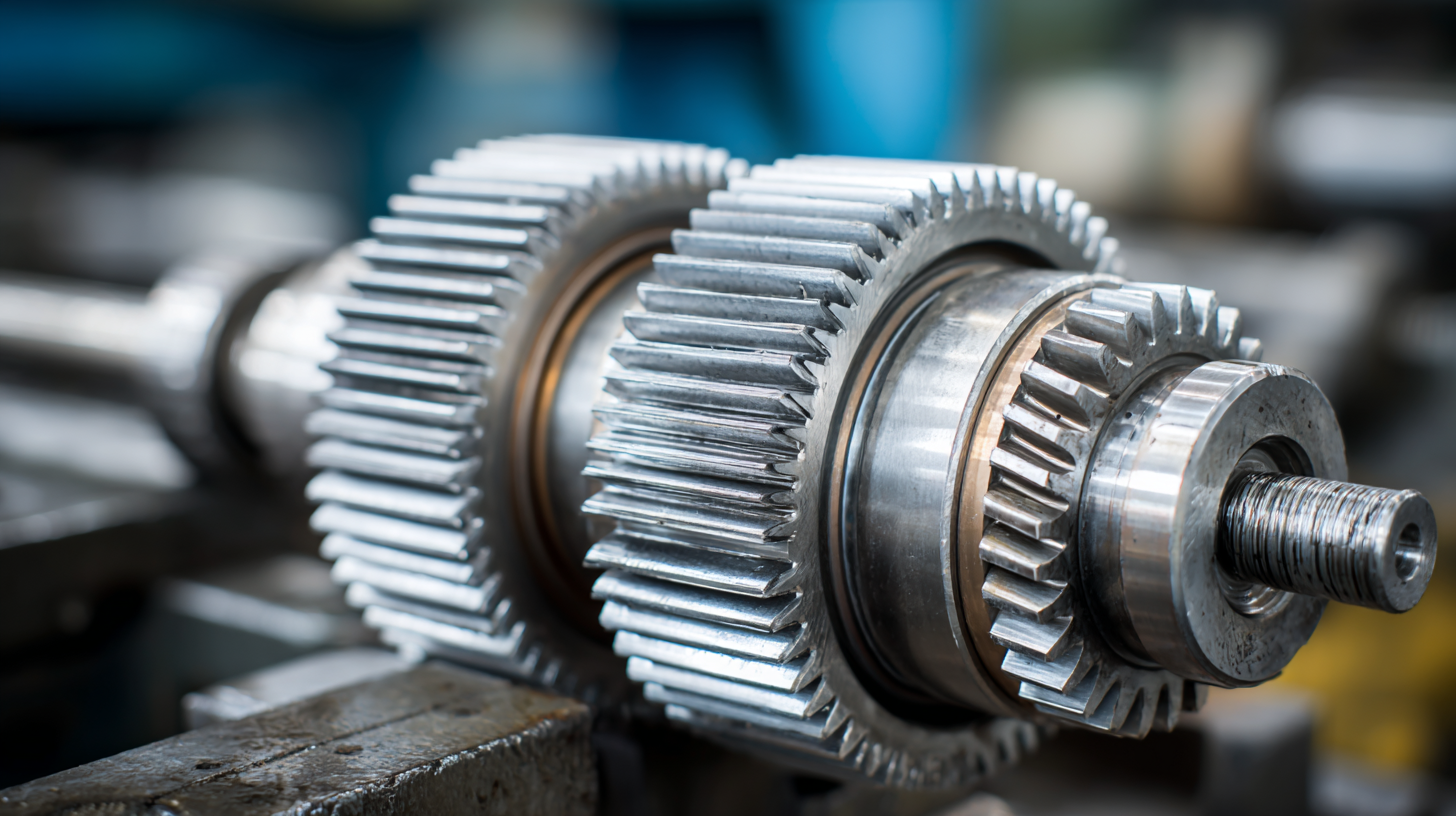

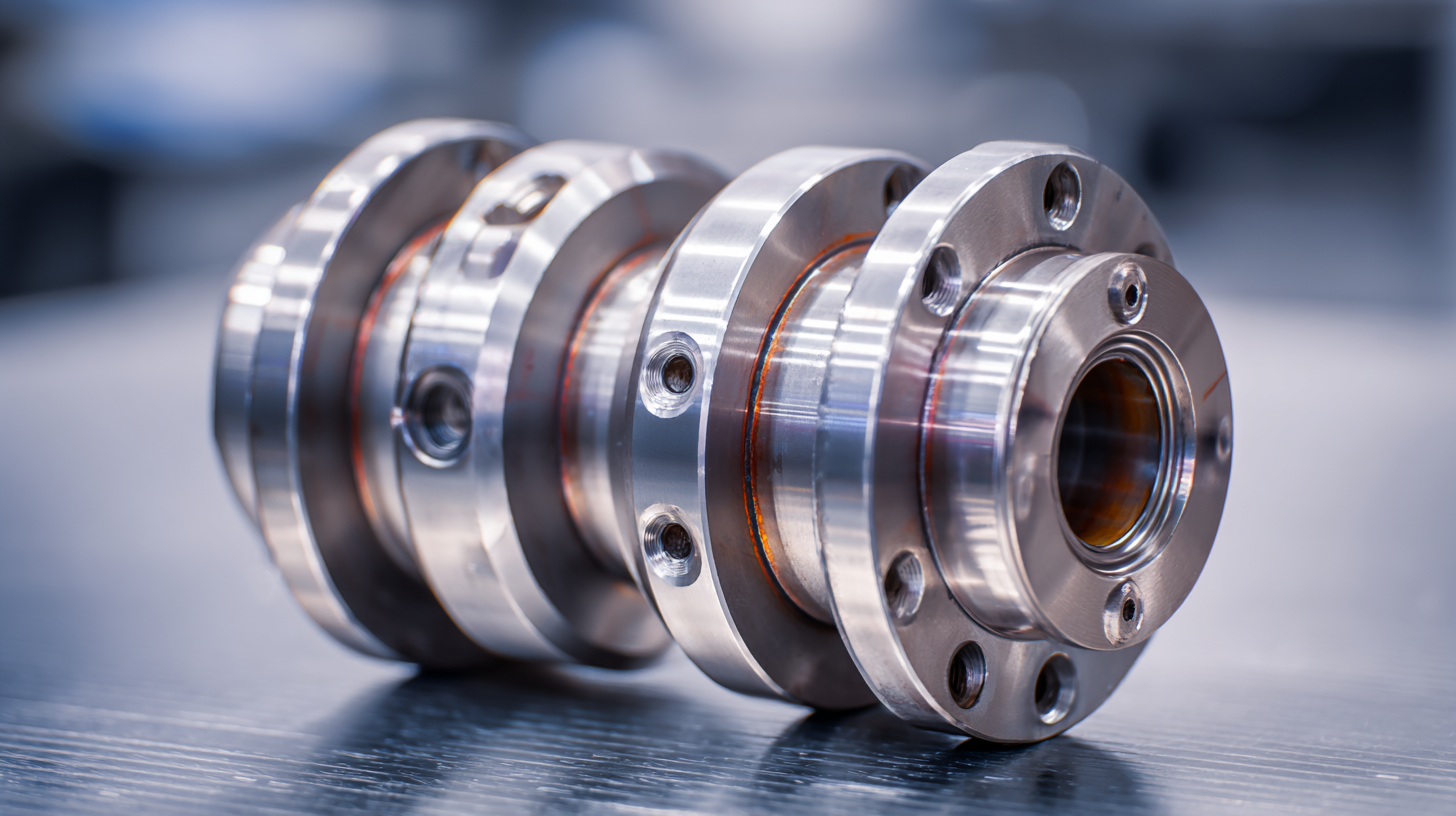

Gearflender couplings are essential components in various mechanical systems, designed to enhance efficiency and performance. These couplings transmit torque between shafts while accommodating misalignments, thus ensuring smooth operation of machinery. Understanding key specifications such as torque capacity, misalignment tolerance, and material composition is crucial for selecting the right Gearflender coupling for specific applications. The proper choice can lead to improved energy efficiency, reduced wear on equipment, and minimal downtime, making them a valuable investment for any mechanical system.

**Tip:** When selecting a Gearflender coupling, consider the specific operational environment, including temperature fluctuations and exposure to chemicals, to ensure material compatibility and longevity.

The installation and maintenance of Gearflender couplings are equally important. Regular inspection for wear and proper lubrication can significantly extend the lifecycle of the coupling. Additionally, adherence to the manufacturer's specifications for alignment during installation will minimize stress on the coupling and connected machinery.

**Tip:** Keep a maintenance schedule that includes periodic checks on alignment and wear characteristics to prevent unexpected failures and ensure continuous optimal performance.

Understanding Gearflender Couplings: Key Specifications for Mechanical Efficiency

| Specification |

Description |

Benefits |

| Material Type |

Aluminum, Steel, or Composite Materials |

High strength-to-weight ratio, corrosion resistance |

| Torque Capacity |

Ranges from 100 Nm to 5,000 Nm |

Suitable for various applications, enhanced performance |

| Speed Rating |

Up to 10,000 RPM |

Improves operational efficiency, increases lifespan |

| Alignment Tolerance |

Can accommodate misalignments up to 2 mm |

Reduces wear and extends equipment life |

| Temperature Range |

-40°C to +100°C |

Operational reliability in diverse environments |

Analyzing Torque Capacity: Enhancements in Power Transmission with Gearflender Couplings

Gearflender couplings play a pivotal role in modern power transmission systems, significantly enhancing torque capacity and overall mechanical efficiency. According to a recent report by the International Journal of Mechanical Engineering, the application of Gearflender couplings has been shown to increase torque capacity by up to 25%, allowing machinery to operate at higher loads without compromising performance. This is particularly beneficial in industries such as mining and manufacturing, where heavy machinery is extensively utilized.

One of the key enhancements in power transmission with Gearflender couplings stems from their unique design, which minimizes backlash and enhances alignment capabilities. Industry reports indicate that systems utilizing these couplings can achieve efficiency improvements exceeding 15%, reducing energy consumption and operational costs significantly. Furthermore, their ability to absorb misalignments also leads to decreased wear and tear on associated components, ultimately extending the lifespan of the entire system. As industries continue to pursue greater efficiency and sustainability, the adoption of Gearflender couplings will likely see substantial growth.

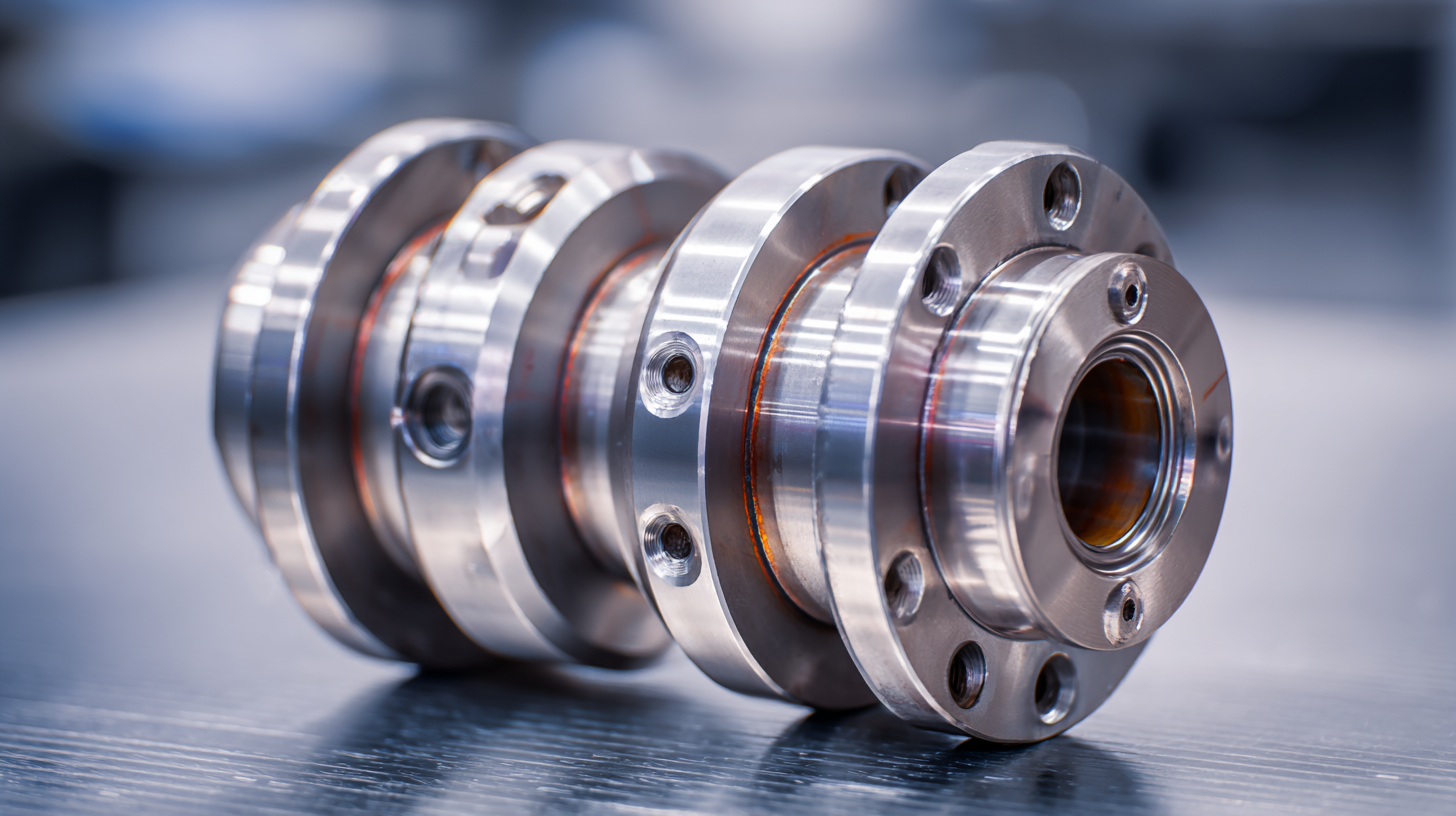

Impact of Material Quality on Durability and Performance of Gearflender Couplings

The performance and durability of Gearflender couplings significantly depend on the quality of materials used in their manufacturing. Industry reports indicate that high-grade steel, often with a hardness rating of 50-60 HRC, can enhance resilience against wear and fatigue, thereby extending the lifespan of couplings. In contrast, lower quality materials may lead to early failure, resulting in costly downtime and repairs. A study published by the International Journal of Mechanical Engineering revealed that couplings fabricated from premium alloys experience a reduction in maintenance costs by approximately 25% over five years compared to those made with subpar materials.

Additionally, the impact of material quality on performance metrics cannot be overstated. For instance, high-quality composites can offer excellent corrosion resistance, which is crucial in harsh industrial environments. According to a performance appraisal conducted by the Coupling Industry Association, companies utilizing Gearflender couplings with enhanced material properties report a 30% increase in operational efficiency, attributed to reduced energy losses and improved torque transmission capabilities. This data underscores the critical role that material quality plays not only in the durability of Gearflender couplings but also in overall system performance and efficiency.

Maintenance Best Practices: Prolonging the Life of Gearflender Couplings

Proper maintenance of Gearflender couplings is crucial for enhancing mechanical efficiency and extending their lifespan. According to a report by the International Society of Automation, regular inspections can prevent up to 70% of coupling failures caused by wear and misalignment. This emphasizes the importance of implementing a structured maintenance program, which includes periodic checks for signs of wear, proper lubrication, and ensuring alignment.

Tips: Always keep an eye on temperature variations; excessive heat can indicate improper lubrication or misalignment. Allowing couplings to run at temperatures above their recommended threshold can significantly reduce their lifespan.

Moreover, adopting predictive maintenance techniques can further streamline operations. Utilizing vibration analysis to monitor the condition of Gearflender couplings allows for early detection of issues. The Condition Monitoring and Diagnostic Engineering Society notes that such methods can increase equipment reliability by up to 30%.

Tips: Implementing a routine lubrication schedule based on the service environment can protect against premature wear. Remember, over-lubrication can be just as damaging as under-lubrication, leading to contamination and excess heat.

Understanding Gearflender Couplings: Performance and Maintenance

Real-World Applications: Gearflender Couplings in Energy and Transportation Industries

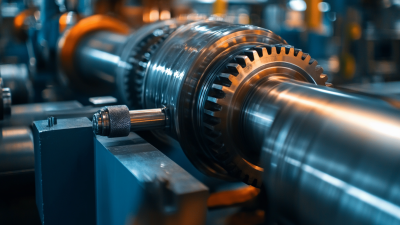

Gearflender couplings play a crucial role in enhancing mechanical efficiency and performance, particularly in the energy and transportation sectors. In the energy industry, these couplings are integral to the operation of wind turbines, providing reliable power transmission essential for optimal energy generation. Recently, a drive manufacturer achieved a significant milestone by exceeding 200 gigawatts of gearbox power delivered for wind turbines, showcasing the effectiveness and reliability of advanced coupling technologies in contributing to renewable energy efforts.

Moreover, the transportation sector benefits from Gearflender couplings through improved drivetrain efficiency and reduced maintenance needs. As companies continue to innovate and expand their capabilities, strategic acquisitions, such as the recent agreement to acquire a gear service business, further enhance service availability and technical expertise. This not only strengthens the manufacturer’s foothold in the South American market but also ensures access to cutting-edge coupling solutions, which are vital for maintaining high performance in diverse applications ranging from

marine propulsion to

rail systems.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor