Understanding the Mechanics Behind Planetary Gearbox Types

In the realm of mechanical engineering, understanding the intricacies of various gearbox types is essential for optimizing performance and efficiency in diverse applications. Among these, the Planetary Gearbox stands out for its remarkable ability to transmit power effectively while maintaining a compact design. This sophisticated mechanism is characterized by its unique arrangement of gears, which allows multiple gear ratios to be achieved in a single system. As industries increasingly seek solutions that offer both high torque and reduced size, the Planetary Gearbox has gained significant attention. This blog will delve into the fundamental mechanics behind different types of planetary gearboxes, exploring their design, functionality, and applications. By examining the "how to" aspects of these gear systems, we aim to provide readers with a comprehensive understanding of why planetary gearboxes are favored in contemporary engineering solutions.

Exploring the Fundamentals of Planetary Gearbox Design: An In-Depth Overview

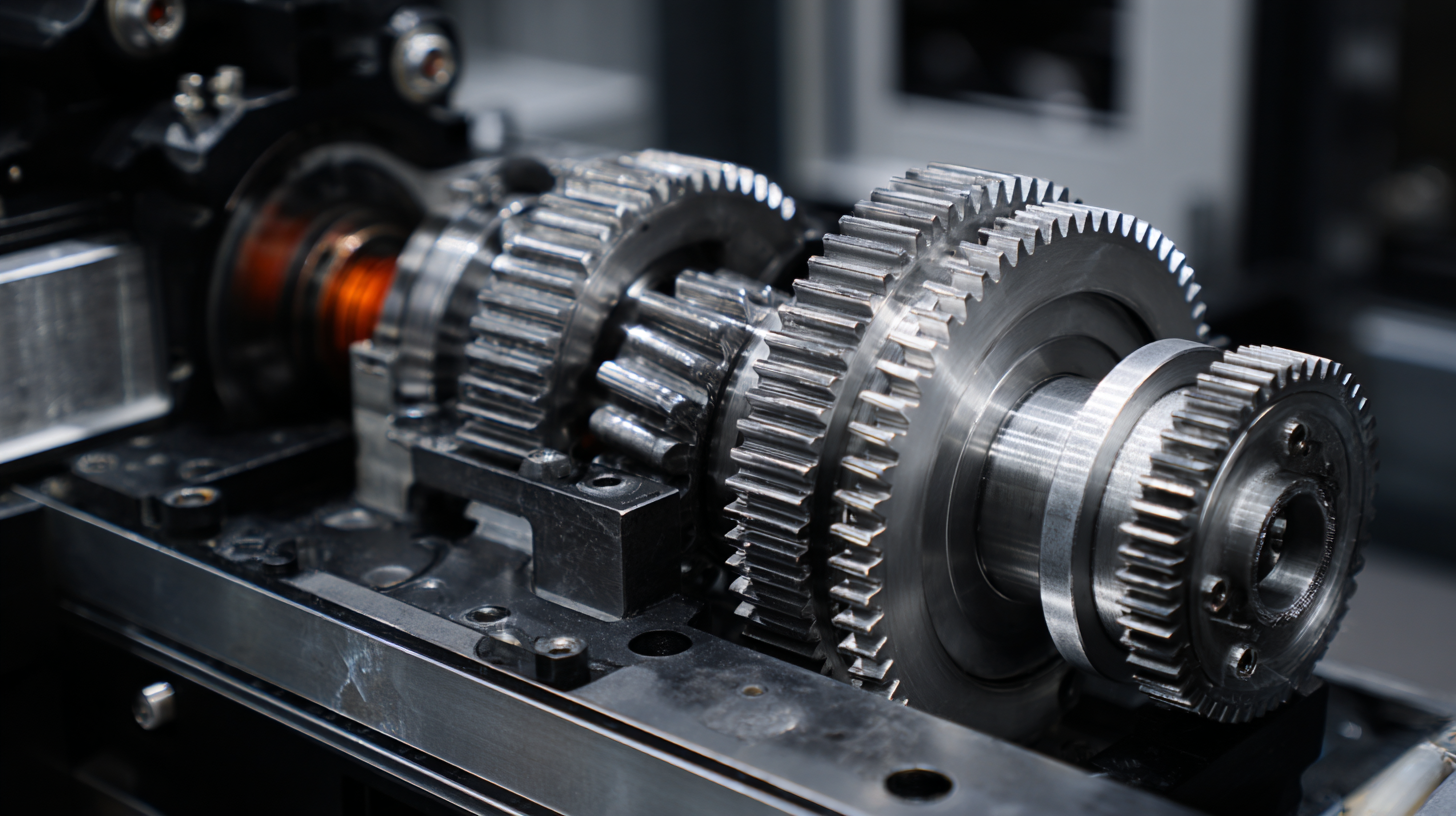

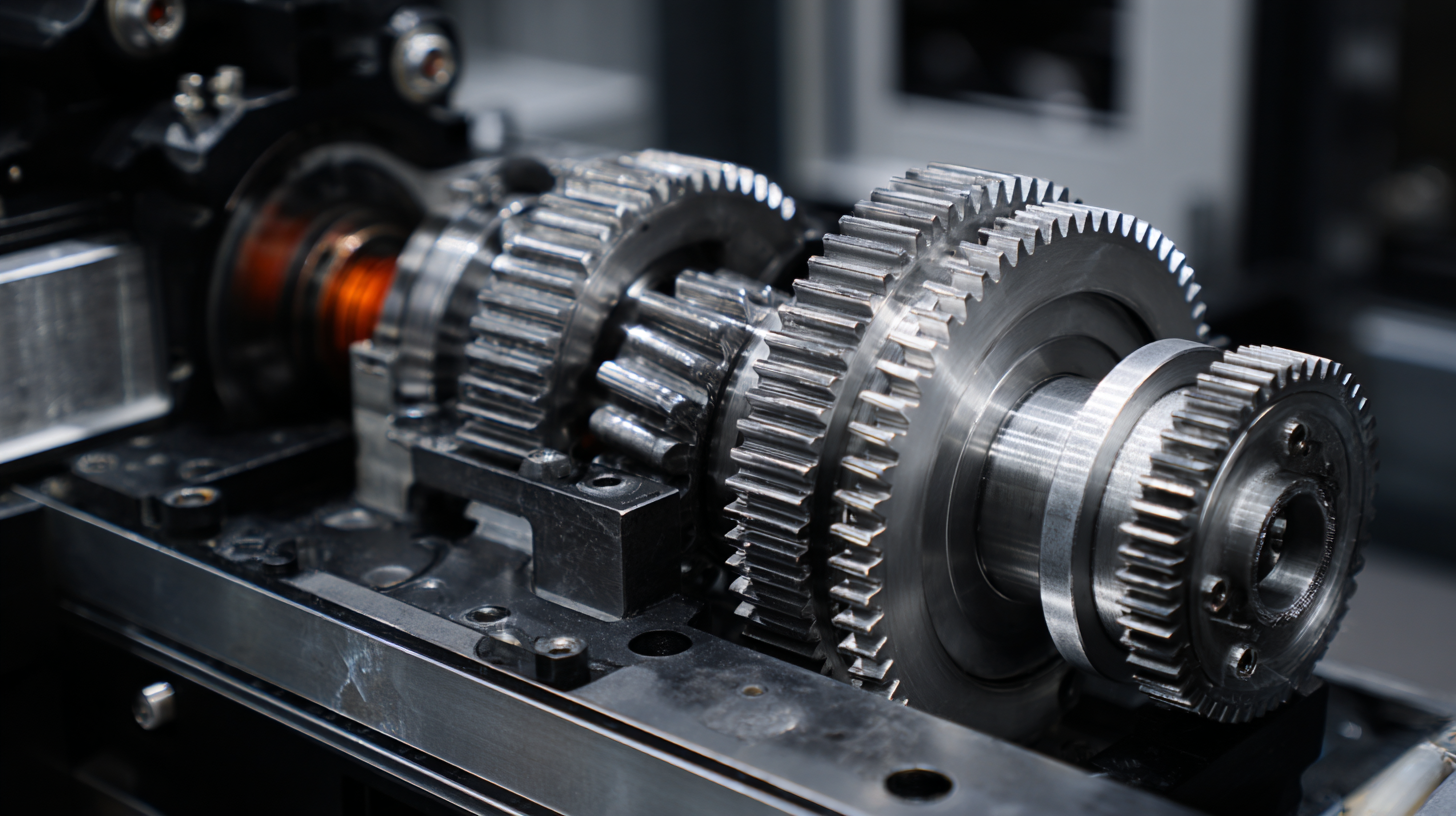

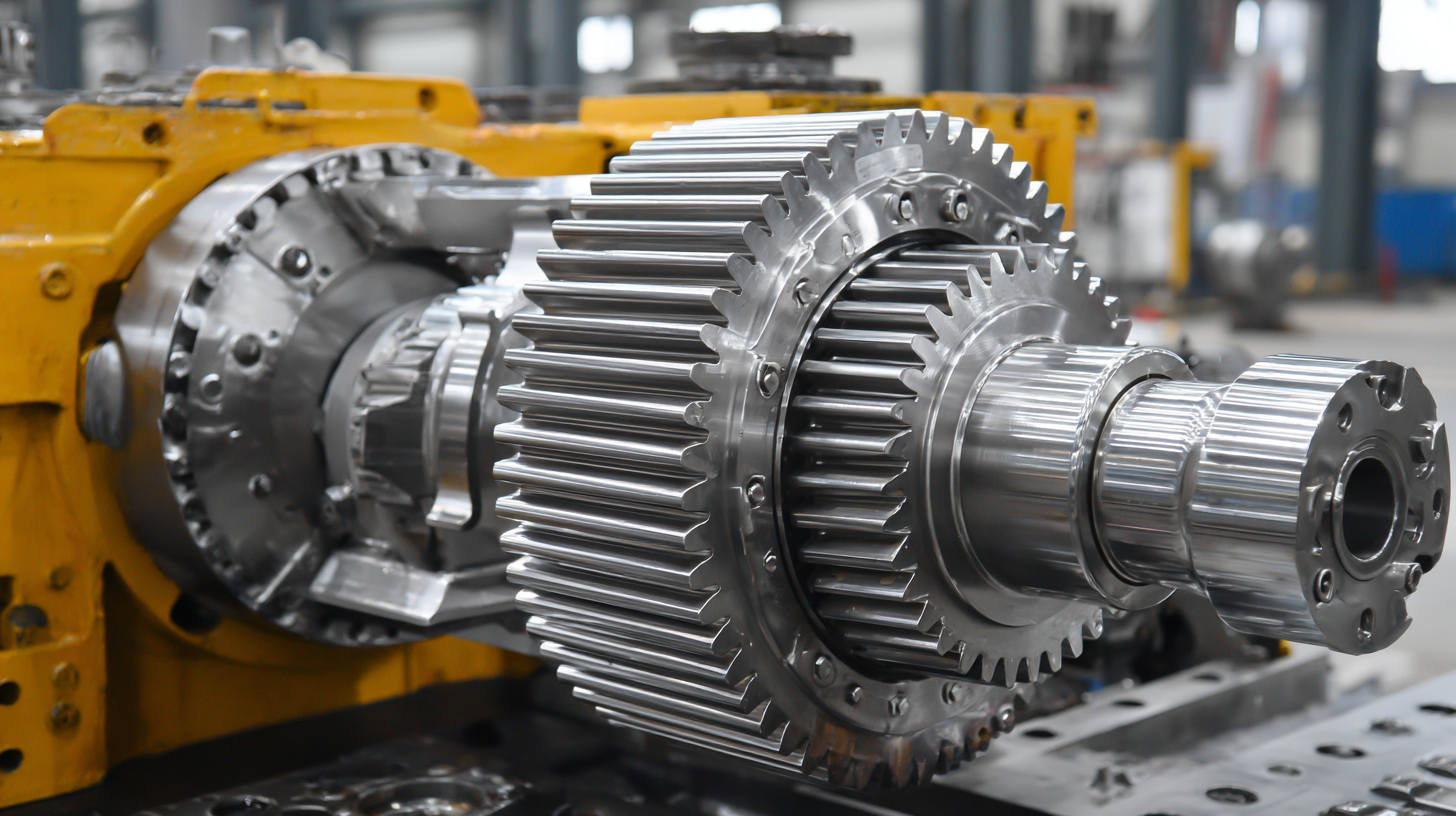

Planetary gearboxes are intricate systems that play a crucial role in various applications, from automotive to industrial machinery. Understanding their design fundamentals is essential for engineers and technicians alike. At the heart of a planetary gearbox is its unique arrangement of gears: the sun gear, planet gears, and the ring gear. This configuration enables compact size and high torque output, making it an ideal choice for applications requiring efficiency and reliability.

When working with planetary gearboxes, it is essential to consider factors such as load capacity, gear ratio, and efficiency. Tip: Always analyze the intended application to select the appropriate gearbox type – whether it's a single-stage or multi-stage system will impact performance and durability. Another critical aspect is lubrication; the right type can significantly affect the gearbox's longevity. Tip: Regularly monitor lubricant levels and quality to prevent overheating and wear.

Additionally, advancements in materials and manufacturing techniques are paving the way for more durable and efficient planetary gearboxes. Understanding these developments can facilitate better design choices and selection processes. Tip: Stay updated with the latest innovations in gearbox technology to enhance your design capabilities and improve overall system performance.

Key Types of Planetary Gearboxes and Their Unique Applications in Industry

Planetary gearboxes play a crucial role in various industrial applications, particularly in the robotics sector. The demand for precision gear systems has seen significant growth, with the market for precision gears and reducers for humanoid robots valued at approximately USD 350.3 million in 2024. This underscores the essential function of planetary gearboxes in enhancing the performance and efficiency of robotic systems across industries such as automotive and electronics. The increasing complexity of tasks performed by industrial robots necessitates advanced gear systems that can provide high torque density and compact designs, making planetary gearboxes a preferred choice.

Recent developments in the gearbox industry highlight the adaptability of planetary gear systems for various applications. Schaeffler's acquisition of a specialized planetary gearbox manufacturer indicates a strategic move to strengthen its robotics portfolio, further enhancing automation capabilities. Additionally, assessments of conventional and emerging gearbox technologies suggest robust performance tailored to human-robot interaction applications, indicating that the gearbox types vary notably in their operational effectiveness depending on the specific application. The projected growth of the automotive gearbox market, anticipated to reach USD 236.69 billion by 2034, illustrates a broader trend in the industry, emphasizing the unique advantages that different types of planetary gearboxes bring to diverse applications.

Understanding the Mechanics Behind Planetary Gearbox Types - Key Types of Planetary Gearboxes and Their Unique Applications in Industry

| Gearbox Type |

Number of Stages |

Torque Capacity (Nm) |

Efficiency (%) |

Common Applications |

| Single-stage |

1 |

100-200 |

95 |

Robotics, Conveyors |

| Double-stage |

2 |

200-400 |

92 |

Automotive, Aerospace |

| Three-stage |

3 |

400-800 |

90 |

Heavy Machinery, Wind Energy |

| Hypoid |

1-3 |

150-600 |

88 |

Bicycle Gearboxes, Electric Drives |

| Custom Designed |

Variable |

100-1000+ |

≥ 85 |

Specialized Industrial Applications |

Efficiency Metrics: Comparing Performance Across Different Gearbox Types

When comparing efficiency metrics across different planetary gearbox types, it's essential to consider how design impacts performance. According to a report by Gear Technology, planetary gear systems can achieve efficiencies ranging from 90% to 97%, depending on the configuration and application type. In contrast, traditional spur gear systems often exhibit lower efficiency, around 80% to 85%. This disparity highlights the importance of selecting the right gearbox type for maximizing operational efficiency.

Efficiency isn't solely about mechanical performance; it also relates to energy consumption and heat generation. A 2021 study published by the International Journal of Engineering Research indicates that planetary gearboxes tend to produce less heat, contributing to higher overall energy efficiency during operation. For instance, a well-designed planetary gearbox can reduce energy losses by as much as 15% compared to other gearbox types under similar load conditions. Such metrics are crucial for industries like automotive and aerospace, where performance and efficiency directly impact operational costs and environmental considerations.

Efficiency Metrics: Comparing Performance Across Different Gearbox Types

This chart compares the efficiency rates of various types of planetary gearboxes based on their design and application. The data illustrates how different configurations can impact performance.

The Role of Load Capacity in Choosing the Right Planetary Gearbox

When selecting a planetary gearbox, one of the most critical factors to consider is load capacity. Load capacity refers to the maximum load that the gearbox can safely handle without compromising performance or causing failure. Understanding this aspect is vital because it directly impacts the efficiency and longevity of your mechanical system. A gearbox under excessive load can lead to increased wear, overheating, and ultimately, premature failure. Thus, it is imperative to choose a gearbox with an adequate load capacity to meet the demands of your application.

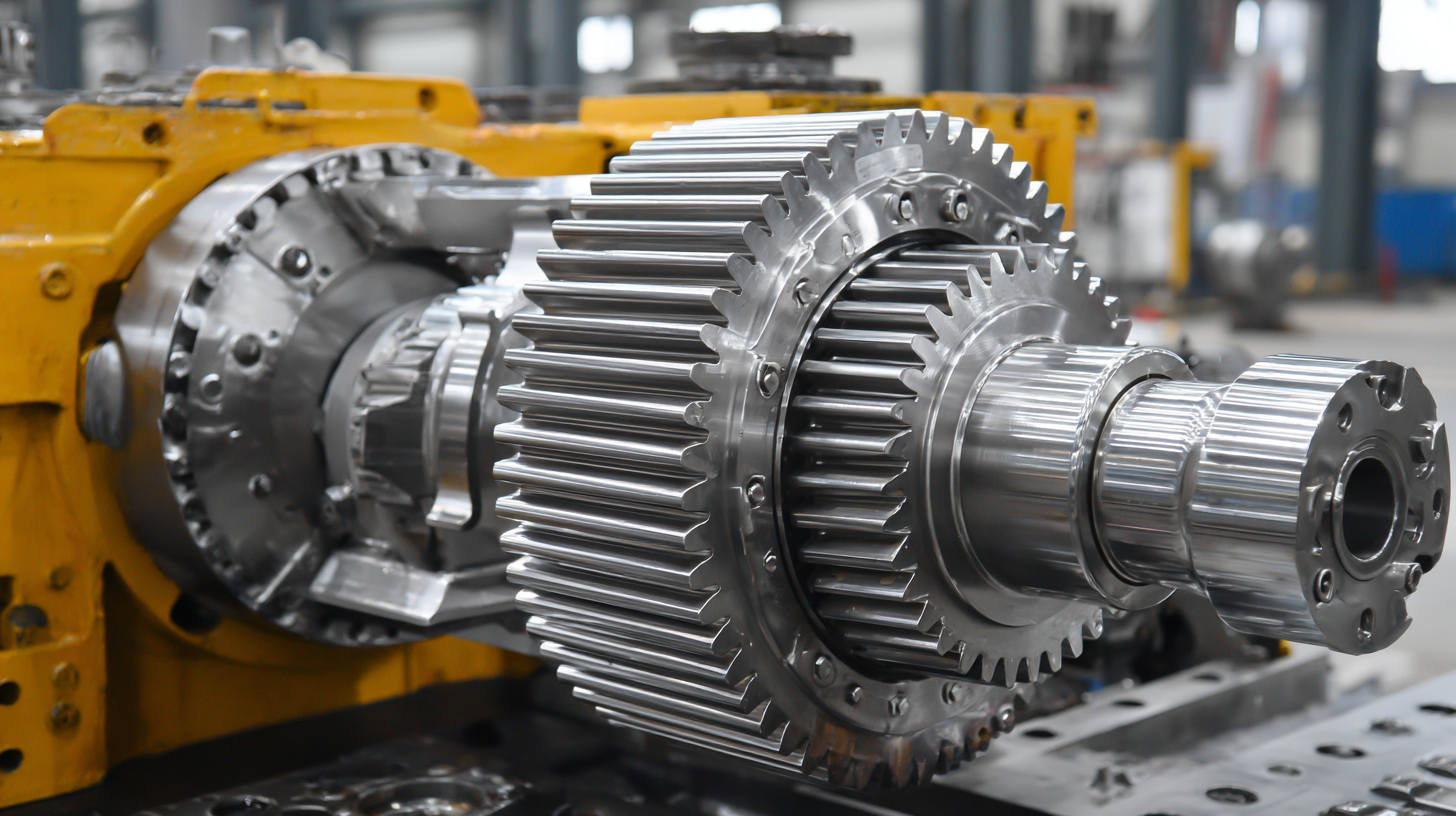

Different applications may require varying load capacities, depending on the nature and intensity of the work involved. For example, in heavy machinery or industrial applications, the considerations for load capacity become even more pronounced. Engineers often need to analyze the expected loads and select a gearbox that not only meets these requirements but also provides a safety margin for unpredictable circumstances. This careful calibration between the gearbox's specifications and the application's load demands ensures optimal performance and durability, allowing for smoother operation and reduced maintenance costs over time.

Recent Innovations in Planetary Gear Technology: Trends and Future Directions

Recent advancements in planetary gear technology have significantly transformed the landscape of various industries, particularly in automation, automotive, and renewable energy sectors. According to a report by Research and Markets, the global planetary gearbox market is projected to reach $7.8 billion by 2025, growing at a CAGR of 6.5%. This growth is largely driven by the increasing demand for compact and efficient power transmission systems, which are often achieved through the innovative design of planetary gears. These gears offer high torque density and reduced overall weight, making them ideal for applications ranging from electric vehicles to industrial machinery.

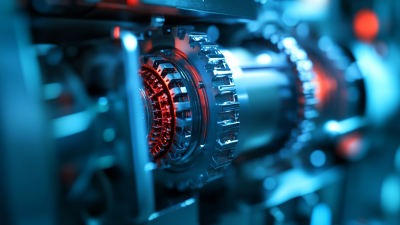

Moreover, ongoing innovations in materials and manufacturing processes are pushing the boundaries of planetary gearbox capabilities. For instance, the introduction of advanced composites and additive manufacturing techniques is enabling the production of lighter, stronger components that enhance durability and performance. The adoption of smart technology, such as IoT-enabled sensors, allows for real-time monitoring and predictive maintenance, which is increasingly necessary in high-demand applications. As industries strive for greater efficiency and sustainability, these innovations are likely to drive the future direction of planetary gearbox technology, solidifying its pivotal role in modern engineering solutions.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor