Discover the Unique Benefits and Applications of the Best Geared Servomotor for Global Industries

In today's rapidly evolving industrial landscape, the demand for precision and efficiency has never been greater. As companies strive to optimize their operations, the role of advanced technologies becomes increasingly critical. Among these innovations, the Geared Servomotor stands out as a pivotal component for diverse applications across global industries. Its unique design and capabilities provide enhanced torque and speed control, making it an ideal choice for tasks that require high performance and reliability.

From robotics and automation to aerospace and manufacturing, the versatility of geared servomotors allows for seamless integration into various systems, revolutionizing how businesses operate. In this blog, we will explore the unique benefits of the best geared servomotors available today, delving into their applications and the transformative impact they can have on industrial processes.

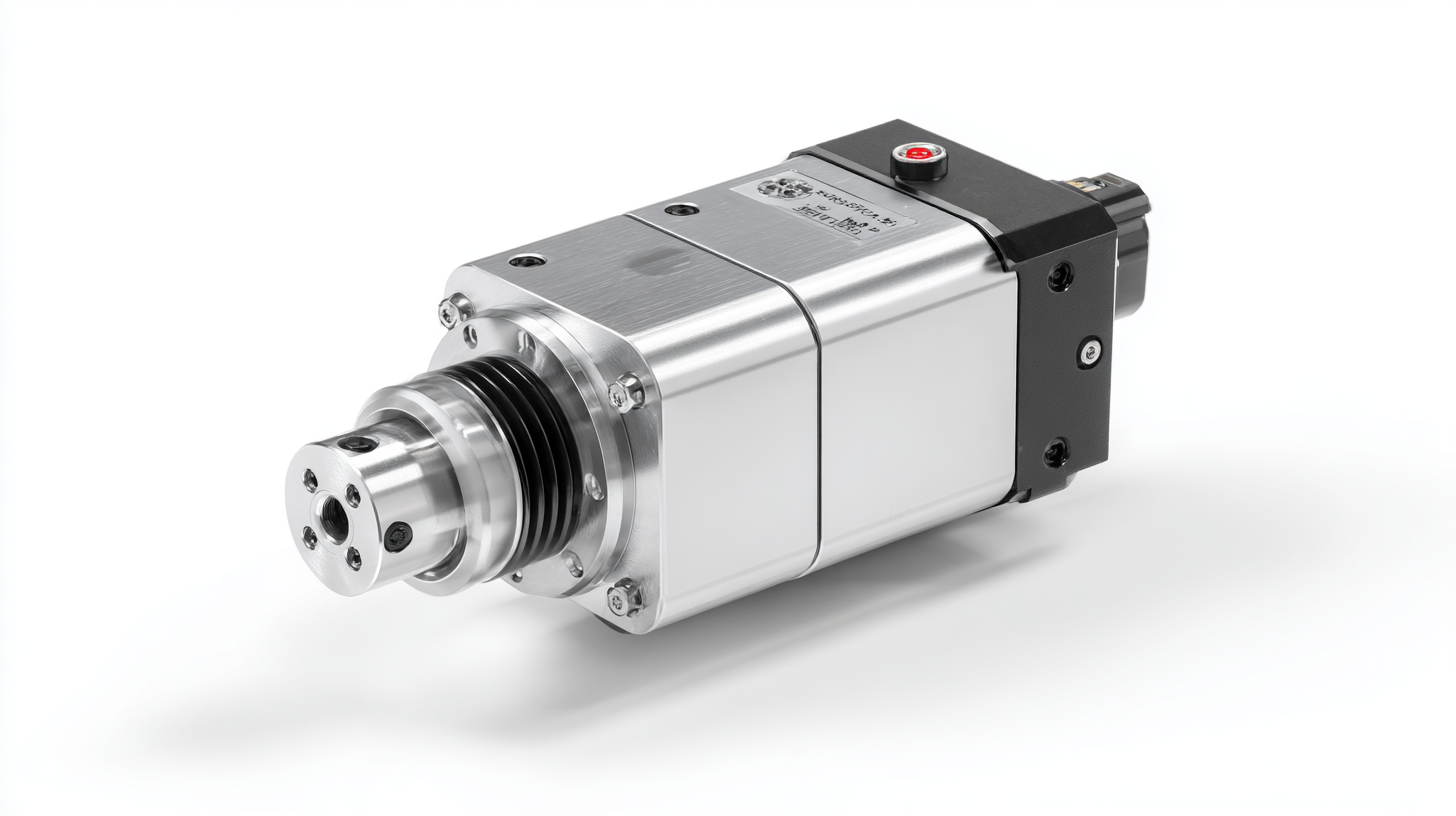

Exploring the Essential Features of Geared Servomotors for Industrial Applications

Geared servomotors are pivotal in a wide array of industrial applications, characterized by their ability to provide precise motion control while optimizing torque and speed. According to a report by Research and Markets, the global servomotor market is projected to reach $8.5 billion by 2025, driven by the demand for efficiency and precision in automated processes. The essential features of geared servomotors include high torque density, excellent responsiveness, and low backlash, making them ideal for robotics, CNC machinery, and conveyor systems.

**Tip:** When selecting a geared servomotor, consider the application's specific torque requirements and speed profiles. This ensures that the motor can meet operational demands without exceeding limits, enhancing reliability and longevity.

Geared servomotors also offer significant energy efficiency, which is increasingly crucial in modern manufacturing. A study published in the Journal of Manufacturing Science and Engineering found that using high-efficiency servomotors can reduce energy consumption by up to 25% in automated systems. This not only lowers operational costs but also aligns with sustainability goals within industries.

**Tip:** Regularly assess the performance of your servomotors and explore options for upgrades or replacements with newer models that feature advanced energy-saving technologies. This proactive approach can contribute to both cost savings and enhanced performance over time.

Unique Benefits and Applications of Geared Servomotors

This chart illustrates the unique benefits associated with geared servomotors across various essential features for industrial applications, highlighting their importance in global industries.

How Geared Servomotors Enhance Precision in Automation Processes

In the realm of automation, precision is paramount, and geared servomotors stand out as a critical component in achieving this goal. Their unique design integrates a gear mechanism, which allows for a reduction in speed while simultaneously increasing torque. This balance of power and precision is essential in various applications across global industries, from robotics to manufacturing. By providing greater control over the movement and positioning of machinery, geared servomotors enable more accurate and reliable operations.

Moreover, geared servomotors excel in applications requiring intricate movements, suchspan style="text-decoration: underline; color: #5bc0de;"> such as CNC machines and robotic arms. The enhanced torque output allows these devices to handle heavier loads without sacrificing speed or accuracy. This capability not only improves efficiency but also reduces wear and tear on components, leading to longer service life and lower maintenance costs. As industries continue to evolve, the adoption of geared servomotors in automation processes ensures that businesses remain competitive by optimizing their productivity and precision.

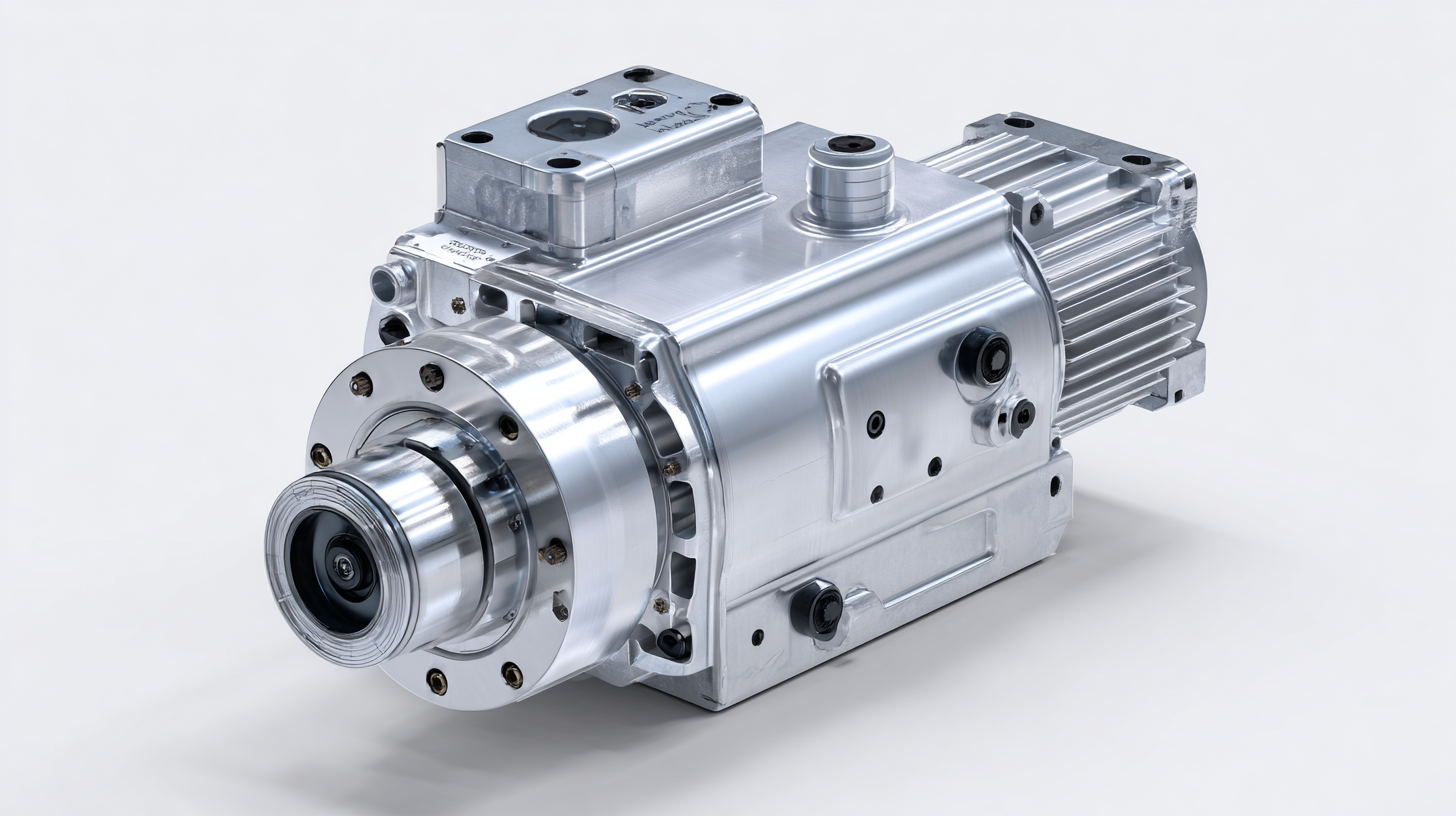

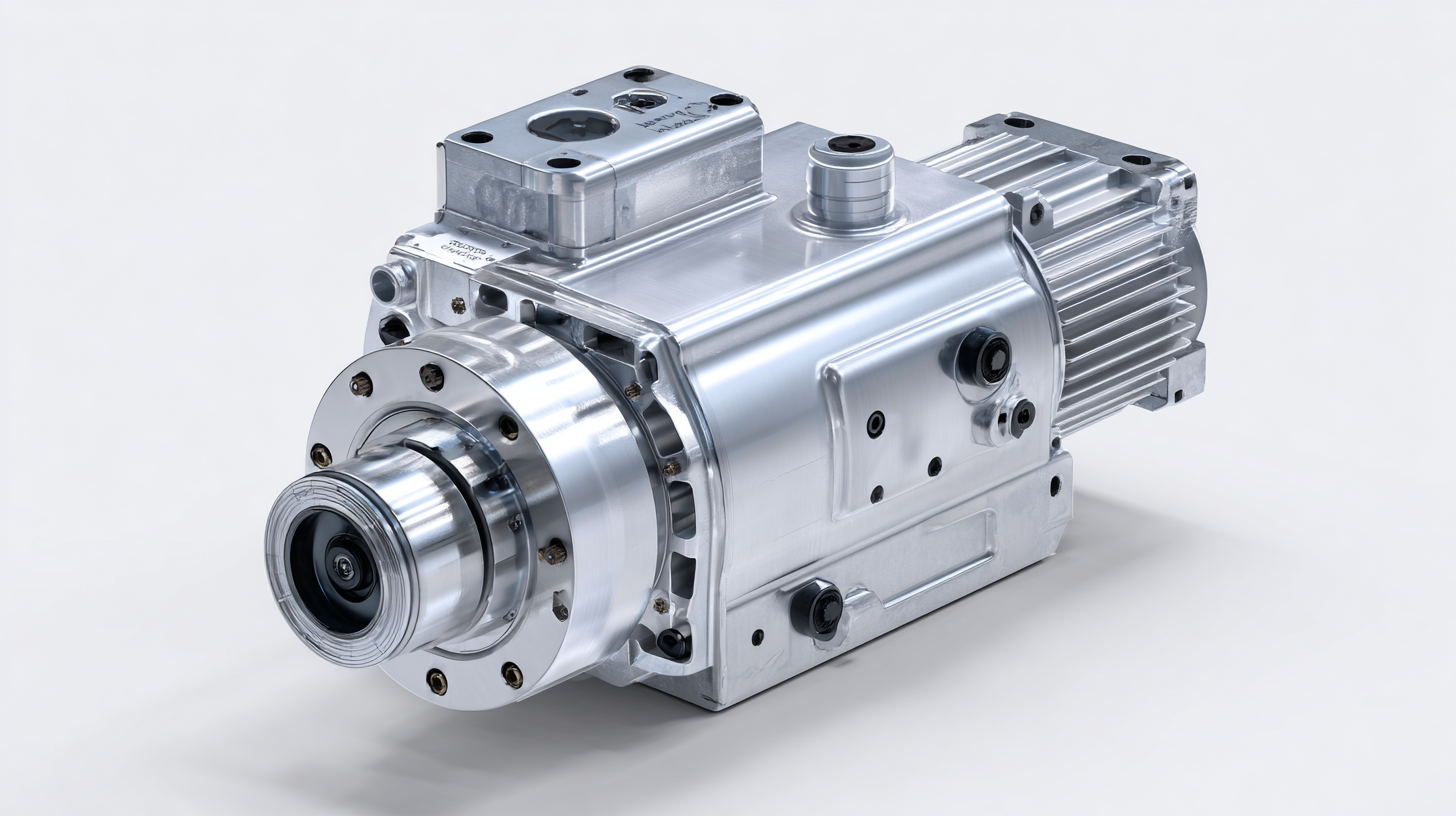

Top Industries Benefiting from Advanced Geared Servomotor Technology

Geared servomotors are making significant waves across various global industries due to their ability to provide precise control, high torque, and efficiency. The Integrated Servo Motor market is projected to reach substantial growth, driven by sectors such as automotive, aerospace, and manufacturing. According to recent industry analyses, the servo motors and drives market is estimated to hit USD 29.22 billion by 2034, fueled by the rising demand for automation and enhanced motor control devices.

Industries like automotive are leveraging geared servomotor technology to enhance production speeds and improve the accuracy of assembly processes. With advancements in AC and DC servo motors, manufacturers are experiencing remarkable efficiency gains, making operations more streamlined. For instance, automation in manufacturing is not just a trend—it's a necessity for survival in today’s market, leading companies to invest heavily in servo technologies to stay competitive.

Tips: When selecting a geared servomotor, consider the specific voltage requirements and the type of application it will serve. Additionally, evaluate the torque capabilities to ensure optimal performance in your industry. Embracing the latest servo technology can lead to significant operational improvements and cost savings.

Key Advantages of Using Geared Servomotors Over Traditional Motors

Geared servomotors have emerged as critical components in numerous global industries, delivering distinct advantages over traditional motors. One of the primary benefits of geared servomotors is their ability to provide precise control over speed and torque. By integrating gears into the motor system, these servomotors effectively multiply the output torque while reducing the speed. This capability is particularly valuable in applications that require high precision, such as robotics, CNC machinery, and automated assembly lines. Manufacturers can achieve increased efficiency and enhanced performance, securing a competitive edge in the market.

Another notable advantage of geared servomotors is their compact size and lightweight design, which make them suitable for applications with limited space. Compared to traditional motors, geared servomotors can offer a higher power-to-weight ratio, enabling the development of smaller machinery without sacrificing performance. This feature is especially crucial in industries like aerospace and automotive, where every ounce of weight counts. Furthermore, the smooth operation and reduced backlash characteristic of geared servomotors lead to improved reliability and longevity, minimizing maintenance costs and downtime for operators.

Innovative Applications of Geared Servomotors Across Global Markets

Geared servomotors are at the forefront of innovation in various global markets, showcasing unique applications that drive efficiency and precision across multiple industries. From manufacturing to robotics, these motors offer the torque and control necessary for high-performance tasks. Their ability to integrate into complex systems makes them indispensable in applications such as automated assembly lines and advanced robotics programs, where reliability and accuracy are crucial.

An excellent example of the versatility of geared servomotors can be seen in their use in specialized devices, such as micro-geared motors. These compact yet powerful motors find their application in cutting-edge technologies, including high-precision medical tools and automotive systems. For instance, in the defense sector, these motors are utilized in portable equipment, significantly enhancing operational capabilities. Similarly, in the automotive industry, they contribute to the seamless functioning of features like electronic door locks and sunroofs.

Tips: When selecting a geared servomotor for your application, consider the required torque and speed specifications to ensure optimal performance. Additionally, be mindful of the environment where the motor will operate, as factors such as temperature and humidity can affect functionality. Finally, look for manufacturers that offer customizable solutions to meet your unique needs, as this can lead to more efficient and effective applications.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor