- SIEMENS Gearmotor

- NORD Industrial Gear Unit

- LENZE Gearmotor

- NORD Gearmotor

- SEW Planetary Gear Unit

- SEW Industrial Gear Unit

- SEW Gearmotor

- BONFIGLIOLI Precision Planetary Gearbox and Gearmotor

- BONFIGLIOLI Inverters and Servo drives

- BONFIGLIOLI Industrial Gear Unit

- BONFIGLIOLI Gearmotor

- FLENDER Coupling

- FLENDER Gear Unit

01

N-ARPEX Torsionally Rigid All-Steel Coupling

Your benefits at a glance

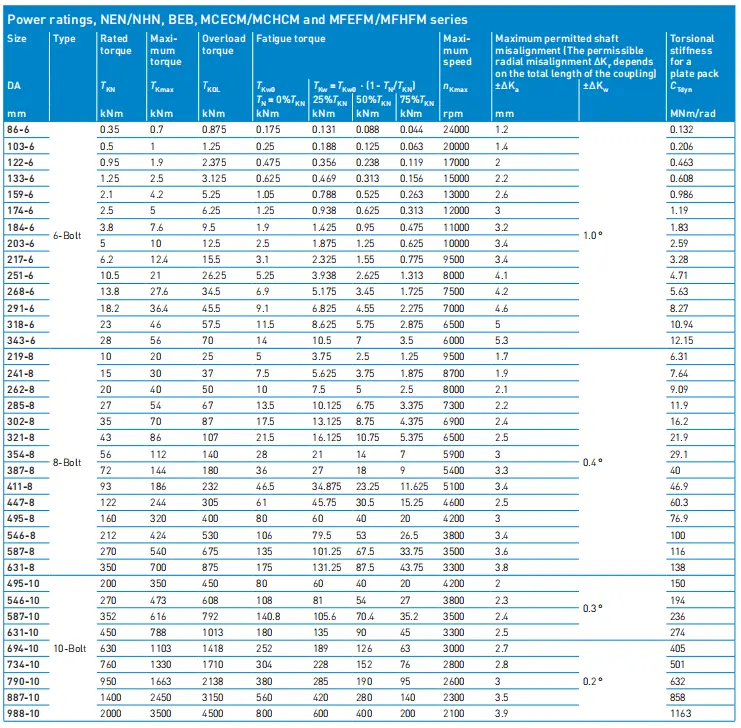

N-ARPEX couplings of the ARN-6/-8/-10 series are outstanding for their application-optimized construction.

The NEN, BEB, MCECM, MFEFM series meet the require ment of API 610. Coupling type in accordance with API 671is also possible. For speeds of over 1,800 rpm the five-part version with pre-assembled intermediate unit is used.

A special catching device acts to secure the interme diate spacer in the event of plate breakage. Application of the N-ARPEX couplings in potentially explosive atmospheres in accordance with the current ATEX Directive is permitted.

application

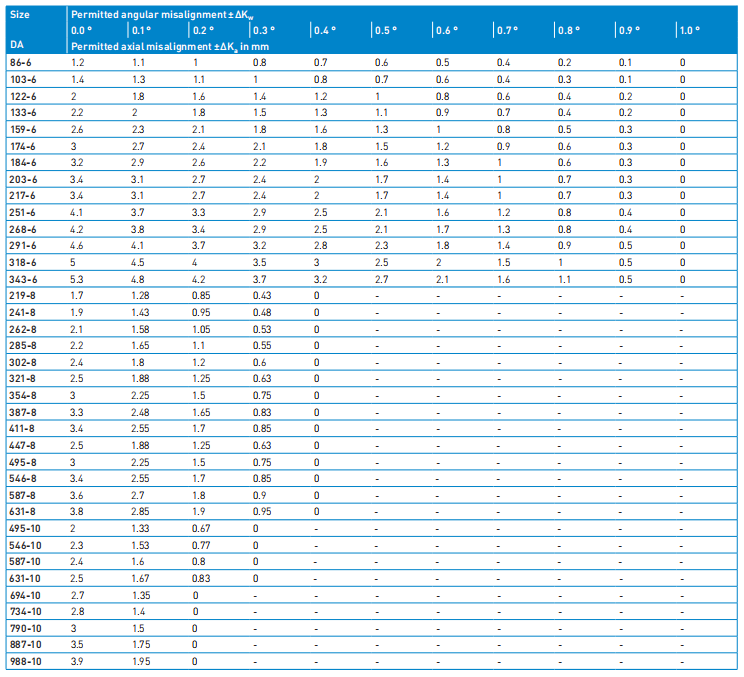

N-ARPEX couplings of the ARN-6/-8/-10 series are used wherever reliable torque transmission is called for, even

in cases of often unavoidable shaft misalignment. They are universally applicable over a temperature range of from -50 °C (or even as low as -60 °C on request) up to +280 °C, are torsionally rigid, free of torsional backlash and enable quiet running at a constant angular velocity. They are wear-free and maintenance-free and, if correctly fitted, can be expected to have an unlimited service life.

Especial consideration is given to use in pump and compressor drives. Available for this are couplings with standardised intermediate spacer lengths from stock (see following tables).

Main areas of application for the ARN-6/-8-/10 series:

• Pumps

• Fans

• Compressors

• Generator and turbine drives

• Axial and radial blowers

• Paper-making machines and printing machines

• Mixers, Stirrers

• Extruders

• Lifting and traversing gears

• Marine drive

• Water screw drives

By the launch of the new FLENDER N-ARPEX all-steel multiple-disk couplings Flender is continuing the success story of the proven ARPEX coupling series.

An optimised plate pack and a reworked component part design enable even higher torques and speeds to be transmitted.

In short, the new design of the plate packs, the closed flange geometry, the standard catching device of the intermediate spacer and FEM-optimised force distribution inside the all-steel multiple-disk coupling clearly show that the development has paid off.

Design and configurations

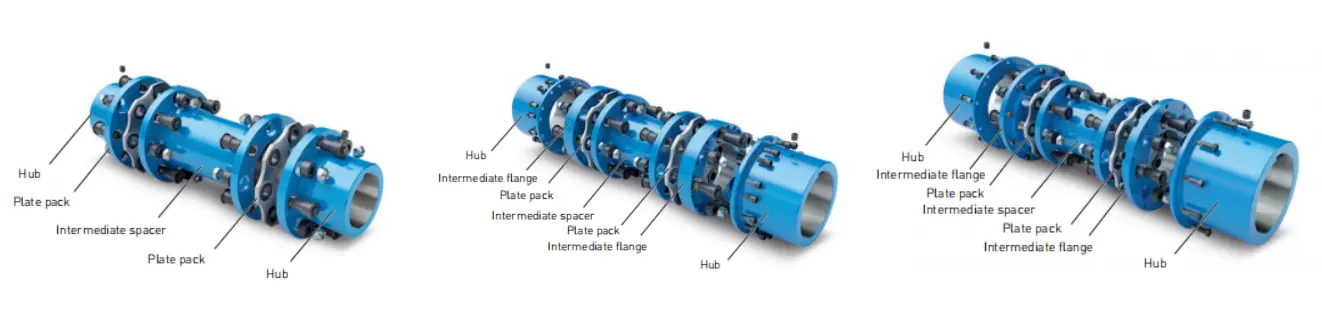

NEN

The design of an N-ARPEX type NEN is shown in the following illustration. The coupling comprises two hubs, an intermediate spacer and two plate packs that in the ARN-6 series are bolted together alternatingly with close-fitting bolts and in the ARN-8/-10 series by means of a Flender conical screw connection. The coupling is available in fixed lengths from stock. Other spacer lengths are manufactured to order. Hubs are designed with threaded pull-off holes.

MCECM

The design of an N-ARPEX type MCECM is shown in the following illustration. The coupling comprises two hubs and a pre-assembled intermediate unit (CEC), where

the plate packs are bolted together with an intermediate spacer and intermediate flanges at the factory. All that need be done at the construction site is to bolt the hubs

with the intermediate flanges. The coupling is available in fixed lengths from stock. Other spacer lengths are manufactured to order. Hubs are designed with threaded pull-off holes.

MFEFM

The following illustration shows the N-ARPEX type MFEFM. It most differs from the type MCECM by the considerably increased bore capacity, for which reason this type is intended precisely for comparatively large shaft diameters. The coupling is available in fixed lengths from stock. Other spacer lengths are manufactured to order. Hubs are designed with threaded pull-off holes

Plate-pack designs

The plate packs of the N-ARPEX ARN series are designed with hexagon, octagon and decagon plates, depending on the coupling size. The number of screw connections is indicated in the denomination of the ARN-6/-8/-10 series.

Hexagon plates have 6 bolting points, octagon plates have 8 bolting points and decagon plates have 10 bolting points.

The hexagon plates, octagon plates and decagon plates up to size 631 are designed as ring plates. Sizes 694 to 988 are designed as segmented plates.

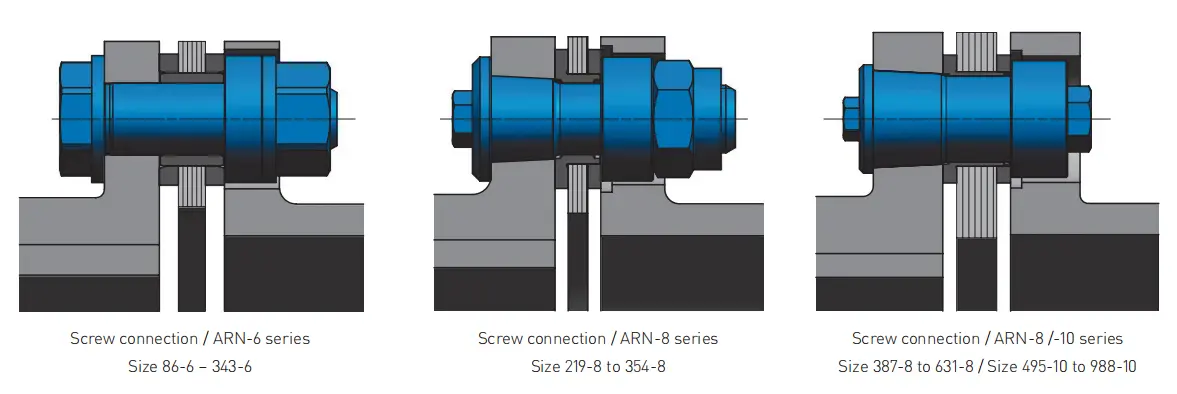

Plate pack screw connection

In the ARN-6 series the plate pack screw connection on N-ARPEX couplings is designed in the form of a close fitting screw connection. In the ARN-8 and ARN-10 series a

conical bolt connection by Flender is used.

The advantage of this screw connection is the considerably simplified installation in the case of large screw connections.

specifications

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150 SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage SIEMENS SINAMICS V90

SIEMENS SINAMICS V90 SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage FLENDER Gear Unit

FLENDER Gear Unit FLENDER Helical Gear Unit

FLENDER Helical Gear Unit Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox Playmaker In The Premium League

Playmaker In The Premium League Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200 Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships Reliable Power Generation on board

Reliable Power Generation on board Maximum performance level, fast deliverable

Maximum performance level, fast deliverable Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable. FLENDER Coupling

FLENDER Coupling ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance SEW Gearmotor

SEW Gearmotor R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor